Special equipment for machining head of air intake welding manifold of automobile

A special equipment and manifold technology, which is applied in the field of special equipment for processing the head of the automobile intake welding manifold, can solve the problems of affecting the production and processing efficiency, affecting the processing accuracy, and violent vibration, so as to facilitate cleaning and processing and improve work safety degree, the effect of increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

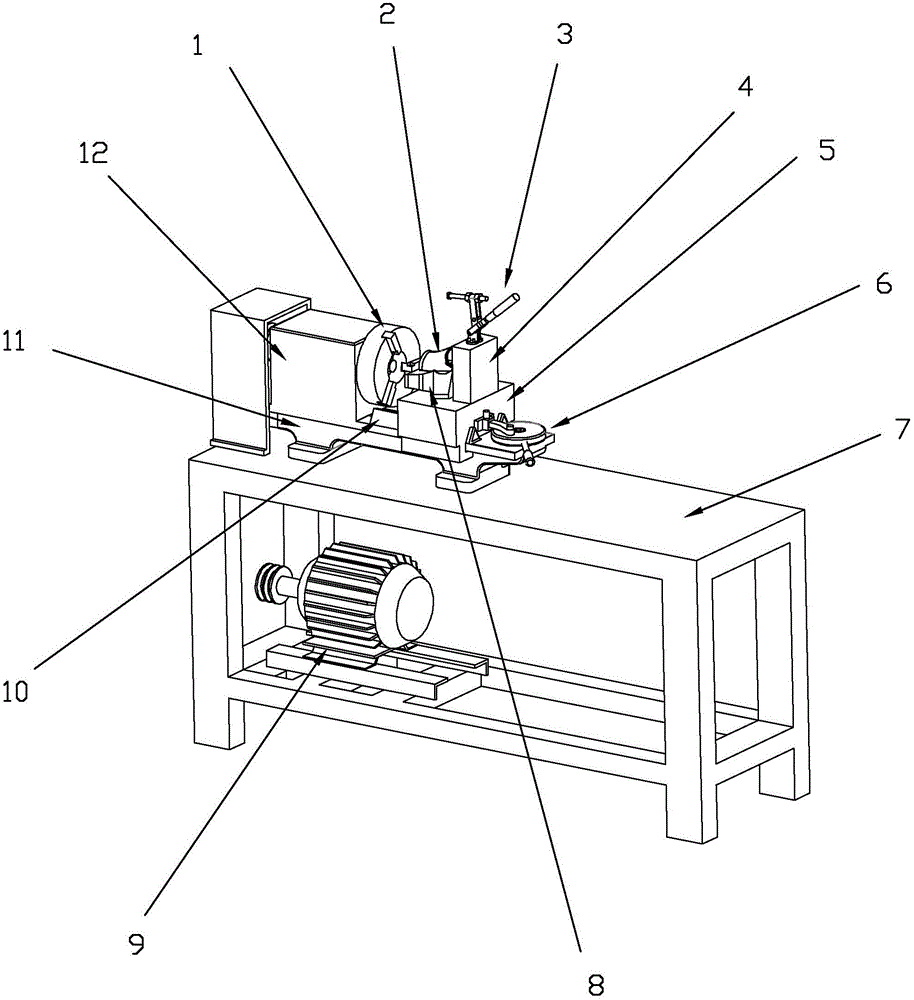

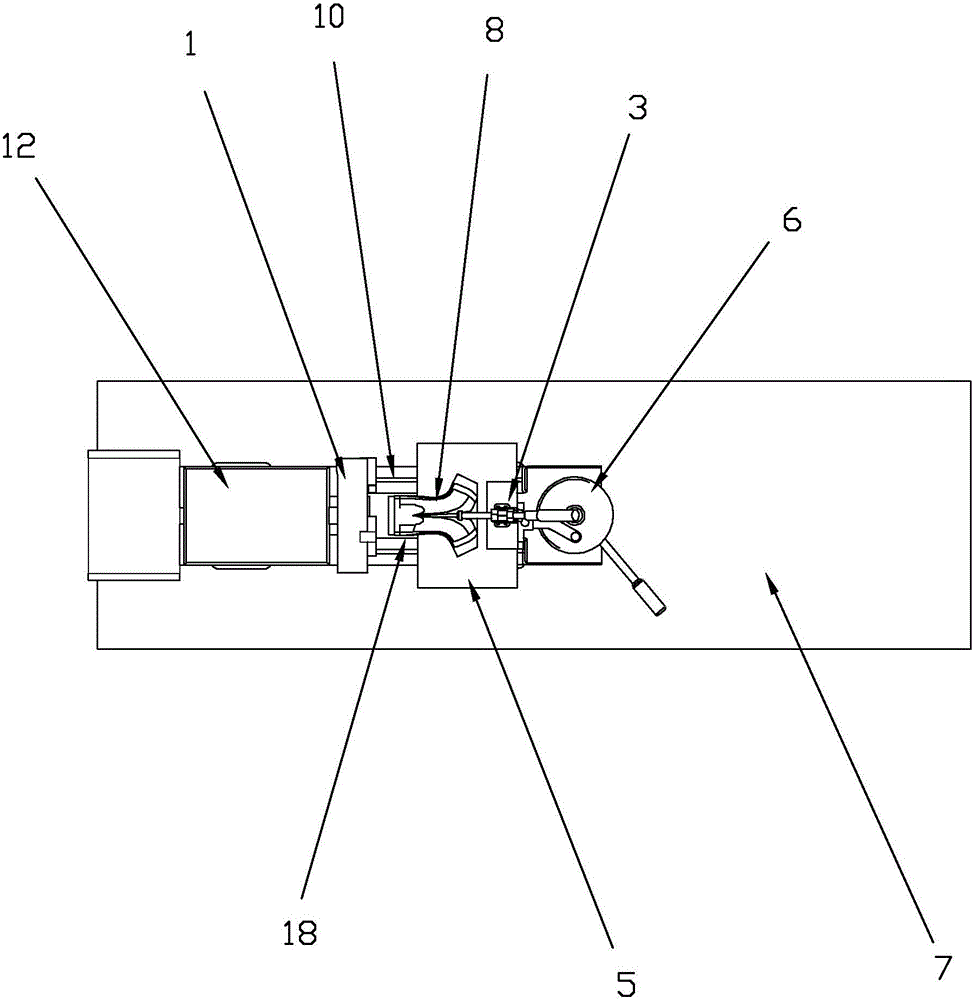

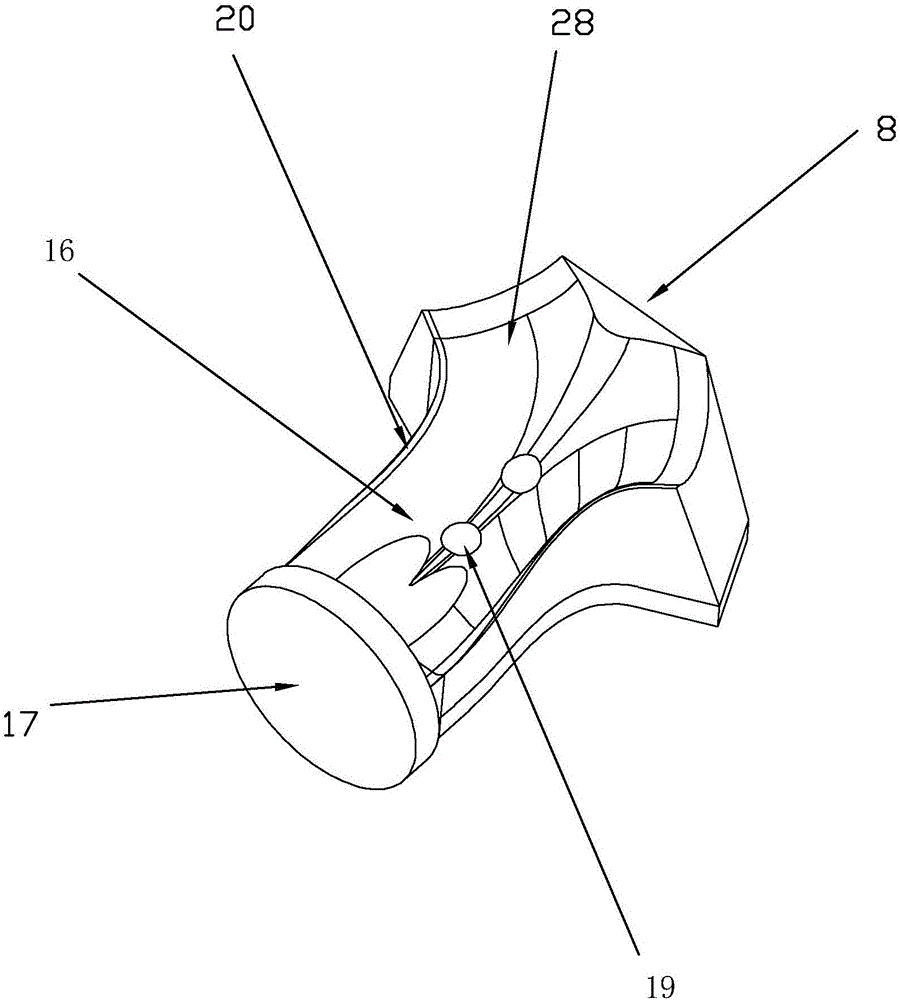

[0039] Such as figure 1 As shown, a special equipment for processing the head of an automobile intake welding manifold includes a frame body 7, a bed 11 is provided on the frame body 7, a slide rail 10 is provided on the bed 11, and a cutter head located at one end of the slide rail 10 1 and the driving device 6 positioned at the other end of the slide rail 10, the slide rail 10 is slidably connected with a workpiece holder 5, the workpiece holder 5 is provided with a fixed block 8 for fixing the manifold 2 to be processed, and is also provided with a workpiece The fixed block 8 cooperates and fastens the fixture 3 of the manifold 2 to be processed, and the surface of the cutter head 1 facing the workpiece holder 5 is provided with an inner cavity 14 for the manifold head to extend into, and the opening edge of the inner cavity 14 is evenly distributed for T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com