Directional static blasting construction method for foundation pit stratum and combined guiding device for directional static blasting construction method

A static blasting and construction method technology, applied in blasting, infrastructure engineering, excavation, etc., can solve the problems of difficult to determine the effect of blasting, unclear surface conditions, complex device structure, etc., to improve blasting efficiency, structure and structure. Simple processing and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

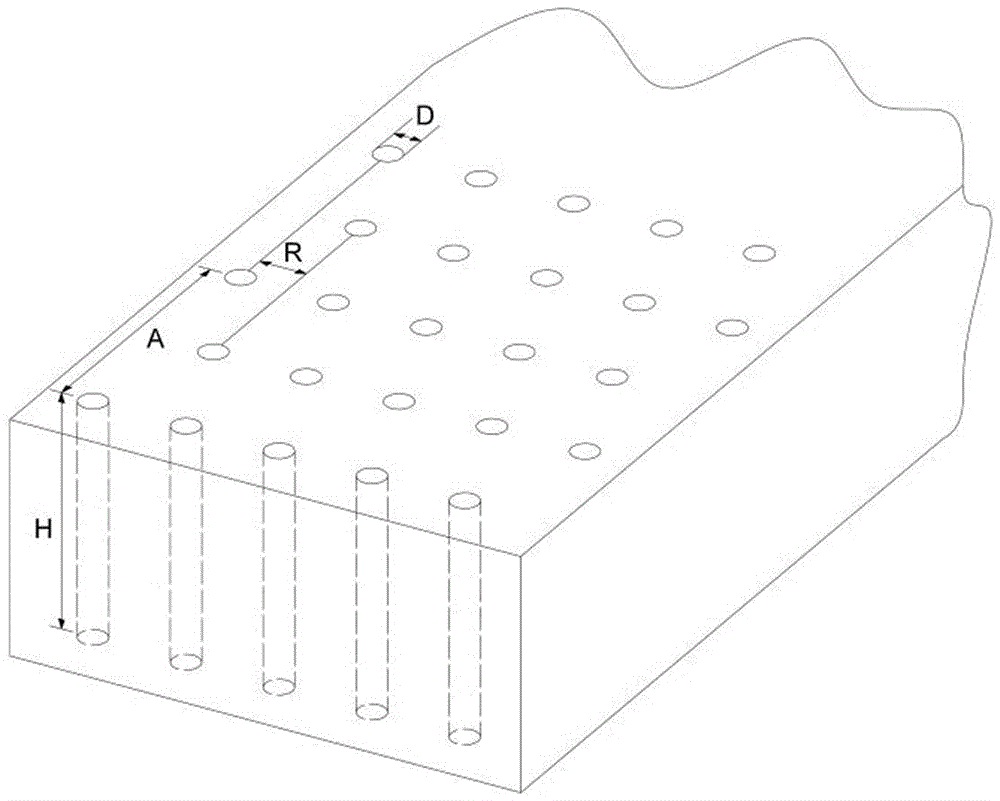

[0055] The present invention will be further described by taking the excavation construction of foundation pit rock layer in the space required for the installation of escalators in Aizhai Sightseeing Elevator Project as an example and in conjunction with the accompanying drawings.

