Carbon-based auxiliary, preparation method thereof and application in livestock manure composting

A technology of livestock manure and base auxiliary materials, which is applied in the field of solid waste recycling, can solve the problems of easy anaerobic acidification, difficult recycling, low mass transfer efficiency, etc., and achieves obvious deodorization effect, simple operation process and adsorption. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of carbon-based auxiliary material and preparation method thereof

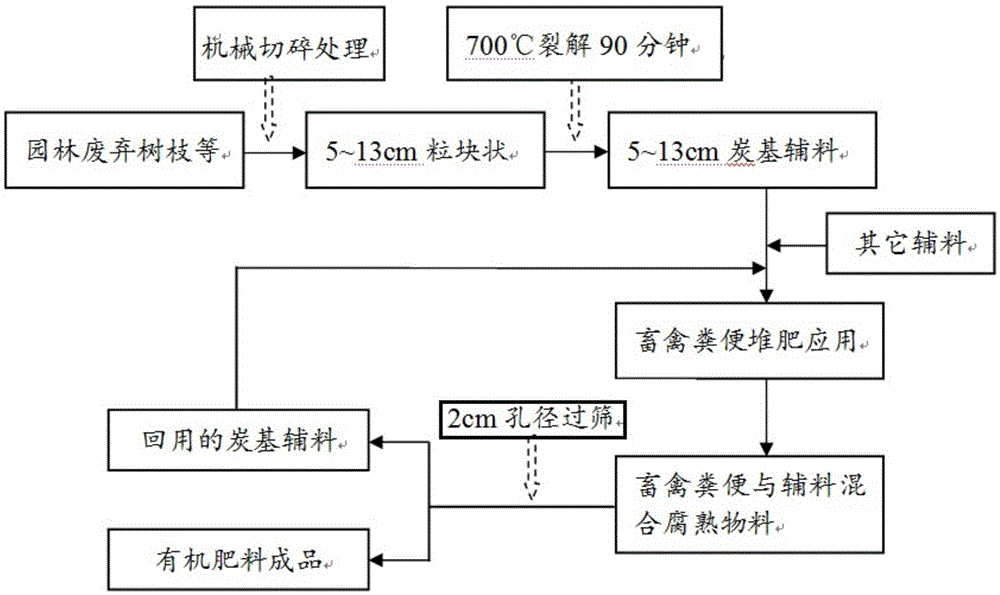

[0039] The pruned branches and discarded tree trunks are processed into 5-13cm granular biomass materials with a mechanical cutting machine, and then the granular biomass materials are placed in a cracking furnace. The cracking time is 90 minutes, then cooled and set aside to obtain the carbon-based auxiliary material.

Embodiment 2

[0040] Embodiment 2: the application of a kind of carbon-based auxiliary material in poultry manure composting

[0041] composting process by figure 1 As shown in the operation, according to the volume ratio of 1:0.33:0.67, the livestock and poultry manure, mushroom residue, and the carbon-based auxiliary materials of Example 1 are mixed in sequence. The moisture content of the mixed material is 65%, and the carbon-to-nitrogen ratio on a dry basis is controlled at about 18. , the mixed material is subjected to high-temperature aerobic fermentation in the organic fertilizer production workshop. The composting process includes a heating-up stage, a high-temperature stage, and a cooling stage. Turn the compost when the temperature is higher than 75°C, or once every 7-10 days; after 28-35 days of fermentation, use a sieve with a pore size of 2 cm to screen the carbon-based auxiliary materials from the compost mixture and monitor the temperature of the composting process And the d...

Embodiment 3

[0042] Embodiment 3: the application of a kind of carbon-based auxiliary material in poultry manure composting

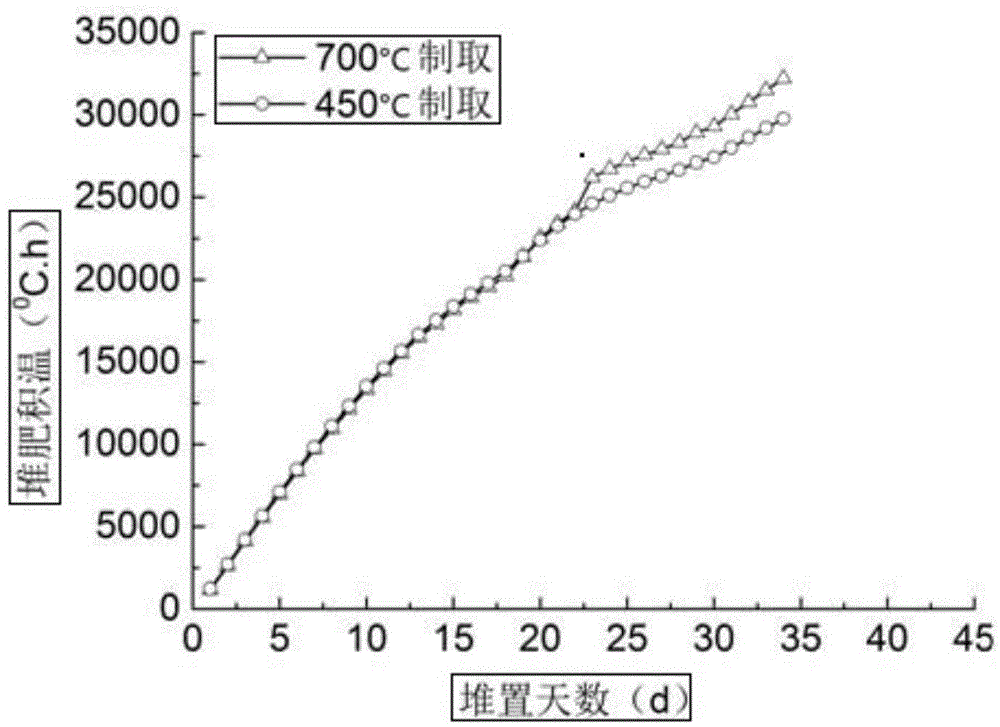

[0043] composting process by figure 1 According to the operation shown, according to the volume ratio of 1:0.4:0.6, the livestock and poultry manure, mushroom residue, and the carbon-based auxiliary materials of Example 1 are mixed successively. The moisture content of the mixed material is controlled at 70%, and the carbon-nitrogen ratio on a dry basis is controlled at 19. At the same time, the volume ratio of livestock and poultry manure, mushroom residue, and carbon-based auxiliary materials is 1:0.7:0.3 and 1:0.1:0.9 as a control. The rest of the operating steps were the same as in Example 2, and the whole test was repeated 3 times. Figure 4 The results are remarkable. When carbon-based auxiliary materials replace 90% of conventional auxiliary materials, the heating effect on the composting process is not as good as that of 30% and 60% treatments, and the warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com