Preparation method of positive pole piece of high-rate lithium-ion battery

A technology of lithium ion battery and positive electrode plate, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of battery rate type energy difference, general cycle performance, low energy density, etc., and reduce the internal resistance of current collectors. The effect of increasing, increasing the transmission rate, and increasing the cycle rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

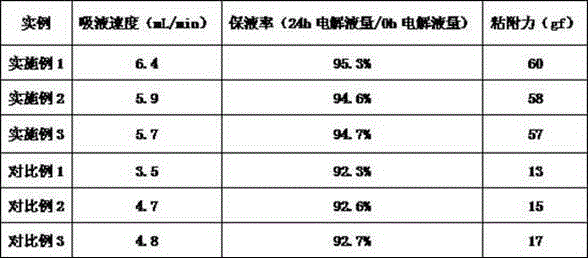

Embodiment 1

[0015] 1. The composition of the composite primer solution is as follows: Weigh 30g PVDF binder, 8g polyaniline, 0.5g benzenesulfonic acid, 10g SP conductive agent and 100g NMP organic solvent in sequence and put them into the ultrasonic disperser, and ultrasonically disperse evenly to obtain an oily composite primer coating liquid;

[0016] 2. Select the modified nickel foam with a porosity of 80%, and use the gravure printing technology to coat the above-mentioned oily composite primer solution on the nickel foam with a coating thickness of 1 μm. The surface is coated with lithium iron phosphate slurry, and dried, rolled and sliced to obtain positive electrode sheets.

Embodiment 2

[0018] 1. The composition of the composite primer solution is as follows: Weigh 5.0g PVDF binder, 5.0g polyaniline, 0.1g benzenesulfonic acid, 1.0g SP conductive agent and 100g NMP organic solvent into the ultrasonic disperser, and ultrasonically disperse evenly Obtain an oily composite primer;

[0019] 2. Select the modified nickel foam with a porosity of 60%, and use the gravure printing technology to coat the above oily composite primer solution on the nickel foam with a coating thickness of 1 μm. After drying, pass the coating machine on the nickel foam. The surface is coated with lithium iron phosphate slurry, dried, sliced, and rolled to obtain a positive electrode sheet.

Embodiment 3

[0021] 1. The composition of the composite primer solution is as follows: 50g PVDF binder, 10g polyaniline, 1.0g benzenesulfonic acid, 20g SP conductive agent and 100g NMP organic solvent were weighed in sequence and put into the ultrasonic disperser, and the ultrasonic dispersion was uniform to obtain an oily composite Primer solution;

[0022] 2. Select the modified nickel foam with a porosity of 90%, and use the gravure printing technology to coat the above-mentioned oily composite primer on the nickel foam with a coating thickness of 1 μm. After drying, pass the coating machine on the nickel foam. Lithium iron phosphate slurry on the surface, and after drying, rolling, and slicing to obtain positive electrode sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com