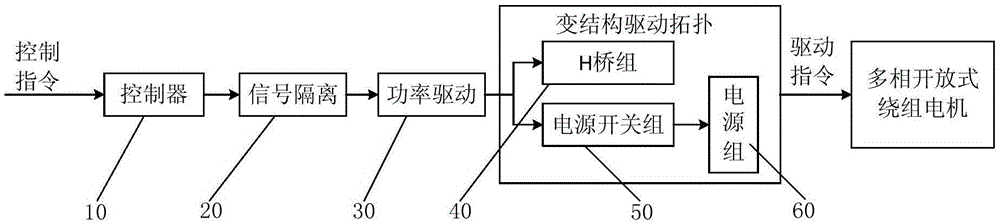

Variable structure driving topology

A variable structure and topology technology, which is applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of not being able to better meet the wide-range use requirements of the motor system, and being fixed, so as to save mechanical maintenance and reduce The effect of weight and volume, strong online structure change ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

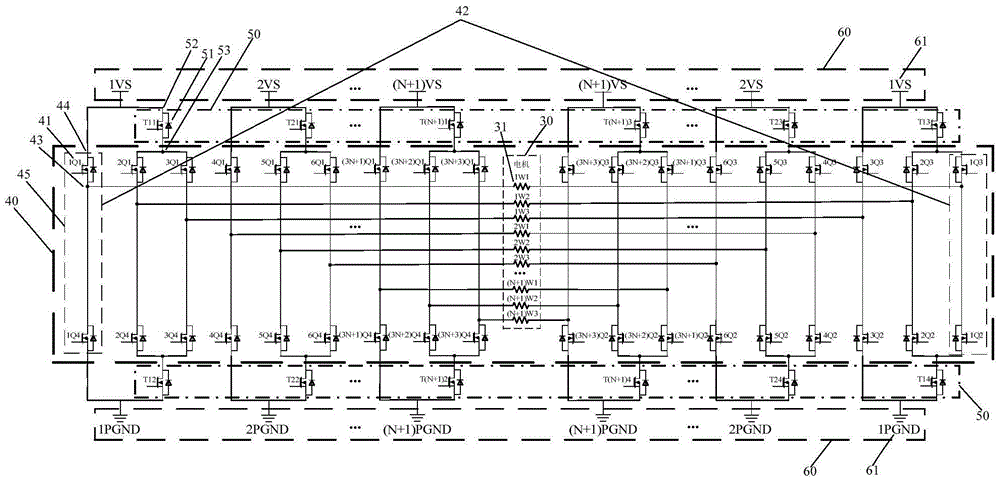

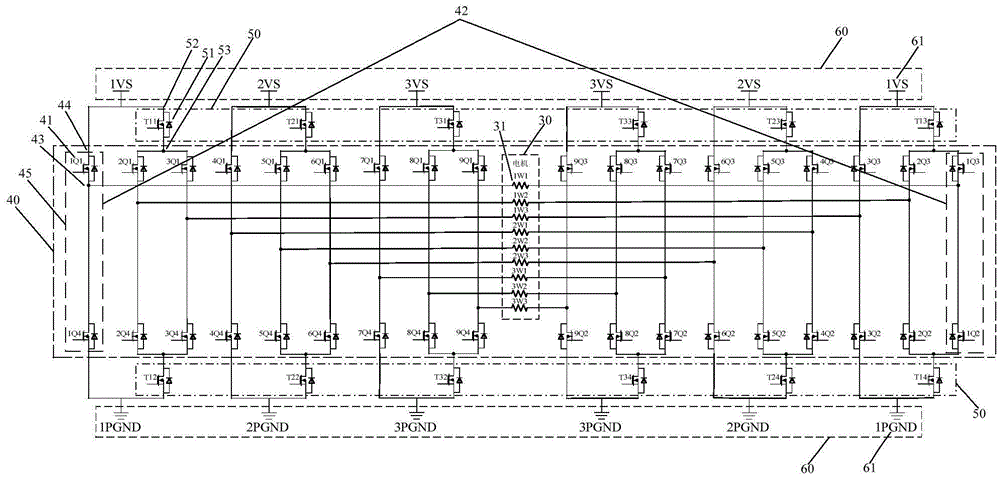

[0035] figure 2 As shown, the number of power tubes in the H-bridge group 40 matches the number of phases of the open-winding motor. When the number of phases of the open-winding motor is 9, where N=2, the number of power tubes 41 is 36, divided into 9 H bridge. The three H-bridges connected to the three-phase winding terminals of the open-winding motor form a group and are powered by the same DC power supply. For example, the three H-bridges connected to the windings 1W1, 1W2 and 1W3 share a DC power supply 1VS, which can Save the number of power supplies. Each H-bridge 42 comprises two bridge arms 45, left and right, and the bridge arm 45 is divided into left and right with an open winding motor as a boundary. Each bridge arm 45 comprises an upper and a lower power tube 41. 42 has four power tubes 41 in total, and a winding connection terminal 43 is provided at the middle point of each bridge arm 45, and the winding connection terminal 43 is respectively connected with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com