A material handling method

A treatment method and material technology, applied in special treatment targets, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as low drying efficiency, poor drying effect, complex structure, etc., and achieve simple mechanism, The effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

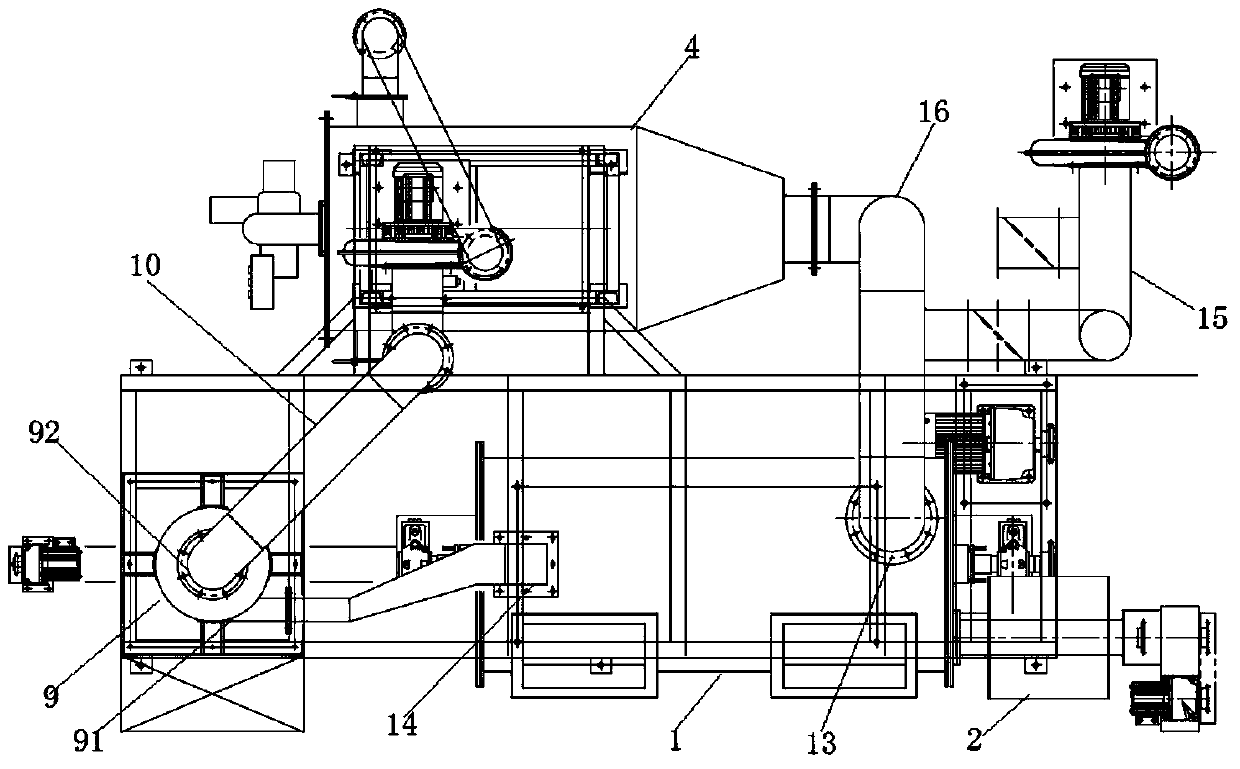

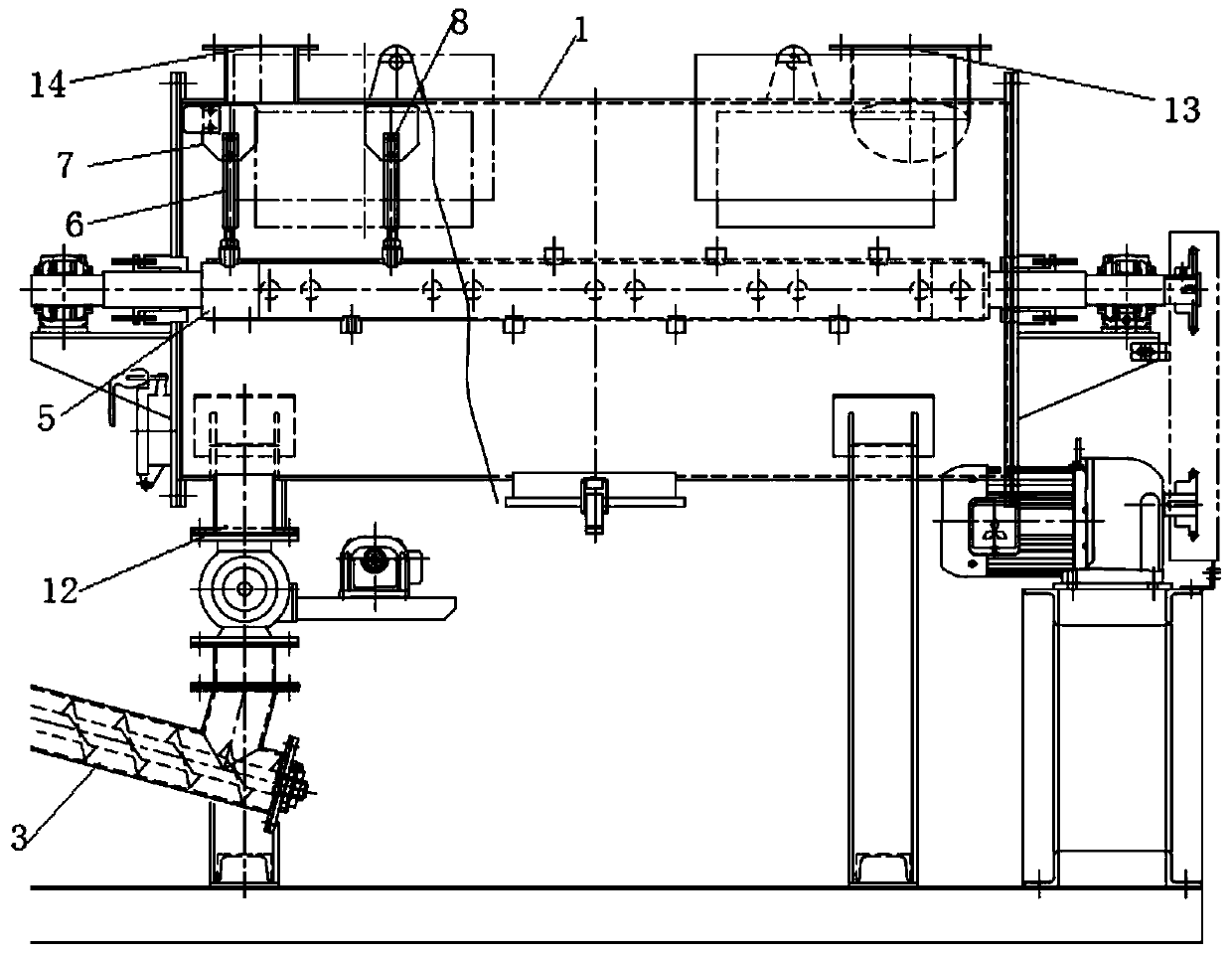

[0048] like figure 1 , this embodiment provides a material handling system comprising

[0049] The furnace body 1 is arranged along the horizontal direction, and has a cavity, a material inlet 11 for feeding and taking out materials, and a material outlet 12; and a first air inlet 13 and a first air outlet 14 for heating gas to flow in and out;

[0050] Feeding device 2, used for adding materials into the furnace body 1;

[0051] The material receiving device 3 is used to collect the dried material in the furnace body 1;

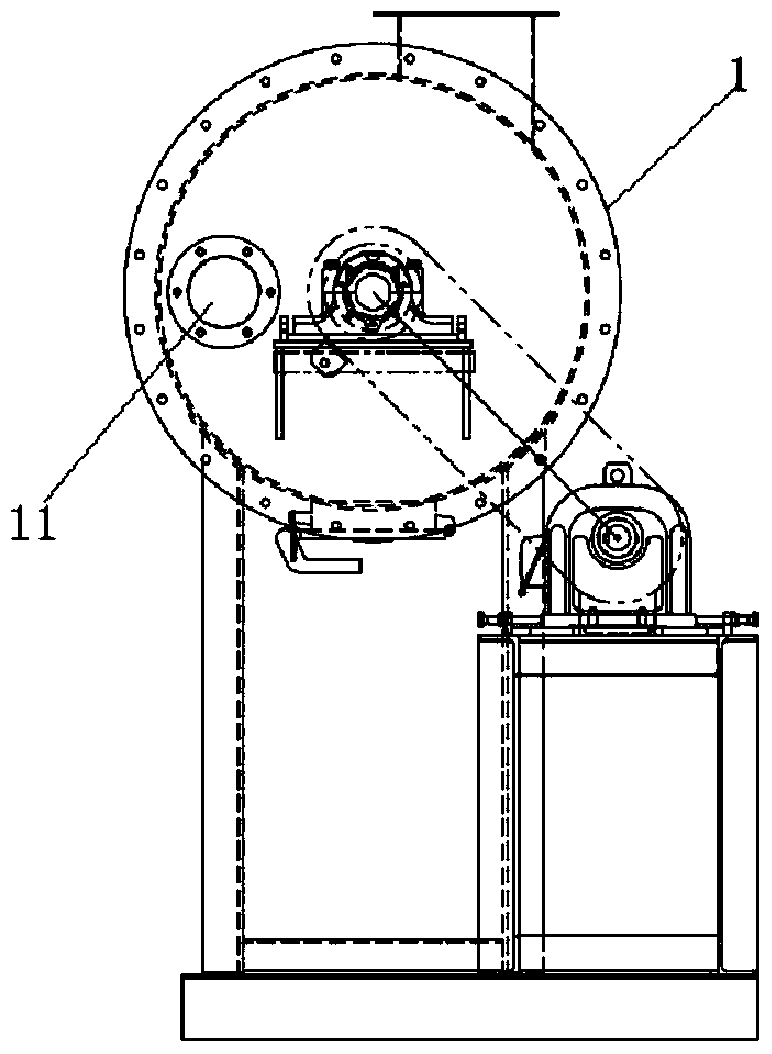

[0052] The first rotating shaft 17 is installed in the cavity of the furnace body 1, and has an installation cavity. Several heating wires 19 are arranged on the inner wall of the installation cavity. The heating wires generate heat when they are energized. Made of thermally conductive material; such as Figure 4 shown;

[0053] The second rotating shaft 5 is sleeved on the first rotating shaft, and forms a ventilation cavity with the first rotating shaf...

Embodiment 2

[0084] This embodiment provides a material processing method, including the following steps

[0085] the step of heating the material;

[0086] The step of stirring the material;

[0087] the step of drying the material;

[0088] The heating step, the stirring step and the drying step are carried out simultaneously by using the same system, and the system is the material handling system described in Example 1.

[0089] Since the material handling system described in Embodiment 1 is used, the material handling method has any of the advantages described above.

[0090] The material treatment method is especially suitable for the treatment of sludge materials, and can be used to bond each other during the drying of the materials through a good stirring effect, so as to improve the final drying effect of the materials.

[0091] As a preferred embodiment, the caliber of the air injection port is not greater than 3mm, and the air injection speed at the air injection port is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com