Metal plate two-way stretching large-deformation thickened test piece

A biaxial stretching, metal sheet technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of being unsuitable for large deformation to induce micro or macro mechanical properties, cross arm fracture, uneven thickness distribution, etc., to prevent excessive Effects of early cracking, prevention of premature fracture, reduction of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

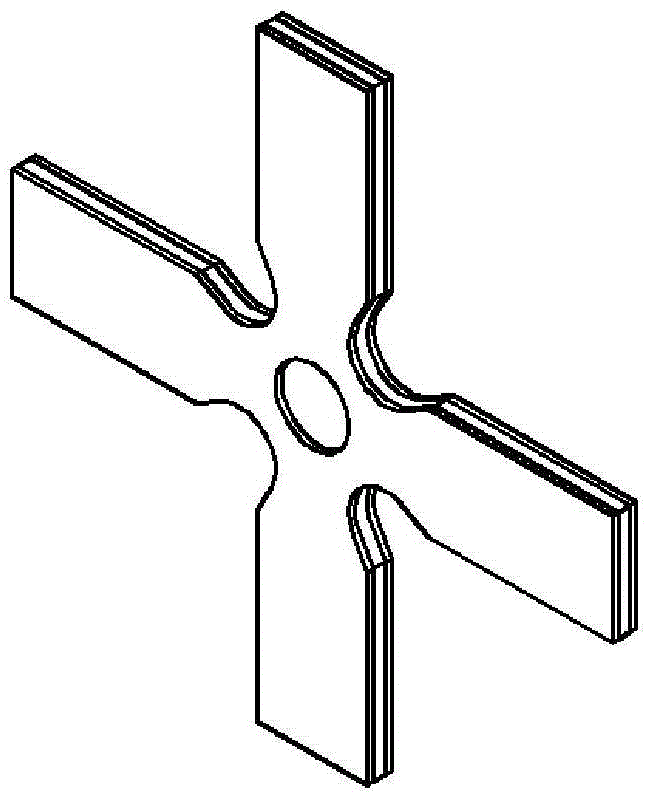

[0042] see Figure 1-a , Figure 1-b and Figure 1-c , this embodiment is the first type of test piece, that is, a thickened cross-shaped test piece around the periphery of the center point, and an arc-shaped gap is set between two adjacent cross arms, and the gap between the arc-shaped gap and the cross arms on both sides For tangential connection, it can reduce the stress concentration in the transition zone between the arms and effectively reduce the cross-sectional area of the central zone to increase the deformation of the central intersection zone.

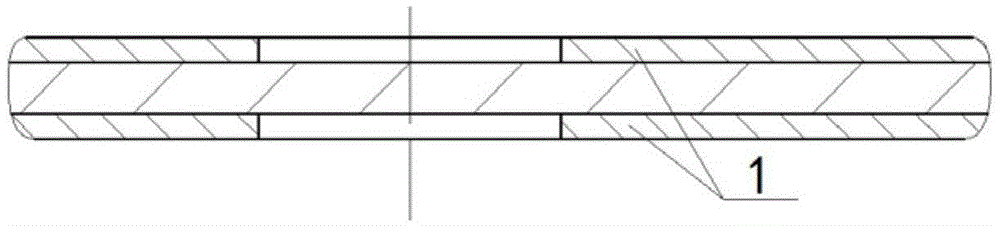

[0043] The thickened plates 1 on the four cross arms respectively extend towards the direction of the central crossing area, and extend to the periphery of the central point of the central crossing area for a circle, that is, two parts of the same thickness are symmetrically glued on both sides of the test piece to realize the surrounding of the central point. Thickened in a week.

Embodiment 2

[0045] see Figure 2-a , Figure 2-b and Figure 2-c , this embodiment is the second type of test piece, that is, a thickened cross-shaped test piece extending toward the center without contact with each other, and a circular arc transition is made between two adjacent cross arms to reduce the stress concentration in the transition area between the arms ;

[0046]The thickened plates 1 on the four cross arms respectively extend toward the direction of the central intersection area to form extensions, and the extensions do not touch each other at the central intersection area, that is, the two sides of the four cross arms are symmetrically glued to eight parts of the same thickness to achieve The non-contact thickening extending toward the center increases the load-transmitting capacity of the cross arms.

Embodiment 3

[0048] see Figure 3-a , Figure 3-b , Figure 3-c and Figure 3-d , this embodiment is the third type of test piece, that is, a cross-shaped test piece that extends to the center without contact with each other and is thickened with protrusions between the arms. Stamping to prevent premature cracking of the transition zone between the arms, so that the central cross zone can achieve large deformation;

[0049] The thickened plates 1 on the four cross arms respectively extend toward the direction of the central intersection area to form extension parts, and the extension parts do not touch each other at the central intersection area, that is, eight parts of the same thickness are symmetrically glued to both sides of the test piece, thereby increasing the thickness of the cross section. Large cross arm transfer load capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com