High heating grapheme heat radiation structure

A heat dissipation structure and graphene technology, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of reduced heat utilization rate of the surface thermal layer and high heat-generating graphene composite materials cannot work normally, etc. Achieve the effect of improving heat utilization rate, ensuring normal operation, and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

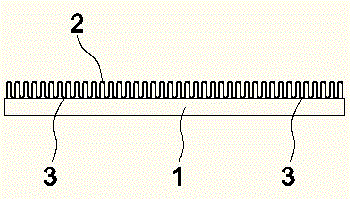

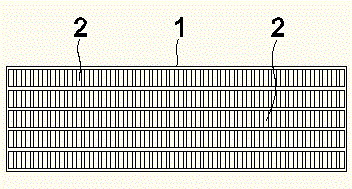

[0015] Such as figure 1 and figure 2 As shown, a heat dissipation structure of high heat generation graphene according to the present invention includes a high heat generation graphene composite material 1 , and at least one heat sink 2 is provided on the surface of the high heat generation graphene composite material 1 .

[0016] The radiator 2 is a thin aluminum material with a corrugated structure.

[0017] The surface of the heat sink 2 and the high-heating graphene composite material 1 is glued together with a thermally conductive adhesive 3 .

[0018] Five radiators 2 are arranged at certain intervals.

[0019] The beneficial effects of the present invention are:

[0020] In the heat dissipation structure of a high-heating graphene of the present invention, a plurality of thin aluminum radiators 2 arranged at a certain distance are installed on the surface of the thermal layer of the high-heating graphene composite material 1, and the thin aluminum radiators 2 are be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com