Humus soil treatment device

A treatment device and humus soil technology, applied in sludge treatment, grain treatment, water/sludge/sewage treatment, etc., can solve the problems of many equipment, poor treatment effect, low equipment integration, etc., to ensure the heating effect , improve the effect of heating and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

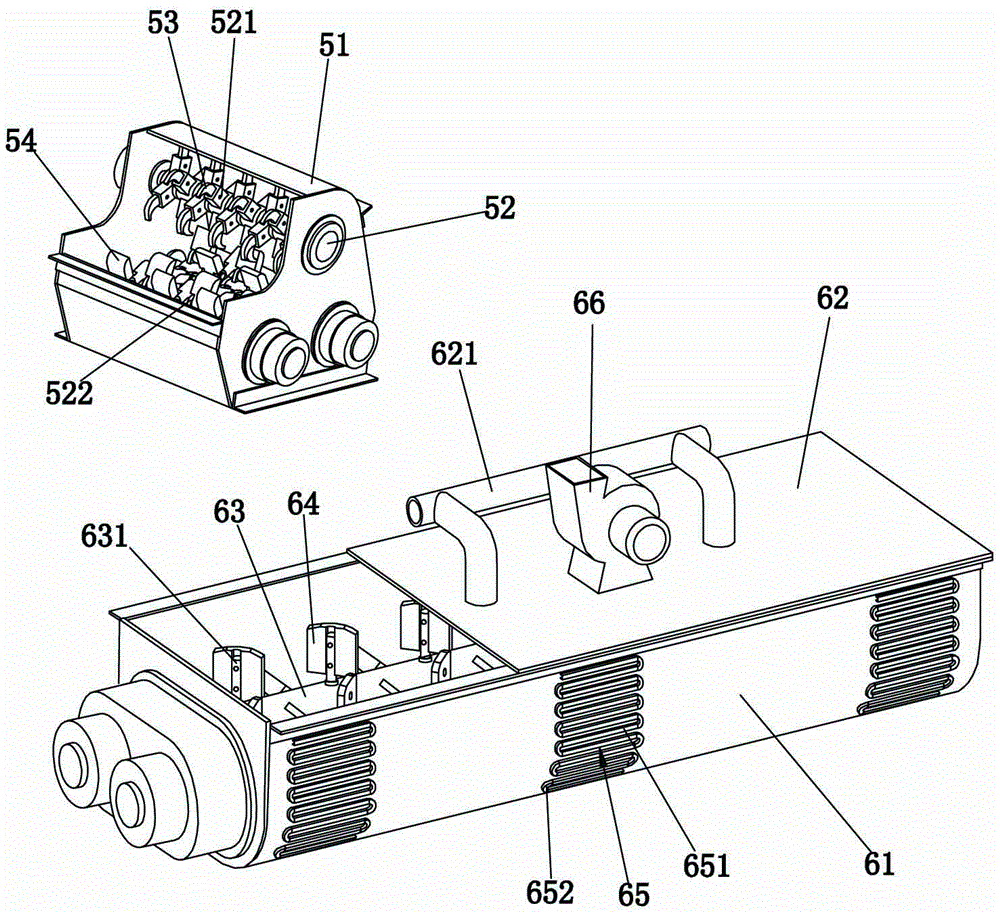

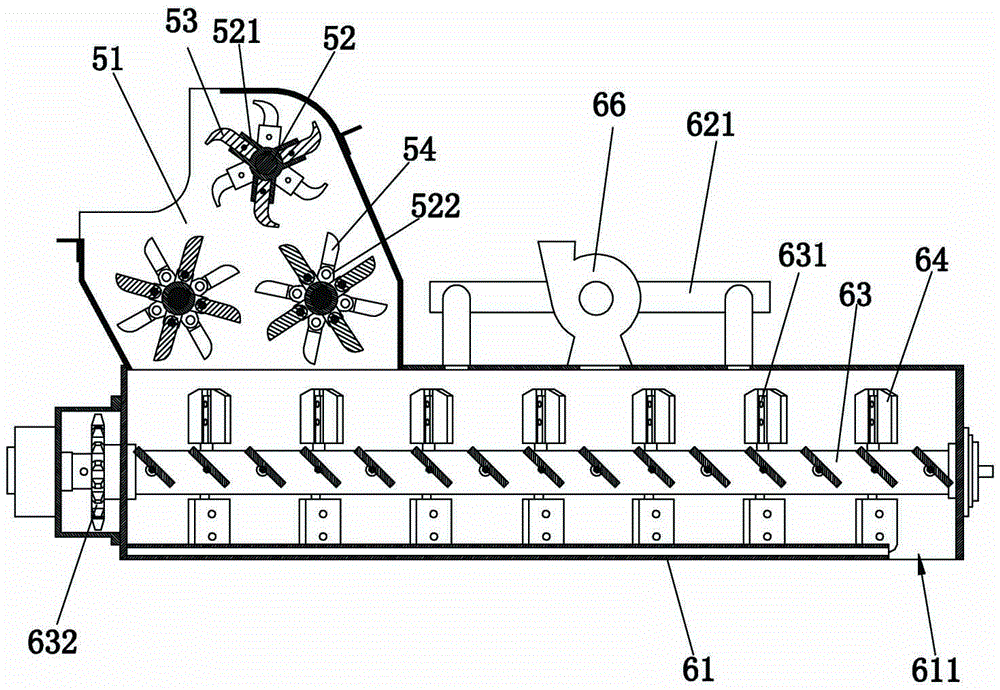

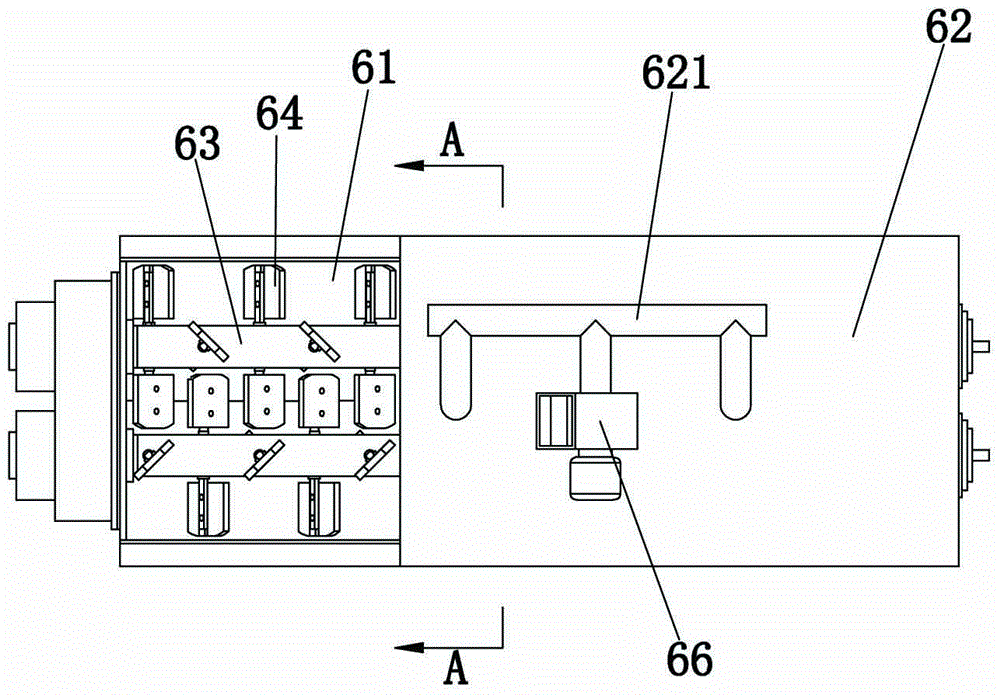

[0026] refer to figure 1 , figure 2 , image 3 and Figure 4 , a humus treatment device includes a crushing and stirring device 5 and a heating and stirring device 6 . Wherein the crushing and stirring device 5 comprises an open box body 51 at the upper and lower ends, and three first rotating shafts 52 parallel to each other and distributed in a triangle are arranged in the box body 51, wherein the circumferential surface of the first rotating shaft 52 at the apex position of the triangle A plurality of crescent-shaped rotary cutters 53 are mounted through the connecting piece 521 , and a plurality of roller hammers 54 are pivotally connected to the circumferential surfaces of the two first rotating shafts 52 at the bottom corners of the triangle through the connecting piece 522 .

[0027] refer to figure 1 , figure 2 , image 3 and Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com