Preparation method of light-heat sensitive quick response plural gel

A fast-response, composite gel technology, applied in the field of hydrogel preparation, can solve the problems of poor mechanical properties of gel, slow response speed, limited application of light-responsive gel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a light- and heat-sensitive fast-response composite gel, the process of which is as follows:

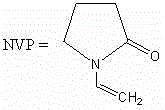

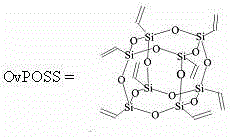

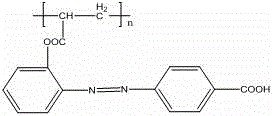

[0042] (1) Co-dissolve the photosensitive monomer, N-vinylpyrrolidone, POSS cross-linking agent OvPOSS, and organic cross-linking agent BIS in tetrahydrofuran and place in a container. Stir in a water bath at 50°C for 30 minutes under nitrogen protection until uniform Transparent, after rising to 60°C and adding initiator AIBN, stirring for 10 minutes, sealing, reacting at 60°C for 24 hours, taking out the gel, and repeatedly washing with tetrahydrofuran and water to remove unreacted monomers, to obtain The first network gel A;

[0043] Wherein, the quality of the photosensitive monomer is 6.5% of the quality of tetrahydrofuran, the quality of N-vinylpyrrolidone is 5.3% of the quality of tetrahydrofuran, and the quality of the POSS crosslinking agent OvPOSS is 12.6% of the sum of the quality of the photosensitive monomer and N-vinylpyrrolidone, The qual...

Embodiment 2

[0052] A method for preparing a light- and heat-sensitive fast-response composite gel, the process of which is as follows:

[0053] (1) Co-dissolve the photosensitive monomer, N-vinylpyrrolidone, POSS cross-linking agent OvPOSS, and organic cross-linking agent BIS in tetrahydrofuran and place in a container. Stir in a water bath at 50°C for 30 minutes under nitrogen protection until uniform Transparent, after rising to 60°C and adding initiator AIBN, stirring for 10 minutes, sealing, reacting at 60°C for 24 hours, taking out the gel, and repeatedly washing with tetrahydrofuran and water to remove unreacted monomers, to obtain The first network gel A;

[0054] Wherein, the quality of the photosensitive monomer is 7.3% of the quality of tetrahydrofuran, the quality of N-vinylpyrrolidone is 5.3% of the quality of tetrahydrofuran, and the quality of the POSS crosslinking agent OvPOSS is 15.7% of the sum of the quality of the photosensitive monomer and N-vinylpyrrolidone, The qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com