Ball-milling mechanical device

A mechanical device and ball milling technology, applied in the direction of grain processing, etc., can solve the problems of difficult to grasp the size of the crushing particle size, reduce the service life of the equipment, and difficult to control the airflow speed, and achieve the effect of simple structure, improved production efficiency, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

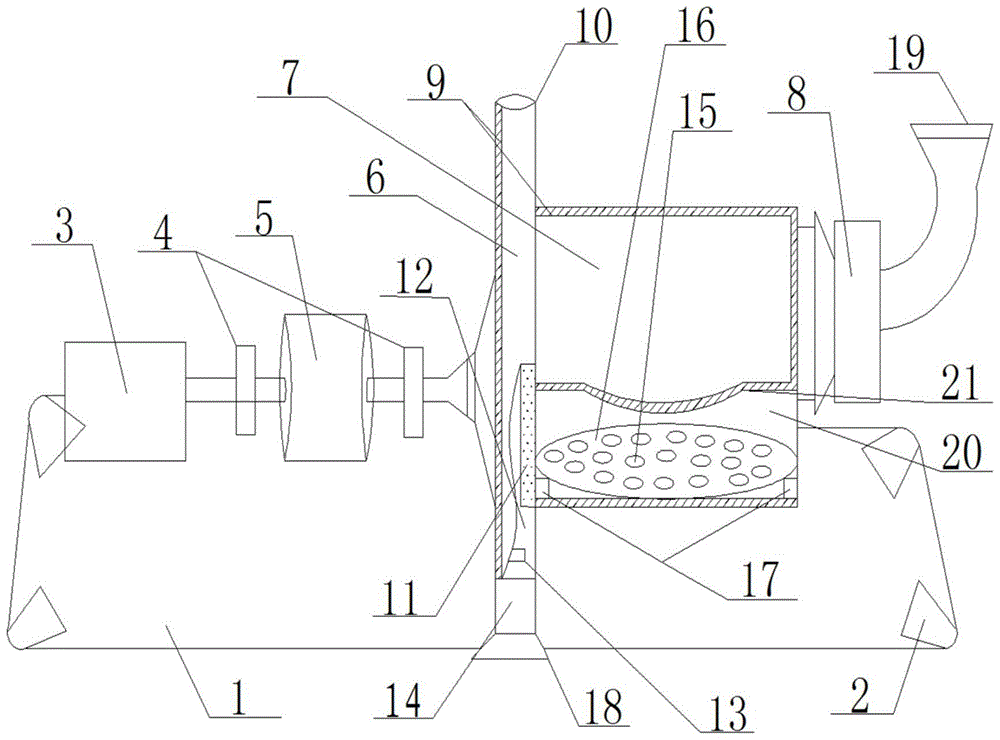

[0016] Such as figure 1 As shown, a ball mill mechanical device of the present invention includes a base 1, a motor 3, a reducer 5 and a box body 7, the four corners of the base 1 are respectively provided with legs 2, the motor 3 is fixed on the base 1, and the motor 3 is connected to One end of the reducer 5, the other end of the reducer 5 is fixedly connected to one side of the column 6, the other side of the column 6 is fixedly connected to the box body 7, the top of the column 6 is provided with a ventilation hole 10, and the connection between the column 6 and the box body 7 is provided with a discharge plate 11 , the discharge plate 11 is connected to the discharge chamber 12, the discharge chamber 12 is connected to the collecting cover 14, the connection between the column 6 and the discharge chamber 12 is provided with a material rejection hole 13, and the box body 7 is connected to the feed port through the air velocity control device 8 19. The lower half of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com