Single-phase shell-type energy saving transformer employing orthogonally laminated round cross-section core

An energy-saving transformer and iron core technology, applied in the field of transformers, can solve the problems of transformers affecting efficiency, etc., achieve the effect of small no-load loss, balanced flow distribution, and reduce the gap between magnetic circuit joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

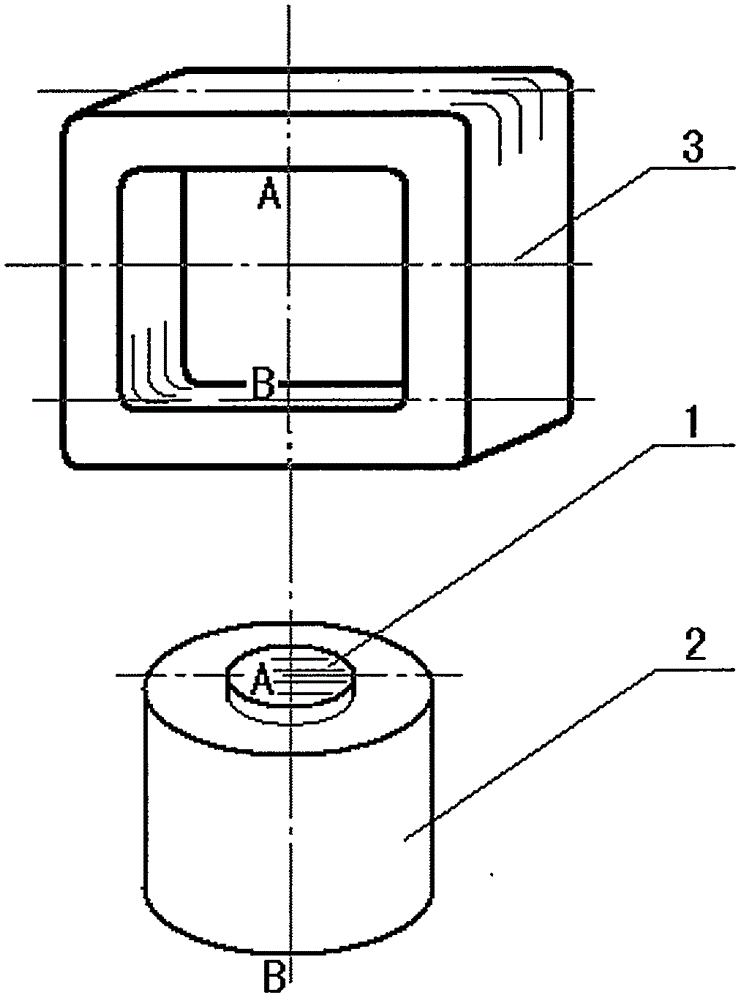

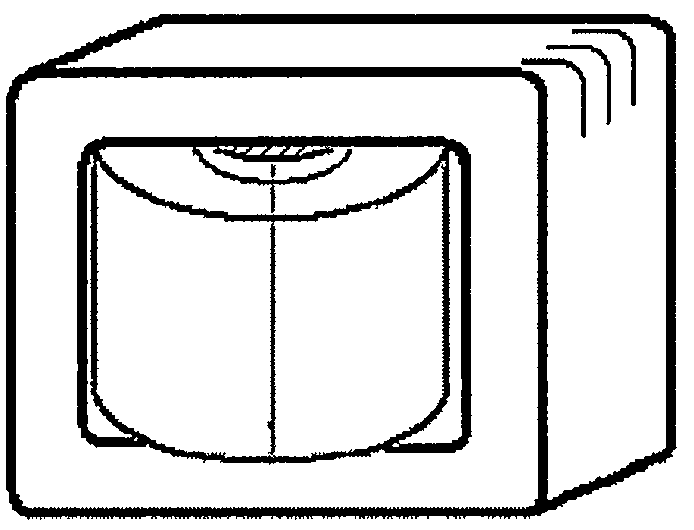

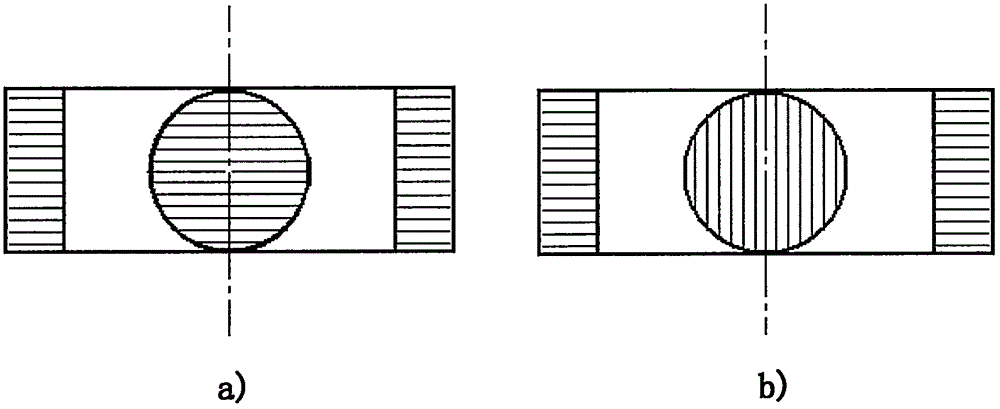

[0013] The transformer of the present invention divides the main structure into three major parts - the iron core, the magnetic yoke and the winding are manufactured independently. The iron core (1) is a magnetic circuit part on which the winding is installed, and is also the source of the magnetic force flow generated by the current in the winding. Winding (2) is an important part of electromagnetic coupling - electric chain, which includes the whole winding composed of primary winding and secondary winding. The winding can generate magnetic force lines in the iron core, and can also generate induced voltage through changes in magnetic force lines. power while the secondary output power. The yoke (3) is another part of the overall magnetic circuit, which is a channel for the flow of the magnetic field lines in the iron core and completes the magnetic chain. In shell-type transformers, since the magnetic field lines in the core can be conducted through both sides of the yoke,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com