Moringa oleifera leaf drying method

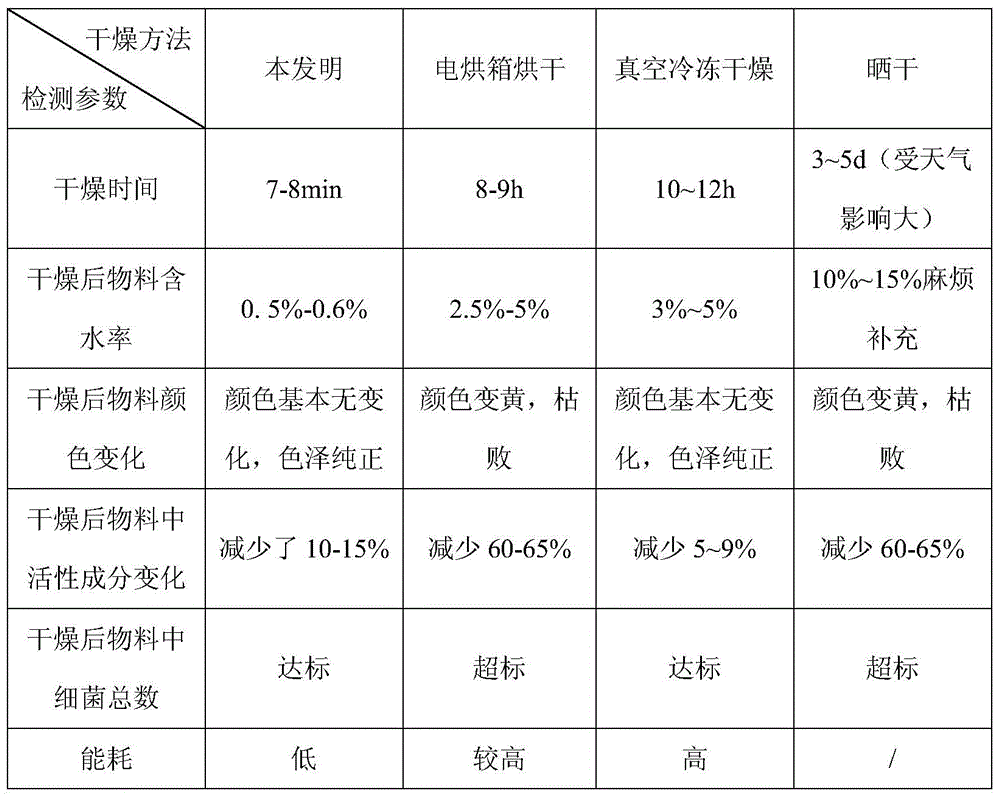

A drying method and technology of Moringa oleifera leaves, applied in the direction of preserving fruits/vegetables through dehydration, can solve the problems of high nutritional quality of Moringa oleifera leaf powder, long drying cycle, low efficiency, etc., saving manpower and material resources, short drying cycle, Complete drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for drying Moringa leaves, comprising the following steps:

[0024] (1) Send fresh Moringa leaves into the cloth bin of microwave drying equipment, carry out mechanical distribution, and spread Moringa leaves on the transmission belt of microwave drying equipment; the thickness of Moringa leaves on the transmission belt after the cloth is 0.4 cm, the width is 75cm;

[0025] (2) The Moringa leaves after the cloth are sent to the microwave cavity of the microwave drying equipment, and microwaves are used to dry, and at the same time, the moisture in the microwave cavity of the microwave drying equipment is discharged with a dehumidifier; When the moisture content of the leaves is 3%, discharge is carried out, and the discharge temperature is 55°C; wherein, the microwave power density of the microwave drying equipment is 12kW / m 2 , the exhaust volume of the dehumidifier is 4000m 3 / h, the dehumidifier is a centrifugal fan;

[0026] (3) sending the Moringa leave...

Embodiment 2

[0028] A method for drying Moringa leaves, comprising the following steps:

[0029] (1) Send fresh Moringa leaves into the cloth bin of microwave drying equipment, carry out mechanical distribution, and spread Moringa leaves on the transmission belt of microwave drying equipment; the thickness of Moringa leaves on the transmission belt after the cloth is 1.2 cm, the width is 90cm;

[0030] (2) The Moringa leaves after the cloth are sent to the microwave cavity of the microwave drying equipment, and microwaves are used to dry, and at the same time, the moisture in the microwave cavity of the microwave drying equipment is discharged with a dehumidifier; When the moisture content of the leaves is 0.5%, discharge is carried out, and the discharge temperature is 45°C; wherein, the microwave power density of the microwave drying equipment is 8kW / m 2 , the exhaust volume of the dehumidifier is 10000m 3 / h, the dehumidifier is a centrifugal fan;

[0031] (3) sending the Moringa lea...

Embodiment 3

[0033] A method for drying Moringa leaves, comprising the following steps:

[0034] (1) Fresh Moringa leaves are sent into the cloth bin of microwave drying equipment, and mechanical cloth is carried out, and Moringa leaves are tiled on the transmission belt of microwave drying equipment; the thickness of Moringa leaves on the transmission belt after the cloth is 1cm , the width is 80cm;

[0035] (2) The Moringa leaves after the cloth are sent to the microwave cavity of the microwave drying equipment, and microwaves are used to dry, and at the same time, the moisture in the microwave cavity of the microwave drying equipment is discharged with a dehumidifier; When the moisture content of the leaves is 1.5%, discharge is carried out, and the discharge temperature is 50°C; wherein, the microwave power density of the microwave drying equipment is 10kW / m 2 , the exhaust volume of the dehumidifier is 8000m 3 / h, the dehumidifier is a centrifugal fan;

[0036] (3) sending the Mori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com