Stirring device for textile fiber

A stirring device and fiber technology, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of uneven stirring of fibers, stuck textile machines, fiber lumps or lumps, etc., so as to reduce stirring The effect of unevenness, preventing the spinning machine from being stuck, and preventing work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

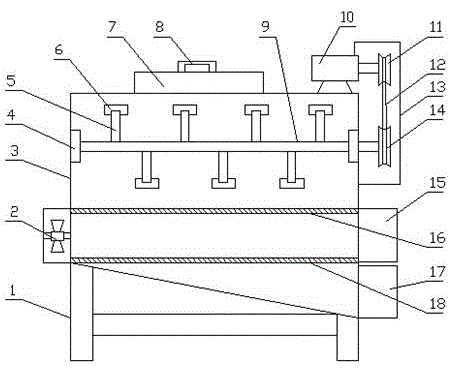

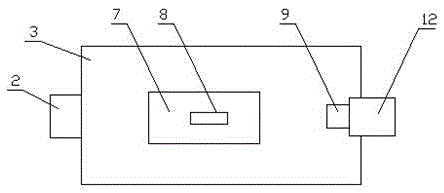

[0022] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

[0023] like figure 1 , figure 2 As shown, the structure of the textile fiber stirring device includes a base 1; the upper surface of the base 1 is provided with a cylinder 3, and the bottom surface of the cylinder 3 is an inclined surface. The fiber slides to the second discharge port 17; the upper surface of the cylinder 3 is provided with a feed door 7, which is convenient for the staff to quickly pour the fibers into the cylinder 3 during use; the feed gate 7. One side is provided with a motor 10, and the motor 10 is used to provide power for fiber stirring during use; the first pulley 11 is sleeved on one side of the motor 10, and the first pulley 11 is connected with the second pulley 14 through a V-belt 12, The second belt pulley 14 is sleeved on one end of the stirring shaft 9, and the power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com