Hole pressure sealing device for coal mine drill hole and use method of device

A hole-sealing device and hole-pressing technology, which is applied in earth-moving drilling, sealing/isolation, wellbore/well components, etc., can solve the problem of increasing the gas gushing volume and gas content in the goaf, and the deformation of the cement slurry sealing section. Breaking, affecting the sealing effect, etc., to improve the sealing effect, reduce the amount of polyurethane, and ensure the effect of safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

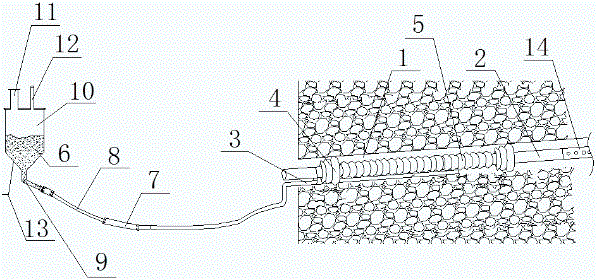

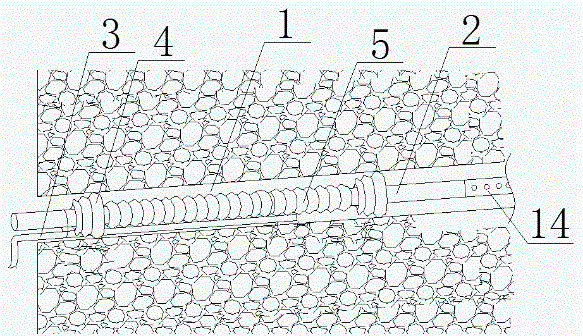

[0037] figure 1 and figure 2Show a specific embodiment of a pressure sealing device for coal mine drilling according to the present invention: the pressure sealing device for coal mine drilling includes a sealing device body with one end extending into the borehole 1, and the sealing device body includes a sealing iron Pipe 2, the side wall of the sealing iron pipe 2 is sleeved with a binding part, and the end of the binding part far away from the drill hole 1 is bound with a grouting pipe 3, and the binding part includes a fixed sponge bound at both ends of the side wall of the sealing iron pipe 2 14, between the fixed sponges 4 at both ends, there is a fixed sponge 2 5 bundled in the middle of the side wall of the sealing iron pipe 2, and the fixed sponge 4 at the end far away from the borehole 1 is bundled with a grouting pipe 3, through which the fixed sponge 1 4 and fixing sponge 2 5 can wrap a part of the side wall of the sealing iron pipe 2, reducing the gap, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com