A kind of preparation method of screw rotor cbn electroforming grinding wheel

A technology of electroforming and rotor, applied in the direction of electroforming, electrolysis process, electrolysis components, etc., can solve the problems of difficult processing, low processing efficiency, unknown preparation method, etc., and achieve the goal of increasing surface activity, thorough treatment and strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

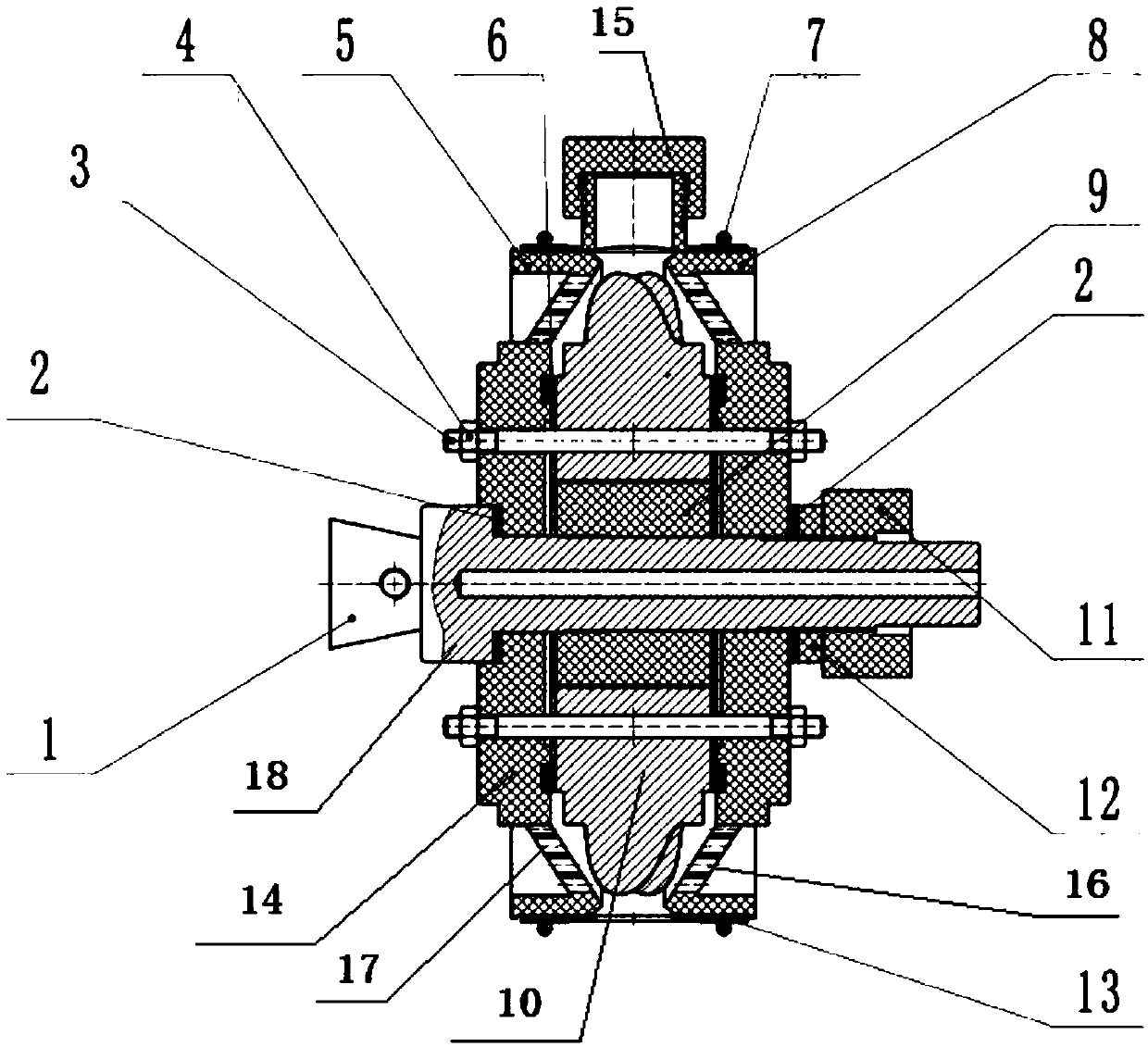

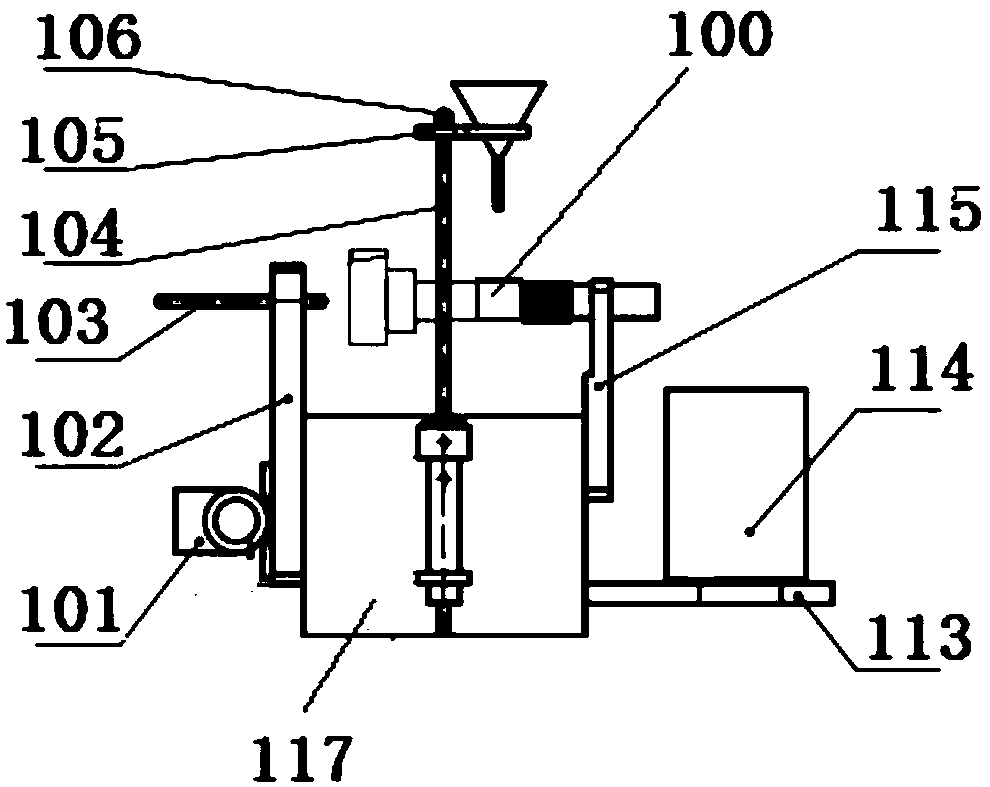

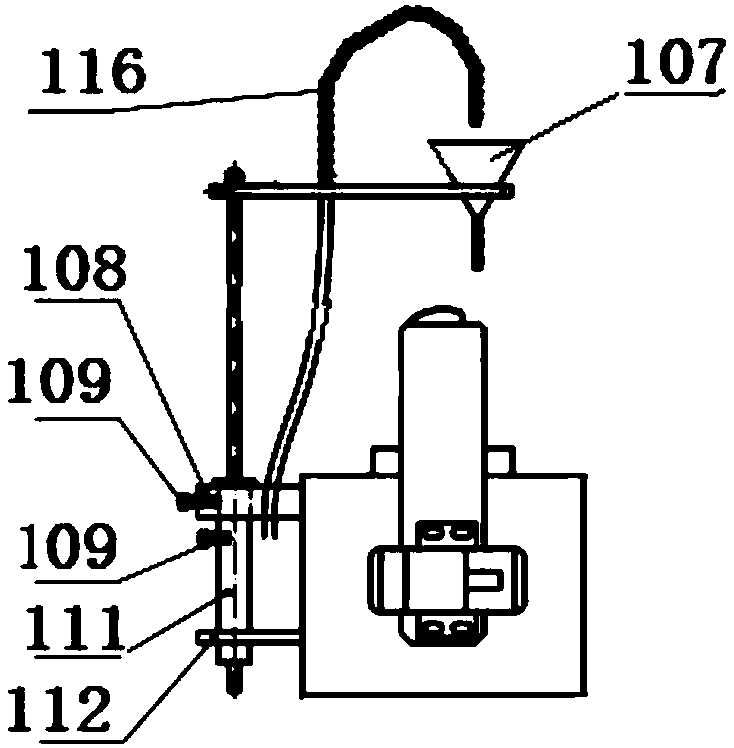

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below in conjunction with accompanying drawing, and the present invention comprises the following steps:

[0023] 1. Pre-treatment of CBN abrasives: Put CBN abrasives in a container, add strong alkali detergent 0.4 times the weight of CBN abrasives, heat and boil for 1 hour, wash with water until neutral, then add strong acid detergent 1.8 times the weight of CBN abrasives, heat and boil After 1 hour, wash with water until neutral;

[0024] The strong alkaline detergent is potassium hydroxide by weight: sodium hydroxide: deionized water is a mixture of 2:1:10;

[0025] Described strong acid detergent is the concentrated nitric acid by weight: the concentrated sulfuric acid: perchloric acid is the mixture of the concentrated nitric acid of 50:100:1, the concentrated sulfuric acid and perchloric acid;

[0026] In this embodiment, the addition amount of strong alkali detergent can also be 0.5 times, 0.55 times, 0.6 times etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com