A circulating drying device

A technology of circulating drying and stirring device, which is applied in the drying of solid materials, dehydration/drying/concentrated sludge treatment, drying, etc., can solve the problems of poor drying effect and low drying efficiency, and achieve the improvement effect and uniform effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

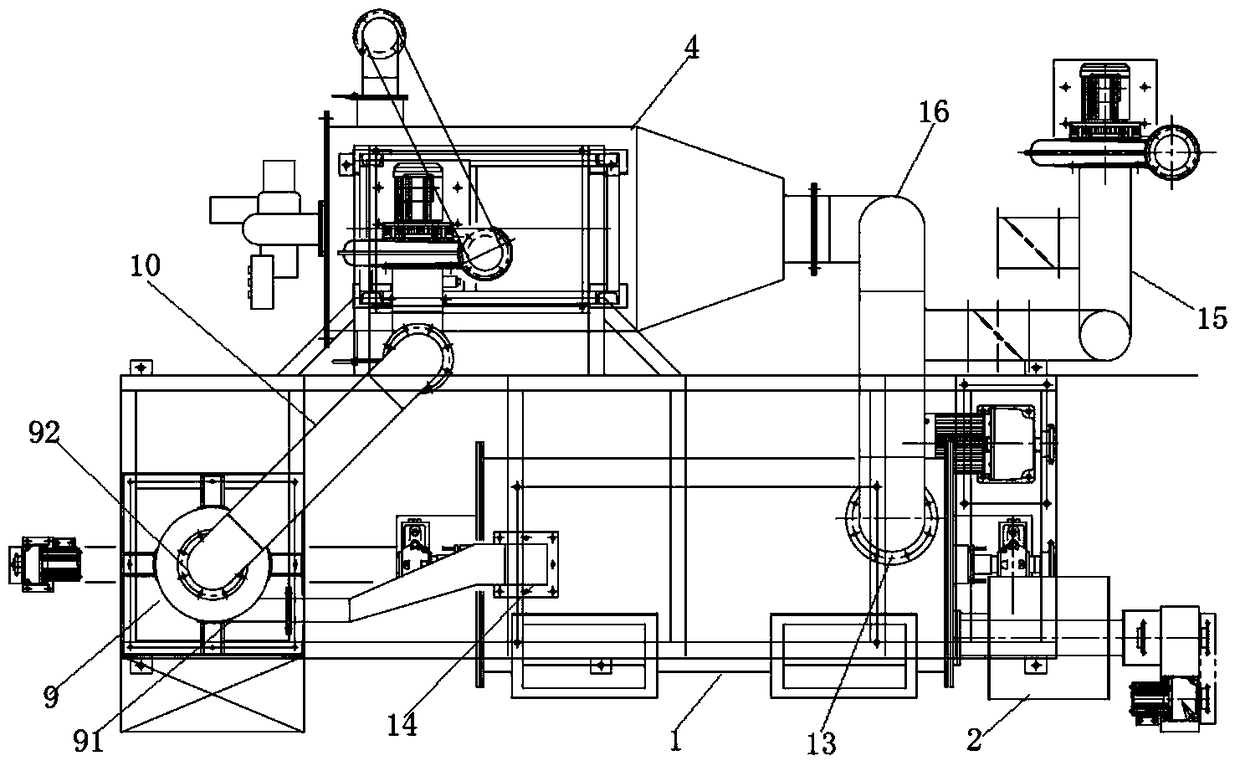

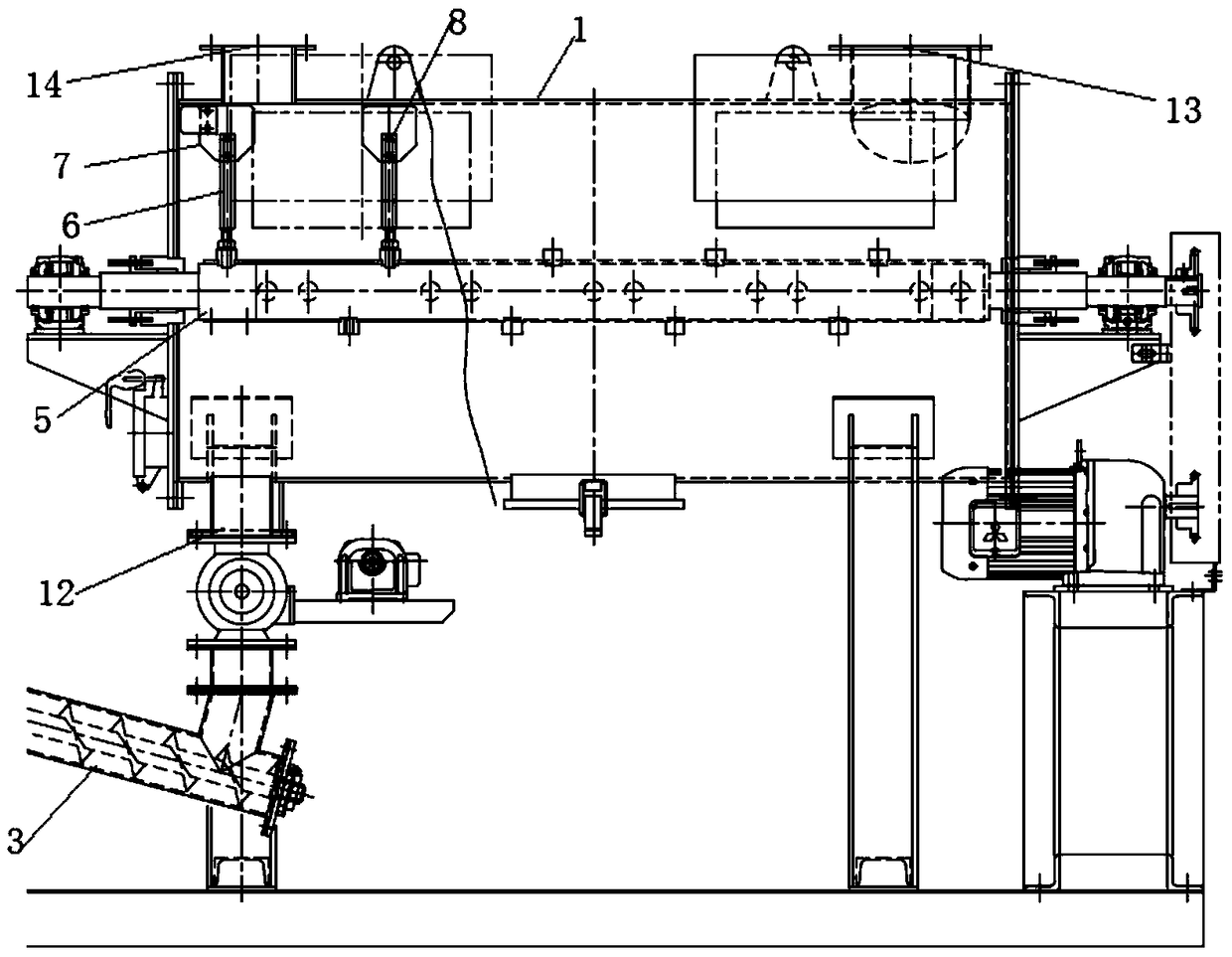

[0039] like figure 1 , the present embodiment provides a drying system, comprising

[0040] The furnace body 1 is arranged along the horizontal direction, and has a cavity, a material inlet 11 for feeding and taking out materials, and a material outlet 12; and a first air inlet 13 and a first air outlet 14 for heating gas to flow in and out;

