Tri-linear shape in-plane bending yielding type energy dissipater and manufacturing method therefor

A manufacturing method and a surface technology, applied in building structures, building components, earthquake-proof, etc., can solve problems such as stress concentration, affecting plastic deformation ability and low-cycle fatigue performance, and achieve excellent energy consumption performance, good economic performance, The effect of improving low cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The in-plane bending yield type energy dissipator with a three-fold line shape and its manufacturing method proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use inaccurate scales, which are only used to facilitate and clearly illustrate the purpose of implementing the present invention.

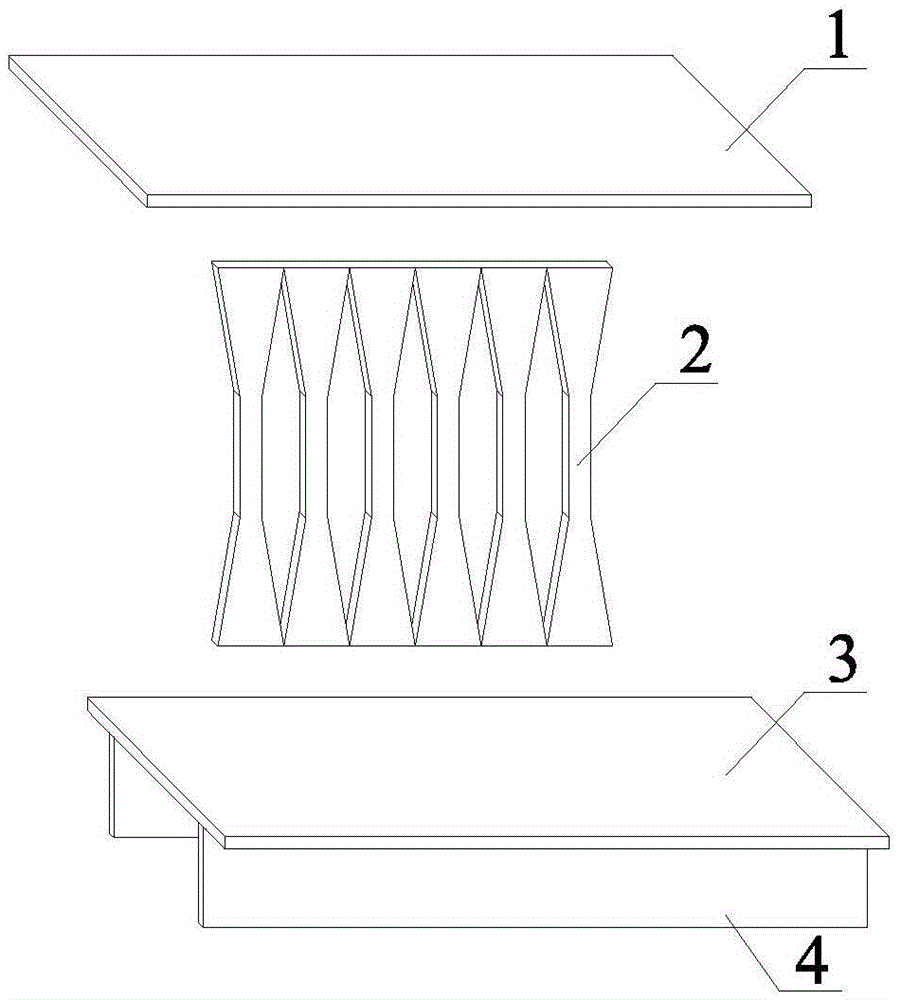

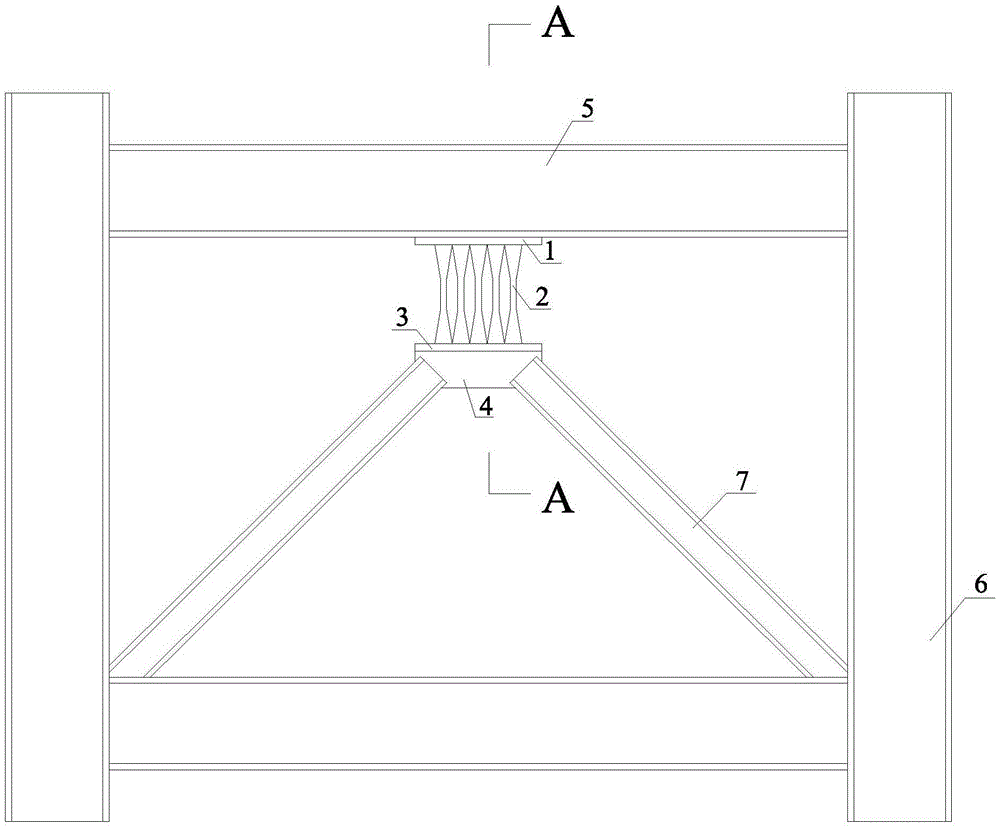

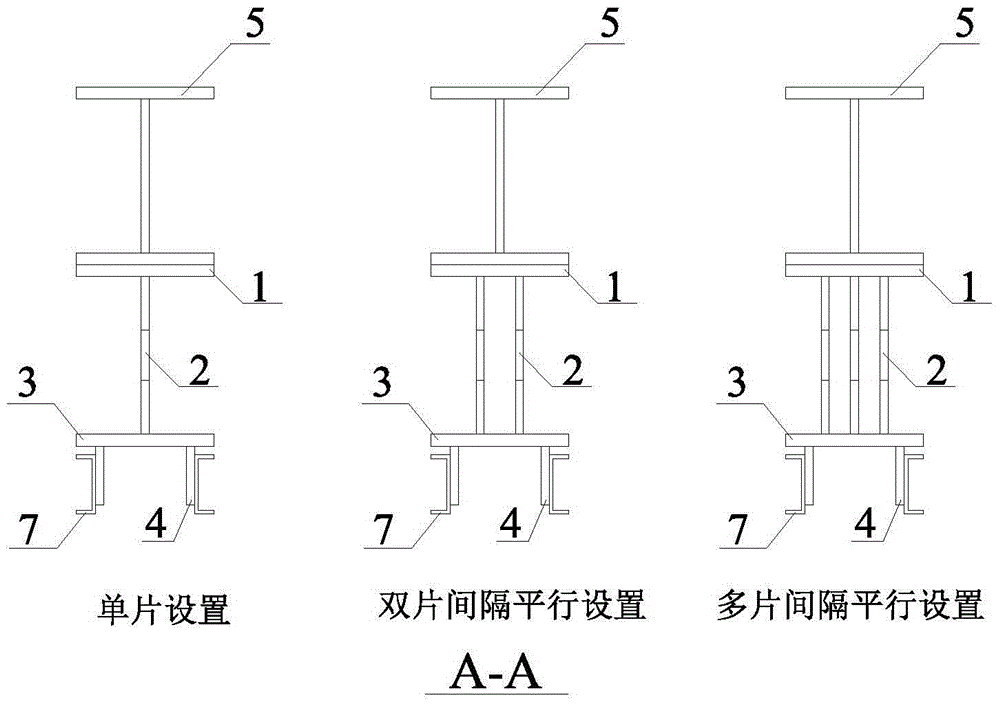

[0033] Such as Figure 1-4 As shown, a three-fold line shape in-plane bending yield type energy dissipator provided by the present invention includes a top plate 1, an energy-dissipating steel plate 2, a bottom plate 3 and a connecting plate 4, and the energy-dissipating steel plate 2 is arranged on the top plate 1 and the bottom plate 3, which are respectively vertically connected between the lower bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com