An automatic grinding device

A grinding device, automatic technology, used in grinding drives, grinding machines, abrasives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

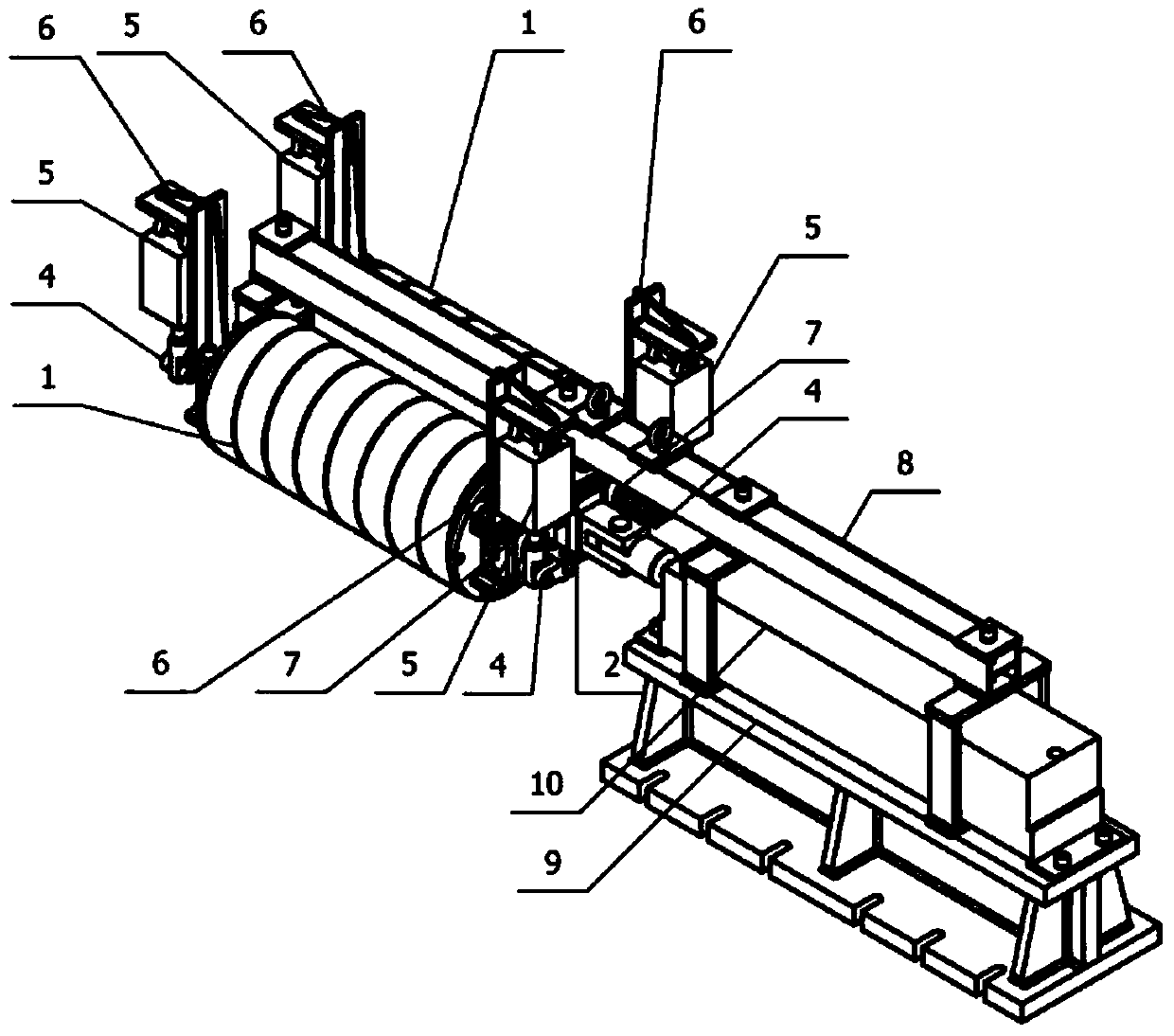

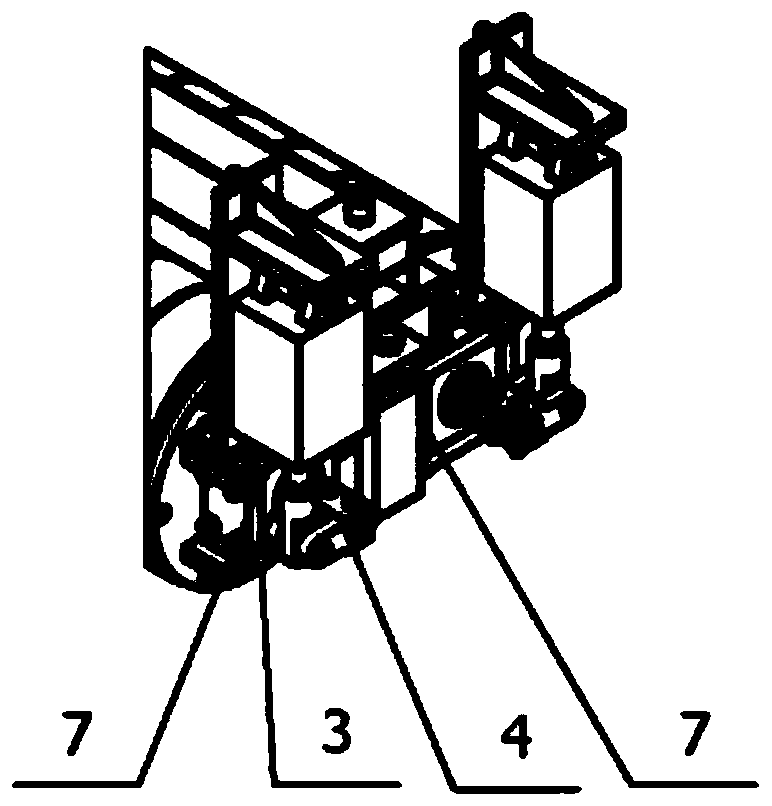

[0030] The automatic grinding device of the present invention comprises two grinding bodies 1 parallel to each other, a front frame 2, a rear frame 3, four bearing seat devices 7, four supports 6, four rotary mechanisms 4, four rotating grinding cylinders 5, a lifting Device 8, linear grinding cylinder 10, horn 9.

