Flexible fiber shearing machine and shearing method

A flexible fiber and shearing machine technology, used in metal processing, grain processing, etc., can solve the problems of machine failure, flexible fiber winding, and large volume of flexible fibers, achieving the effect of neat section, avoiding mutual entanglement and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments.

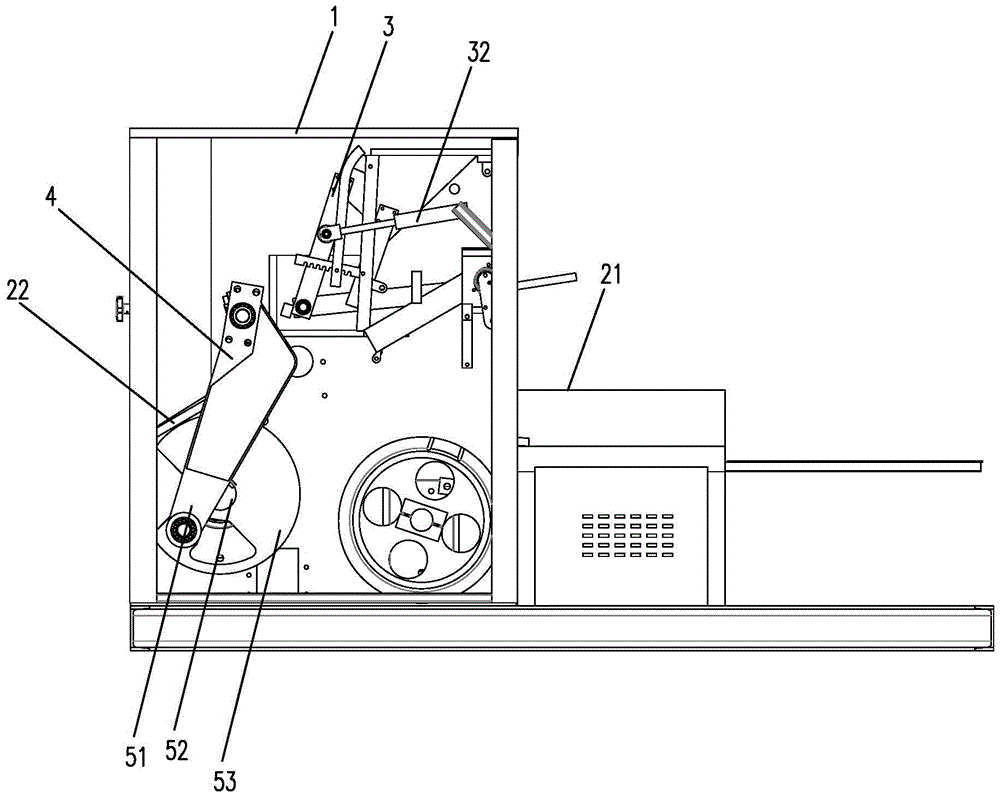

[0021] refer to Figure 1 to Figure 3 As described above, the flexible fiber shearing machine includes a housing 1, a feeding channel 2, a pressing device 3, a cutter 4, and a cutter driving mechanism 5;

[0022] The feeding channel 2 penetrates into the housing 1, and its two ends are the feeding port 21 and the feeding port 22 respectively;

[0023] The pressing device 3 includes a pressing roller 31 and a pressing roller driving mechanism 32, the pressing roller 31 is provided with a plurality, and the plurality of pressing rollers 31 are arranged in parallel along the feeding passage 2 above the feeding passage 2, the pressing roller The roller driving mechanism 32 is respectively connected with a plurality of nip rollers 31 to drive the nip rollers 31 to rotate toward the outlet, for pressing the flexible fibers on the feeding channel 2 and driving them to move toward the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com