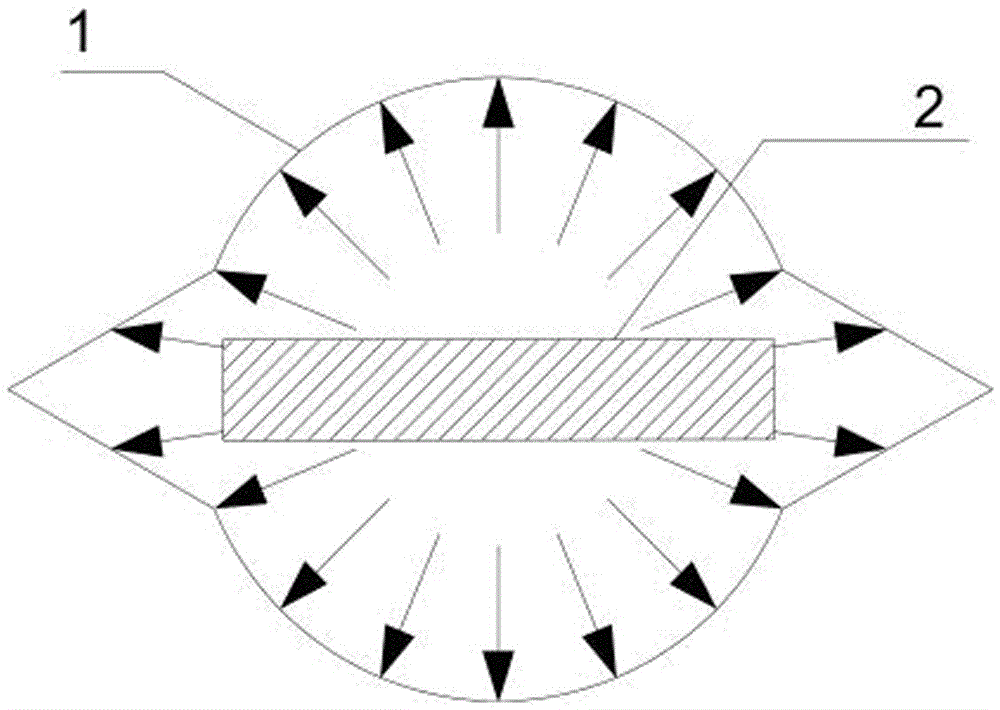

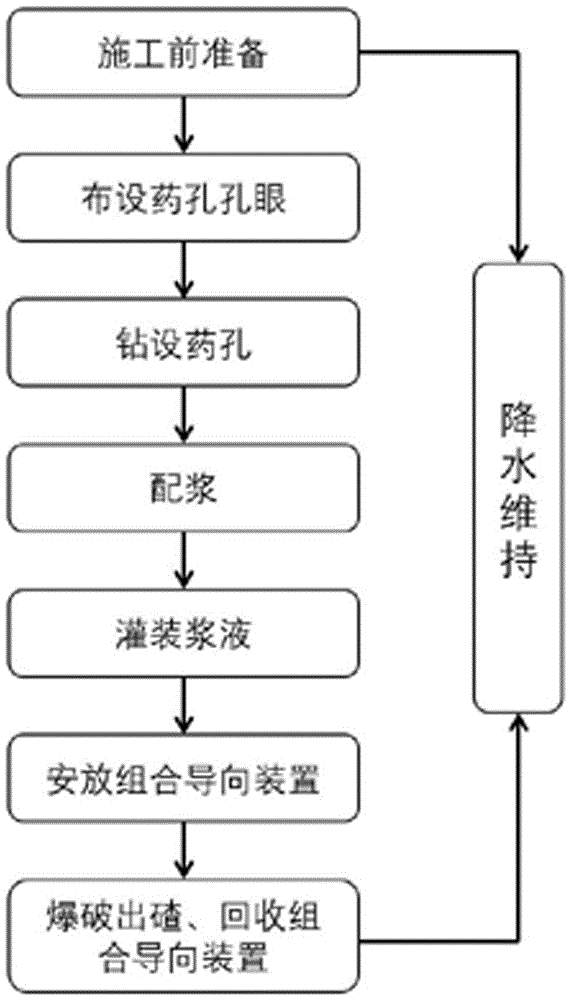

[0056] refer to figure 1 , the technological principle on which the present invention is based is as follows:

[0057] (1) The main component of the silent crushing agent (HSCA) is CaO, which generates Ca(OH) after mixing with water 2 , in the free state, Ca(OH) 2 The volume expansion is about 3 times that of CaO, and the porosity also increases accordingly, no expansion pressure is generated, only the volume expands; but in the state where the expansion space is limited, Ca(OH) 2 When the volume increases, they squeeze each other, and the porosity becomes smaller, resulting in expansion pressure, and this solid expansion becomes the driving force for breaking rocks.

[0058] (2) In the drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com