[0041] Feeding device 2, used for adding materials into the furnace body 1;

[0042] The material receiving device 3 is used to collect the dried material in the furnace body 1;

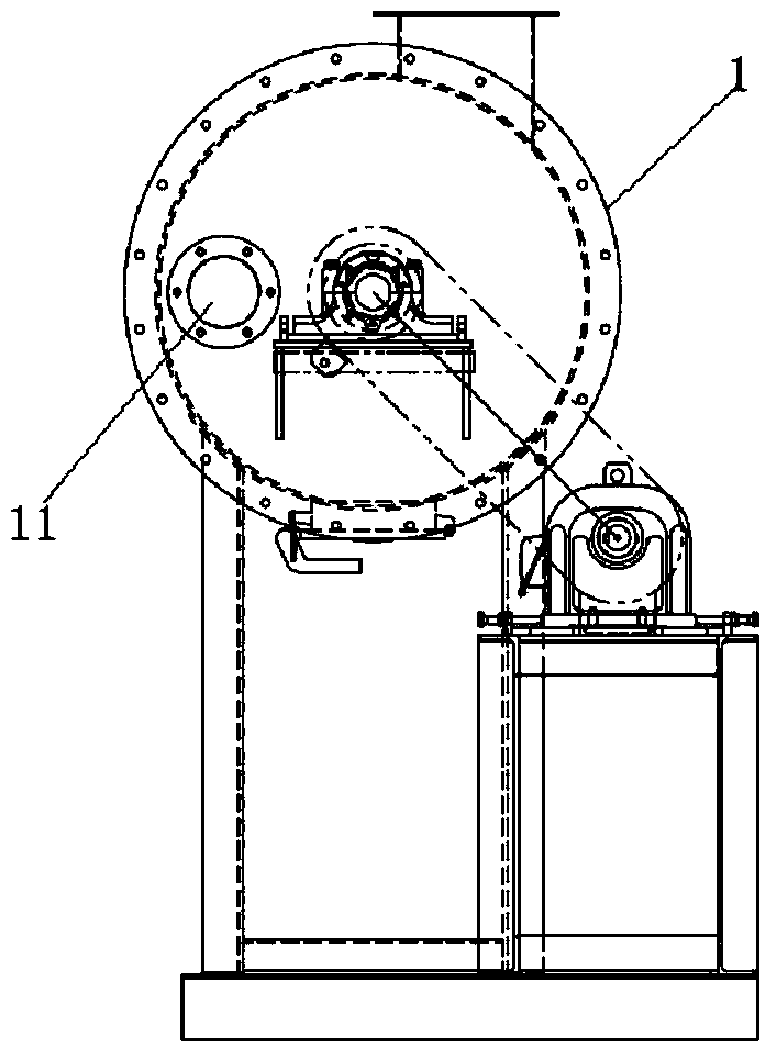

[0043] stirring device, including

[0044] The rotating shaft 5 is installed in the cavity of the body of furnace 1, the rotating shaft 5 has a ventilation chamber, and several gas injection ports are arranged on the ventilation cavity, and the direction of the gas injection of the gas injection ports is the same as that of the stirring shaft 6. The stirring direction and the stirring direction of the blades 7 do not overlap and are not parallel, the air injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com