Composite adsorption membrane, preparation method and application thereof

A composite adsorption and composite hydroxide technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of secondary pollution of water bodies, difficult recovery, etc., and achieve simple preparation process and heavy experimentation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

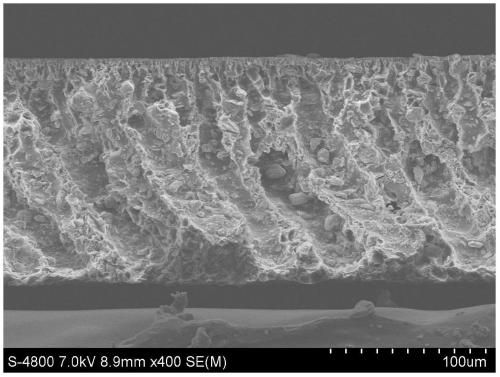

[0026] (1) Add 18 parts by weight of polysulfone to 73 parts by weight of N,N-dimethylformamide, and vigorously stir at 65° C. for 2 hours to obtain a transparent organic solution.

[0027] (2) Add 9 parts by weight of the layered magnesium-aluminum composite hydroxide to the above organic solution, and vigorously stir at 65° C. for 24 hours to obtain a casting solution in which the layered magnesium-aluminum composite hydroxide is uniformly dispersed.

[0028] (3) At room temperature, the above-mentioned casting solution was evenly coated on a clean glass plate, and immediately immersed in deionized water to obtain a composite film with a thickness of 150 μm, which was dried at 70° C. and stored.

[0029] (4) Weigh 0.3g of dry composite membrane and place it in 50mL of high-fluorine water with a concentration of 10mg / L; after static adsorption at 25°C for 2.5 hours, the removal rate of fluoride ion was measured to be 66.3%, and the composite membrane’s fluoride ion The equili...

Embodiment 2

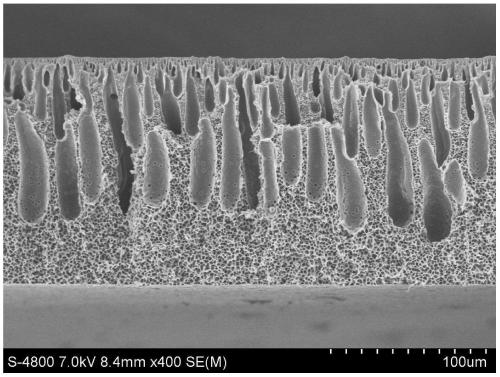

[0031] (1) Add 16 parts by weight of polyethersulfone to 67 parts by weight of N,N-dimethylacetamide, and vigorously stir at 65° C. for 2 hours to obtain a transparent organic solution.

[0032] (2) Add 17 parts by weight of the layered magnesium-aluminum composite hydroxide to the above organic solution, and vigorously stir at 65° C. for 24 hours to obtain a casting solution in which the layered magnesium-aluminum composite hydroxide is uniformly dispersed.

[0033] (3) At room temperature, evenly coat the above-mentioned casting solution on a clean glass plate, and immediately immerse in deionized water to obtain a composite film with a thickness of 150 μm, dry at 70°C, and store.

[0034] (4) Weigh 0.3g of dry composite membrane and place it in 50mL of high-fluorine water with a concentration of 10mg / L; after static adsorption at 25°C for 2.5 hours, the removal rate of fluoride ion was measured to be 87.1%, and the composite membrane’s fluoride ion The adsorption amount was...

Embodiment 3

[0036] (1) Add 14 parts by weight of polyethersulfone to 57 parts by weight of N,N-dimethylformamide, and vigorously stir at 65° C. for 2 hours to obtain a transparent organic solution.

[0037] (2) Add 29 parts by weight of the layered magnesium-aluminum composite hydroxide to the above organic solution, and vigorously stir at 65° C. for 24 hours to obtain a casting solution in which the layered magnesium-aluminum composite hydroxide is uniformly dispersed.

[0038] (3) At room temperature, evenly coat the above-mentioned casting solution on a clean glass plate, and immediately immerse in deionized water to obtain a composite film with a thickness of 150 μm, dry at 70°C, and store.

[0039] (4) Weigh 0.2g of dry composite membrane and place it in 50mL of high-fluorine water with a concentration of 10mg / L; after static adsorption at 25°C for 2.5 hours, the removal rate of fluoride ion was measured to be 91.0%, and the composite membrane’s fluoride ion The adsorption capacity w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com