Tool parameter measurement device based on CCD and measurement method of device

A technology for parameter measurement and tooling, which is used in measurement/indication equipment, manufacturing tools, metal processing equipment, etc., and can solve problems such as reduced efficiency and accuracy impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

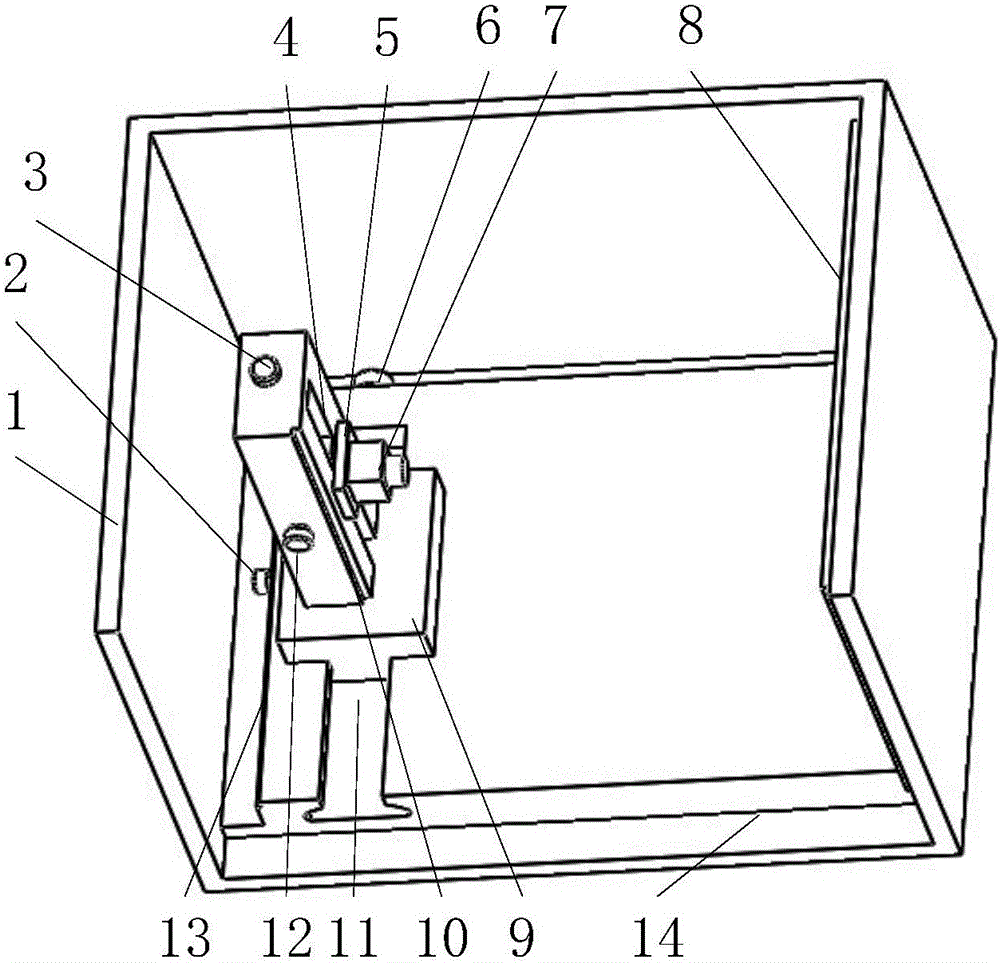

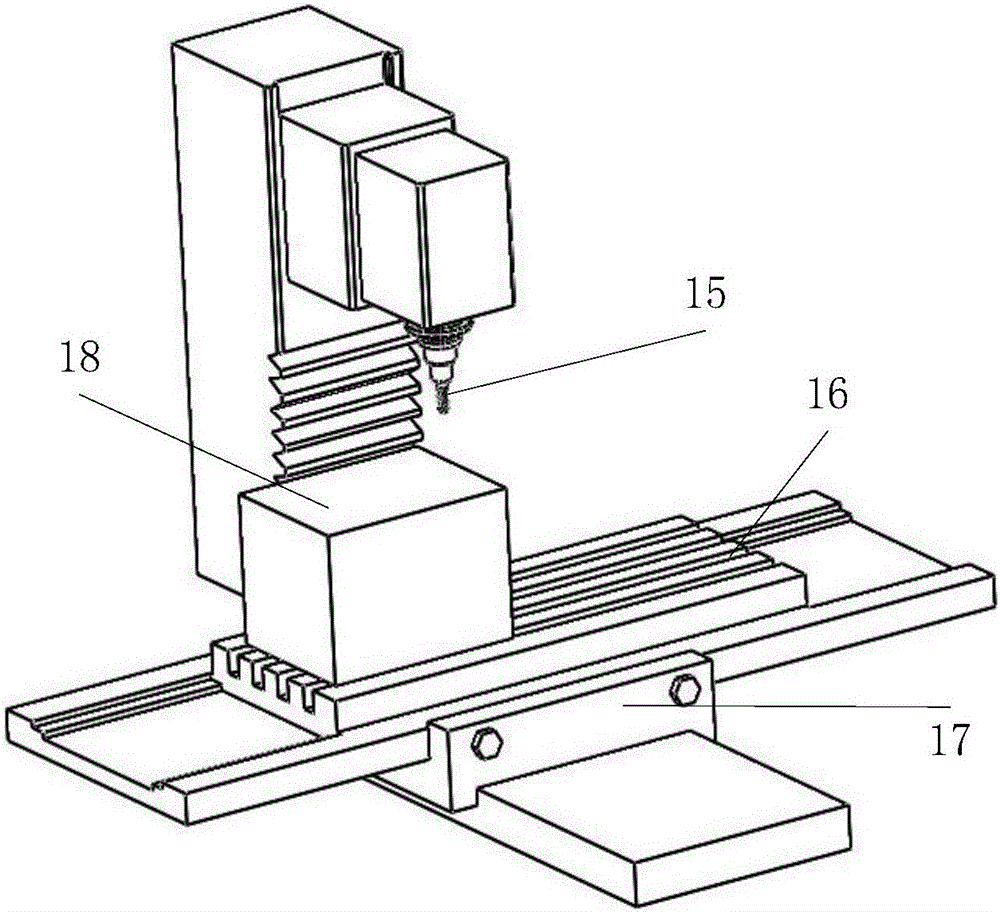

[0049] like figure 1Shown, the tool parameter measuring device based on CCD of the present invention comprises acquisition box 18, CCD industrial camera 7, industrial computer (not shown in the figure) and display (not shown in the figure), CCD industrial camera 7, industrial computer and display Connect sequentially. Collection box 18 is to be provided with casing 1 on its base 14 and forms, and casing 1 comprises four side box doors and a top box door ( figure 1 The top box door and one side box door are omitted in the middle), and each box door is movable and can be opened. The base 14 of the collection box 18 is provided with a camera lateral movement mechanism, the camera lateral movement mechanism is provided with a camera longitudinal movement mechanism, and the CCD industrial camera 7 is installed on the camera longitudinal movement mechanism. The LED light source board 8 is also arranged in the collection box 18, and the LED light source board 8 is used for lighting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com