Automobile rolling noise test system and noise test method

A technology for noise testing and automobiles, which is applied to the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., which can solve the difficulties of testing, the inability to accurately judge the contribution of a single system to the noise in the car, and the difficulty of placing hammers or exciters, etc. problem, to achieve the effect of effective test method, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1-7 The present invention will be further described in detail with specific embodiments.

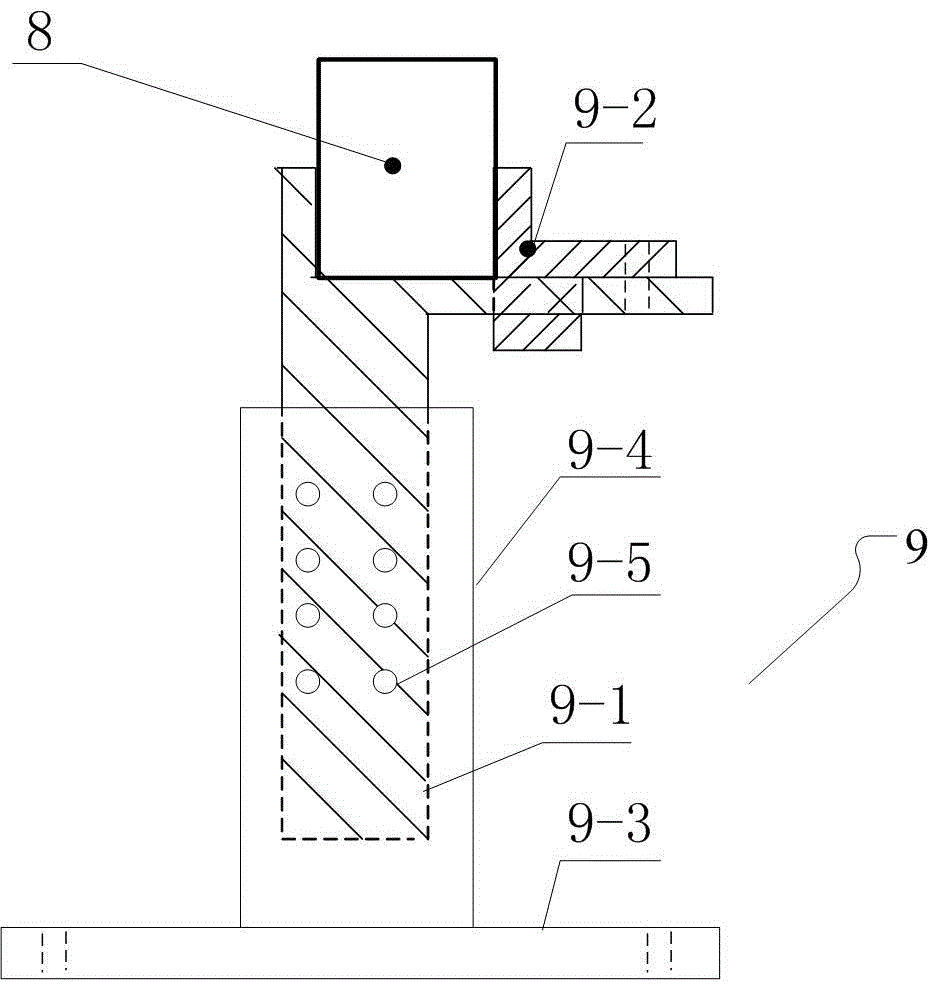

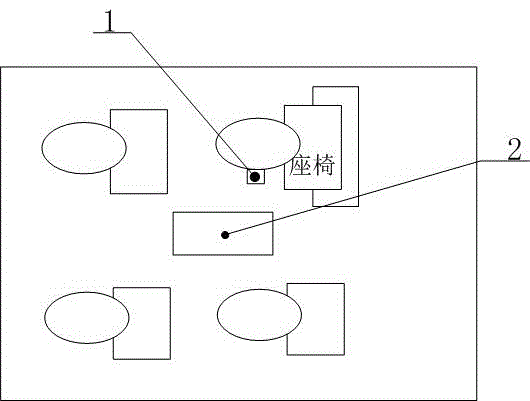

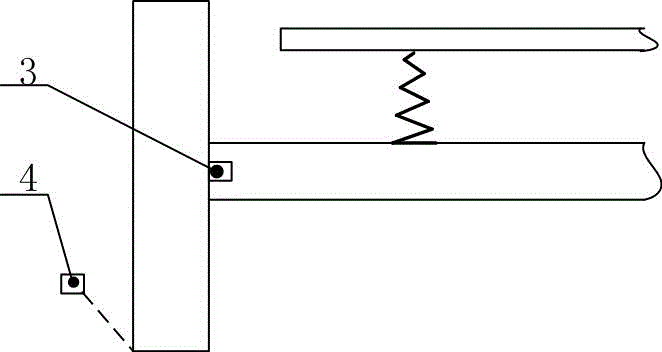

[0029] The automobile rolling noise test system adopted in this embodiment comprises: drum, microphone 1, microphone 4, vibration sensor 3, data acquisition device 2, chassis fixing device and vehicle body suspension device, wherein, microphone 4 is arranged at the place where the tire contacts the ground , used to test the radiated noise of the car tire body, and the microphone 1 is set at the position of the inner ear of the driver's side, used to test the rolling noise in the cab. The chassis fixing device includes a suspension fixing device 6 with a base 6-7, a left (or right) clamp arm 6-1, a clamp arm fixed end 6-2, a base support assembly 7 with a mounting hole 7-1, The clamp arm fixed end 6-2 is also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com