A method for accurately measuring the leveling property of self-leveling floor paint

A technology for accurate measurement and leveling, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as poor leveling, floating color of knife marks, lap marks, etc., and achieve the effect of high-efficiency leveling and optimized formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

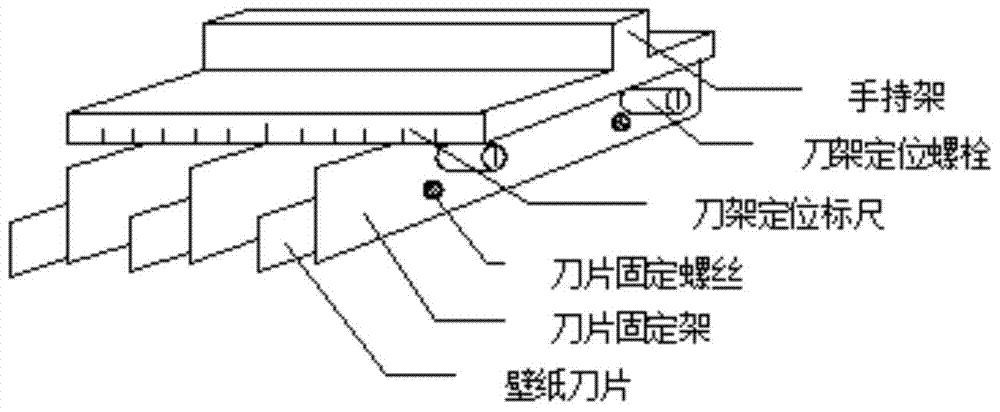

Image

Examples

Embodiment 1

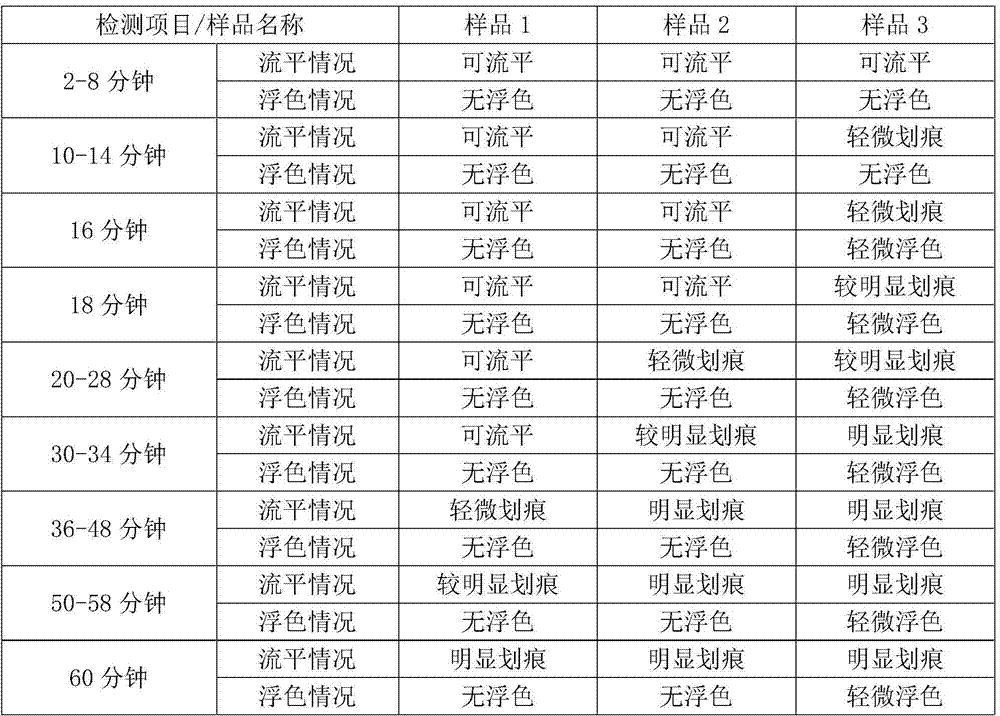

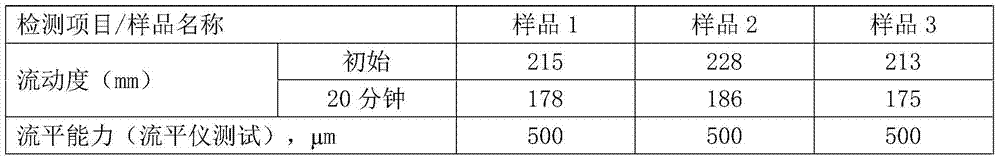

[0026] 1) Preparation of paint film: Under the standard environment, take Nippon NF SL910 solvent-free epoxy self-leveling paint (hereinafter referred to as sample 1), Nippon ZF-F910 epoxy self-leveling paint (hereinafter referred to as sample 2) and Xiupo epoxy self-leveling paint Flat paint (hereinafter referred to as sample 3) three kinds of self-leveling floor top paint (color: medium gray) were tested. The paint film of the self-leveling floor topcoat is prepared on the cement board that meets the requirements of "JC / T 412.2-2006 Fiber Cement Slab Part 2: Chrysotile Fiber Cement Slab" and has already been primed and intermediate-coated. The treatment of the cement board shall be carried out according to the regulations in "GB / T 9271-2008 Paint and Varnish Standard Test Board". Three samples according to 0.8kg / m 2 The amount of paint consumption (recommended paint consumption amount of the product) is applied to the cement board with a size of 400mm×600mm×5mm with a 3mm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com