Method using nuclear magnetic resonance to measure rock porosity

A technology of rock porosity and nuclear magnetic resonance, which is used in the analysis, measurement device, material analysis by resonance, etc. of using nuclear magnetic resonance, which can solve the problems of inaccurate evaluation, easy water loss, and high evaluation of irreducible water and small pore water. Achieve the effect that is conducive to research and accurate porosity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Use a core drilling sampling machine model YZ-1 to drill the rock with dissolved pores into a column with a diameter of 2.5cm, and then use a rock cutter to cut the cylindrical rock into a core column with a length of 5cm . Using chloroform as the extraction solvent, the core column was subjected to Soxhlet extraction for 36 hours, and then the core column was dried at 100°C until the chloroform volatilized.

[0031](2) The dissolution pores of the core column include large-diameter dissolution pores and small-diameter dissolution pores. Use tweezers to insert cotton into the large-diameter dissolution pores of the core column, and insert 0.02 g of cotton into the large-diameter dissolution pores with a pore diameter of 4 mm. Insert 0.03g of cotton into the large-diameter dissolution hole with a diameter of 6mm; insert 0.06g of cotton into the large-diameter dissolution hole with a diameter of 8mm; insert 0.08g of cotton into the large-diameter dissolution hole with...

Embodiment 2

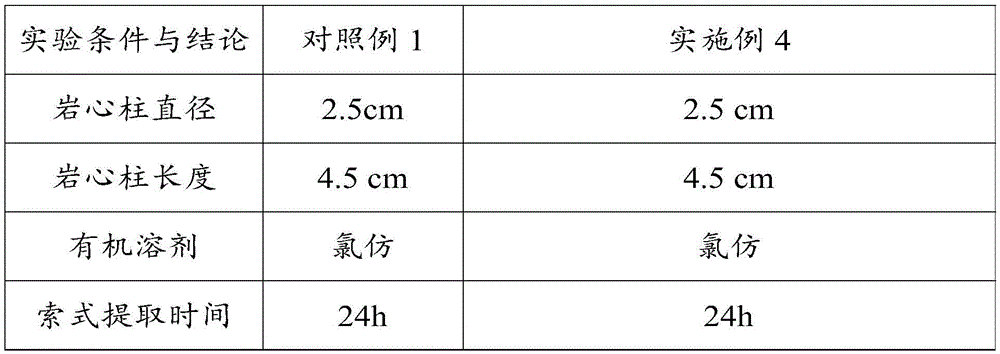

[0036] (1) Drill the rock with dissolution holes into a column with a diameter of 2.5cm using a core drilling sampling machine model YZ-1, and then use a rock cutter to cut the cylindrical rock into a core with a length of 4.5cm column. Using chloroform as the extraction solvent, the core column was subjected to Soxhlet extraction for 24 hours, and then the core column was dried at 105°C until the chloroform volatilized.

[0037] (2) The dissolution pores of the core column include large-diameter dissolution pores and small-diameter dissolution pores. Use tweezers to insert cotton into the large-diameter dissolution pores of the core column, and insert 0.005 g of cotton into the large-diameter dissolution pores with a pore diameter of 2 mm. Insert 0.02g of cotton into the large-diameter dissolution hole with a diameter of 4mm; insert 0.03g of cotton into the large-diameter dissolution hole with a diameter of 6mm; insert 0.06g of cotton into the large-diameter dissolution hole ...

Embodiment 3

[0042] (1) Use a core drilling and sampling machine model YZ-1 to drill the rock with dissolved pores into a column with a diameter of 2.5cm, and then use a rock cutter to cut the cylindrical rock into a core with a length of 4.7cm column. Using chloroform as the extraction solvent, the core column was subjected to Soxhlet extraction for 48 hours, and then the core column was dried at 102°C until the chloroform volatilized.

[0043] (2) The dissolution pores of the core column include large-diameter dissolution pores and small-diameter dissolution pores. Use tweezers to insert cotton into the large-diameter dissolution pores of the core column, and insert 0.01 g of cotton into the large-diameter dissolution pores with a pore diameter of 3 mm. Insert 0.02g of cotton into the large-diameter dissolution hole with a diameter of 5mm; insert 0.04g of cotton into the large-diameter dissolution hole with a diameter of 7mm; insert 0.07g of cotton into the large-diameter dissolution hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com