Automatic feeding and discharging device for window punching of tapered roller bearing retainers

A technology of tapered roller bearings and cages, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of hidden safety hazards and low efficiency, and achieve the effects of ensuring safety, easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

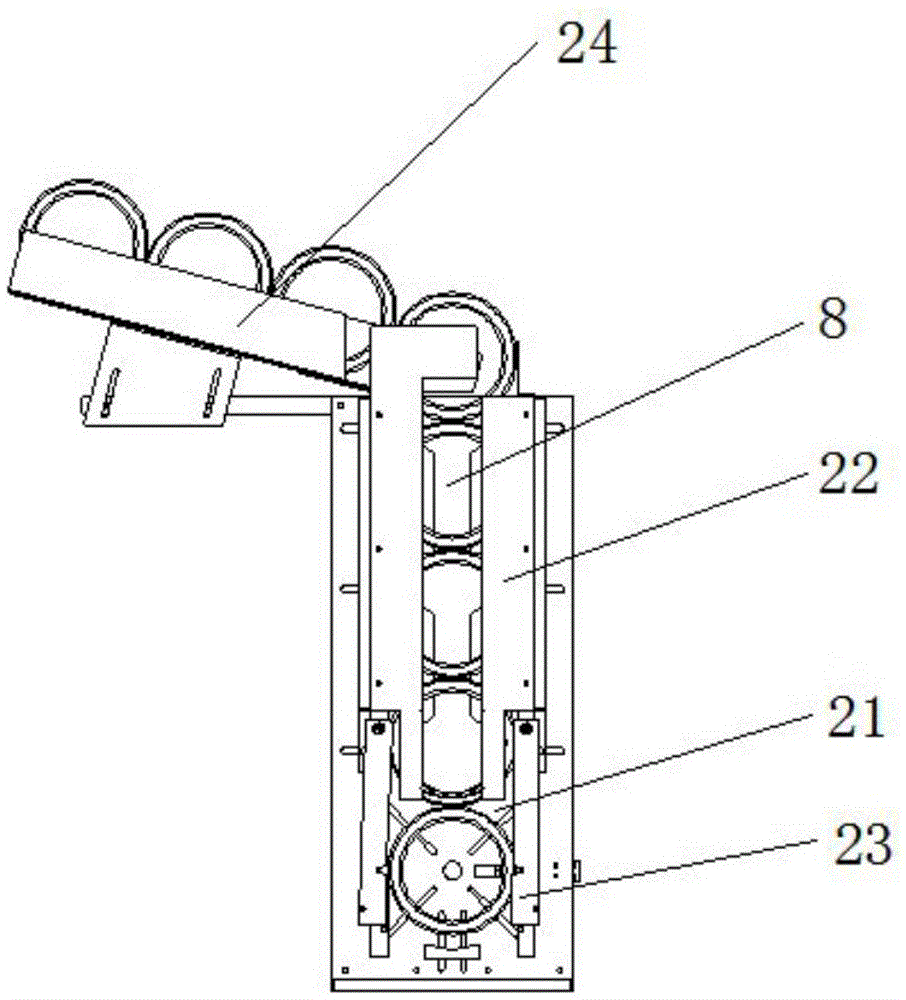

[0040] In this example, see image 3 , The feed inlet at the top of the feed channel groove 21 is provided with a transverse guide groove 24 obliquely. The purpose is to make use of the design of the transverse guide groove 24 to facilitate the placement of the tapered roller bearing cage 8. Under the action of gravity, the tapered roller bearing cage 8 in the transverse guide groove 24 will move along with its inclination. Slide downwards, and after entering the feed channel groove 21, it can wait for post-processing. A large number of cages can be processed continuously at one time. Of course, other material guide mechanisms can also be used according to the needs of use.

Embodiment 2

[0042] In this example, see Figure 5 , The circular chuck 32 is uniformly provided with clamping jaw brackets 35 , and the clamping jaws 33 are pivotally connected to the clamping jaw brackets 35 through the rotating shaft 36 and the snap spring 37 . The purpose is that the clamping structure can conveniently and stably grasp the cage of the tapered roller bearing, and can be applied to cages of different sizes and models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com