Automatic numerically-controlled final trimming and dust collecting device for PVC sheets

A dust collector and automatic technology, applied in the direction of removing smoke and dust, transportation and packaging, conveyors, etc., can solve the problems of physical health hazards of operators, large plate size errors, low material utilization rate, etc., to shorten the cutting time, The effect of high cutting precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

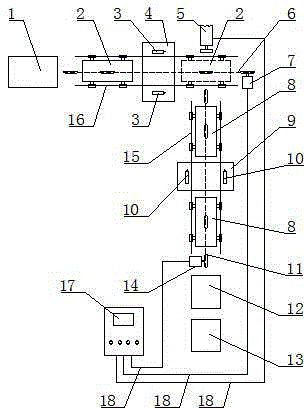

[0007] see figure 1 , the present invention includes a material platform 1, a transverse track trolley 2, two transverse cutting hobs 3 symmetrically arranged up and down, a transverse cutting dust cover 4, an electric pushing device 5, a transverse sprocket transmission mechanism 6, and a transverse sprocket drive servo Motor 7, longitudinal track trolley 8, longitudinal cutting vacuum cover 9, two longitudinal cutting hobs arranged symmetrically from left to right 10, longitudinal sprocket transmission mechanism 11, finished product table 12, automatic packing machine 13, longitudinal sprocket drive servo motor 14 , two longitudinal guide rails 15 arranged in parallel, two transverse guide rails 16 arranged in parallel, an electric control box 17 and a wire 18, a programmable logic controller PLC is housed in the electric control box 17, and the electric control box 17 passes through Conductor 18 is respectively connected with electric pushing device 5, transverse sprocket d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com