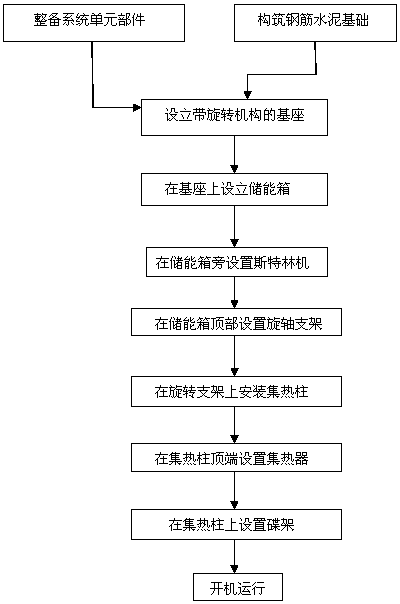

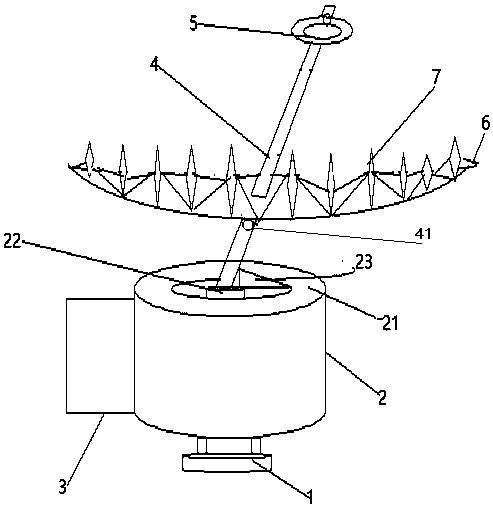

A preparation method of a solar dish system with a heat storage device

A heat storage device and solar energy technology, which is applied in the field of solar dish system preparation, can solve the problems of low operating efficiency of solar butterfly power generation devices, and achieve the effect of improving heat collection efficiency and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It is precisely because of the problems of low heat collection efficiency, low heat dissipation rate after the Stirling engine is heated up, and easy deformation of the dish frame in the dynamic operation of the existing solar dish power generation equipment. If it can be solved, it will open the door for the solar power industry to officially enter the grid. Based on this and the reason, in fact, in the field of design, manufacture and production of dish solar power generation equipment, the existing technical situation has become mature. But why is there always a problem of low power generation efficiency when the equipment is running, especially after a period of time? After detailed analysis and repeated verification, the crux of the original problem lies in the unreasonable installation procedure of the equipment, the poor stability of the mutual position and connection relationship of various components in the equipment, and the poor heat storage method.

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com