Graphene oxide/chitosan porous composite microspheres and preparation method as well as application thereof

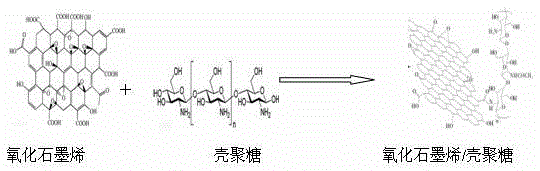

A technology of porous composite microspheres and chitosan, applied in the application and preparation of anionic dyes, the field of graphene oxide/chitosan porous composite microspheres, can solve the limitations of chitosan material application and chitosan mechanical strength Low, prone to breakage and other problems, to achieve the effect of reducing the preparation process time, facilitating storage and transportation, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

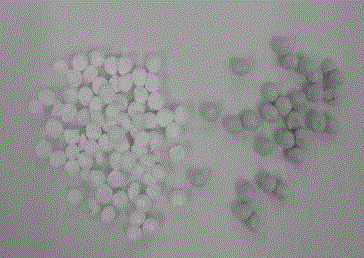

[0040] A preparation method of graphene oxide / chitosan porous composite microspheres, specifically comprising the steps of:

[0041] 1) Add chitosan to the acetic acid solution, stir and mix for 2 hours, then add graphene oxide-water mixed solution, stir and mix in a water bath at 55°C for 1 hour to obtain a graphene oxide / chitosan mixed solution; graphene oxide / chitosan In the sugar mixed solution, the mass fraction of acetic acid is 1%, the concentration of chitosan is 1.0wt%, the quality of acetic acid and chitosan is 1g, and the graphene oxide-water mixed solution of 1mg / mL is 0.5ml;

[0042] 2) Inhale the obtained graphene oxide / chitosan mixed solution into a syringe, drop it into a 3.0wt% NaOH solution at an injection speed of 1ml / min, solidify for 12h, and wash it with deionized water until neutral;

[0043] 3) Pre-freezing with liquid nitrogen, and then vacuum-drying in a freeze dryer at -53°C for 12 hours to obtain porous microspheres with a particle size of 3-4 mm wi...

Embodiment 2

[0045] A preparation method of graphene oxide / chitosan porous composite microspheres, specifically comprising the steps of:

[0046] 1) Add chitosan to the acetic acid solution, stir and mix for 2 hours, then add graphene oxide-water mixed solution, stir and mix in a water bath at 55°C for 1 hour to obtain a graphene oxide / chitosan mixed solution; graphene oxide / chitosan In the sugar mixed solution, the mass fraction of acetic acid is 1%, the concentration of chitosan is 1.0wt%, the quality of acetic acid and chitosan is 1g, and the graphene oxide-water mixed solution of 1mg / mL is 1ml;

[0047] 2) Inhale the obtained graphene oxide / chitosan mixed solution into a syringe, drop it into a 3.0wt% NaOH solution at an injection speed of 1ml / min, solidify for 12h, and wash it with deionized water until neutral;

[0048] 3) Pre-freezing with liquid nitrogen, and then vacuum-drying in a freeze dryer at -53°C for 12 hours to obtain porous microspheres with a particle size of 3-4 mm with a...

Embodiment 3

[0050] A preparation method of graphene oxide / chitosan porous composite microspheres, specifically comprising the steps of:

[0051] 1) Add chitosan to the acetic acid solution, stir and mix for 2 hours, then add graphene oxide-water mixed solution, stir and mix in a water bath at 55°C for 1 hour to obtain a graphene oxide / chitosan mixed solution; graphene oxide / chitosan In the sugar mixed solution, the mass fraction of acetic acid is 1%, the concentration of chitosan is 1.0wt%, the quality of acetic acid and chitosan is 1g, and the graphene oxide-water mixed solution of 1mg / mL is 2ml;

[0052] 2) Inhale the obtained graphene oxide / chitosan mixed solution into a syringe, drop it into a 3.0wt% NaOH solution at an injection speed of 1ml / min, solidify for 12h, and wash it with deionized water until neutral;

[0053] 3) Pre-freezing with liquid nitrogen, and then vacuum-drying in a freeze dryer at -53°C for 12 hours to obtain porous microspheres with a particle size of 3-4 mm with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com