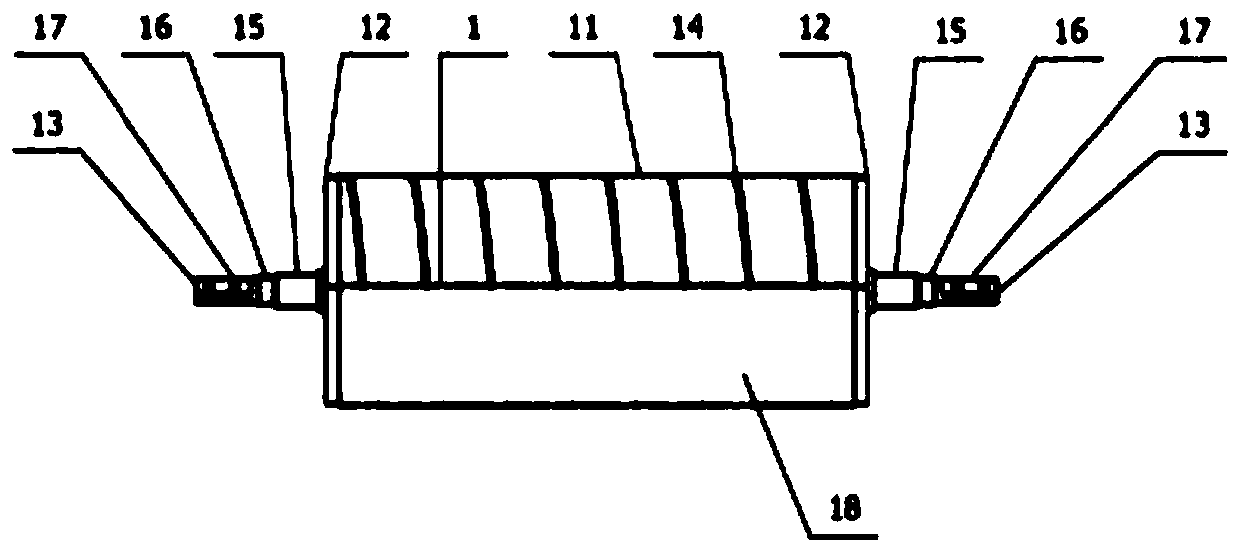

[0031] Such as image 3 As shown, two grinding bodies 1 are arranged parallel to each other, and each grinding body is a welding assembly, which is a grinding cutting tool, including a rotating shaft 13, a grinding rod 11 and two cover plates 12, wherein the two cover plates 12 are along the center Welded on the rotating shaft 13 line symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com