Modular aeration device

A ventilation device, gas technology, applied in mixers with rotating stirring devices, biochemical instruments, transportation and packaging, etc., can solve problems such as troublesome, expensive and ineffective sterilization procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

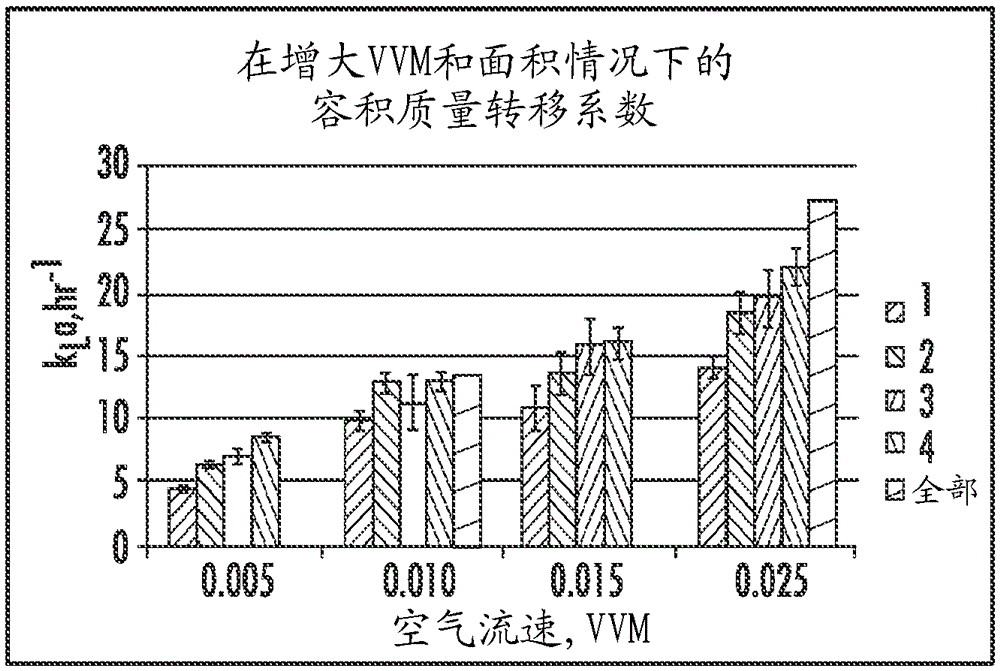

[0059] a series of k L a Tests were run in a 1000L vessel fitted with a 13" circular impeller, baffles, and appropriate transducers to establish a relationship between the area of gas permeable material in a modular sparger and the expected gas transfer efficiency. For these Test, impeller rpm at 60rpm, 10W / m 3 The power input remains constant. exist figure 1 All four positions of the modular sparger use Tyvek ? 1059B as gas permeable material and using air flow rates from 5lpm to 20lpm (from 0.005 to 0.020min -1 air velocity (vvm)), and run three replicates of each condition. A full size sparger was also tested. A simulated medium consisting of water, Pluronic (0.2%), 1XPBS and 50ppm antifoam was used. The results are shown in Figure 7 middle. Data indicate that higher air velocity results in higher k L a value.

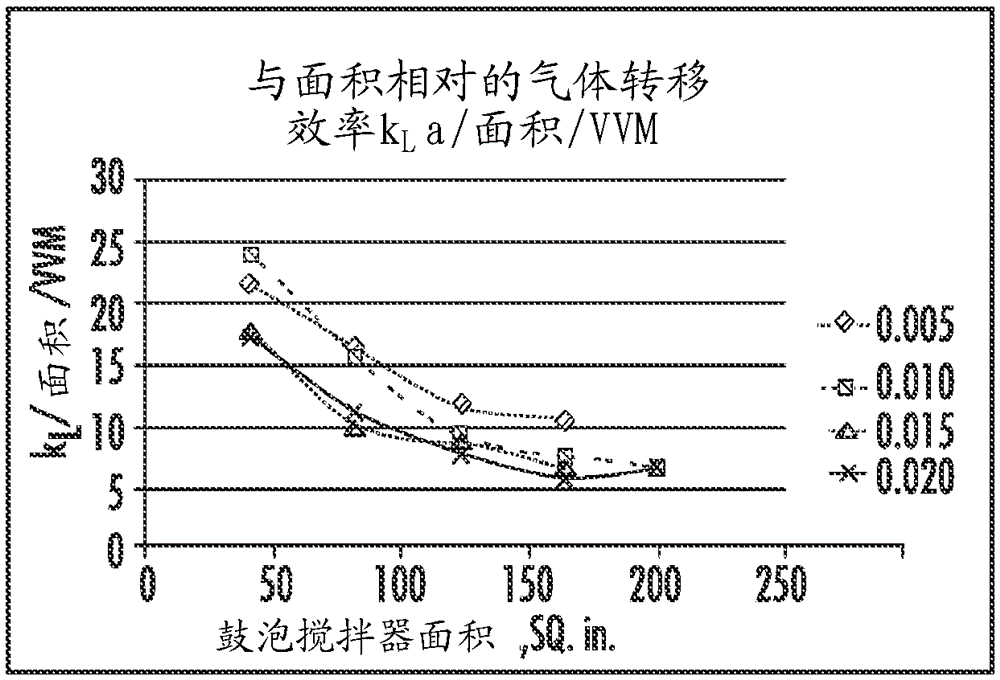

[0060] by adding k L a / area / vvm is compared to the area of each modular segment of the sparger to determine gas transfer efficiency. Figure 8 This...

example 2

[0064] Modular spargers according to embodiments disclosed herein allow for the use of more than one type of gas permeable material in the system. Example 1 demonstrates the achievable high-k L a value, where TYVEK ? The material occupies only two of the four modular segments of the sparger mixer. For example, the gas permeable material used for the remaining two modular segments may be chosen to produce ? Materials with larger air bubbles such as Porex ? POR97619 ("PE-10"), POR4920 ("PE-40"), and POR4903 ("PE-90"), all of which are made of polyethylene.

[0065] Using the vessel of Example 1, these three types of gas permeable materials were evaluated in one and two segments of the sparging mixer over a range of air flow rates from 5 lpm to 50 lpm (0.005 vvm to 0.05 vvm), with impeller rpm at held constant at 60 rpm. The results are summarized in the Figure 11 middle.

[0066] In general, larger pore size (PE-90) materials tend to give lower k L a value, however the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com