EPS (expandable polystyrene) improved soil for treating expansive soil slopes and construction method thereof

A construction method and technology of expansive soil, applied in the field of geotechnical engineering, can solve problems such as reducing the sliding force of the slope, and achieve the effects of reducing the load of the slope, reducing the expansion and contraction, reducing the free expansion rate and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

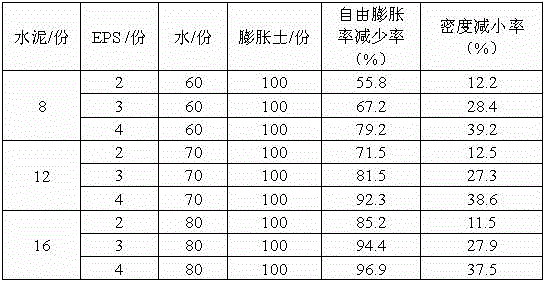

[0032] A kind of EPS improved soil for treating expansive soil slopes. Put the excavated expansive soil, water and cement into a stabilized soil mixer for full mixing and mixing to form a uniformly flowing slurry; add EPS foam particles to the well-mixed In the slurry, continue to stir evenly to obtain EPS improved expansive soil; the particle size of EPS foam particles used in this embodiment is 1-5mm, and the particle packing density is 0.01-0.02g / cm 3 , the pure particle density is 0.02-0.03g / cm 3 . The EPS polystyrene foam particles are pre-expanded polystyrene foam particles.

[0033] The test ratio and the reduction rate of free expansion rate and density reduction rate of expansive soil improved by EPS are shown in Table 1 (Note: The reduction rate of free expansion rate and density reduction rate refer to the corresponding free expansion rate compared with untreated expansive soil rate and percentage of density reduction). It can be seen from the table that EPS impr...

Embodiment 2

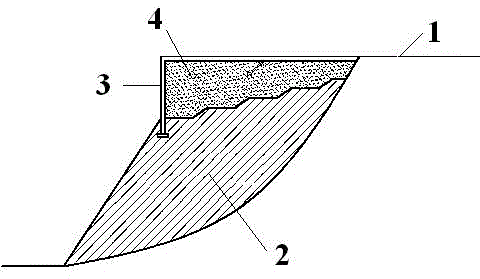

[0037] In this embodiment, the expansive soil is the expansive soil excavated from the side slope; the cement is Portland cement with a strength of 42.5MPa; the EPS foam particles are pre-expanded polystyrene foam particles, and the particle size is 1-5mm, particle packing density is 0.01-0.02g / cm 3 , the pure particle density is 0.02-0.03g / cm 3 .

[0038] Construction machinery includes a PC200 excavator and a 300t / h continuous stabilized soil mixer.

[0039] The EPS improved soil for expansive soil slope is formed by mixing polystyrene foam particles, expansive soil, cement and water in proportion, wherein the mass percentages of polystyrene foam particles, cement and water and expansive soil are respectively 2%, 8%, 60% (that is, 2 parts of polystyrene foam particles, 8 parts of cement, 60 parts of water, and 100 parts of expansive soil).

[0040] The construction method is as follows:

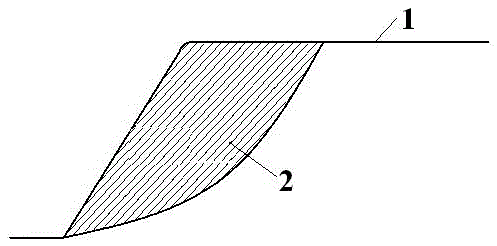

[0041] Press with an excavator figure 2 The expansive soil is excavated step by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com