Mechanical equipment offline detection system vibration signal spectrum analysis and alarm method

A vibration signal and off-line detection technology, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the difficulty of monitoring frequency components and frequency band positioning, and cannot reasonably describe the distribution characteristics of spectral lines in the full frequency band, vibration signal spectrum Structural fluctuations and other problems, to achieve the effect of improving the automatic analysis ability and the accuracy of the alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

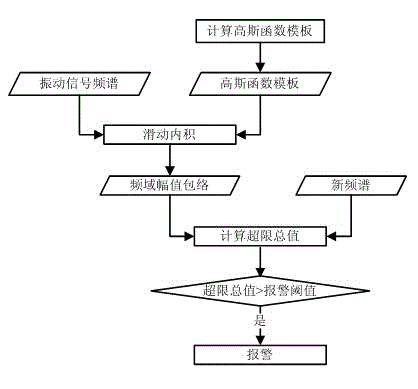

[0023] Example figure 1 As shown, this includes the following steps:

[0024] Step 1. Perform Fourier transform on the vibration signal to obtain the vibration amplitude sequence and frequency component sequence {A i , f i |i=0,Λ,N-1}, where A i is the vibration amplitude, f i is the frequency component, N is the number of spectral lines;

[0025] Step 2, adopt the frequency spectrum data of Gaussian function template smooth vibration signal, select positive odd number L greater than 3 as smoothing length, calculate the central position c=(L-1) / 2 of Gaussian function template, calculate the width coefficient of Gaussian function template Get the sequence of Gaussian functions j=0,Λ,L-1;

[0026] Step 3. Divide each element of the Gaussian function sequence by the central element G c , get Gaussian function template M j =G j / G c ,j=0,Λ,L-1;

[0027] Step 4: Extend c points before and after the vibration amplitude sequence to obtain an amplitude sequence of length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com