Sucker rod wellhead quick cleaning device and cleaning method thereof

A technology of cleaning device and sucker rod, applied in the field of oil well production, can solve the problems of high operating cost, low cleaning efficiency, large investment, etc., and achieve the effects of reducing thermal energy loss, good cleaning effect, and lowering cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

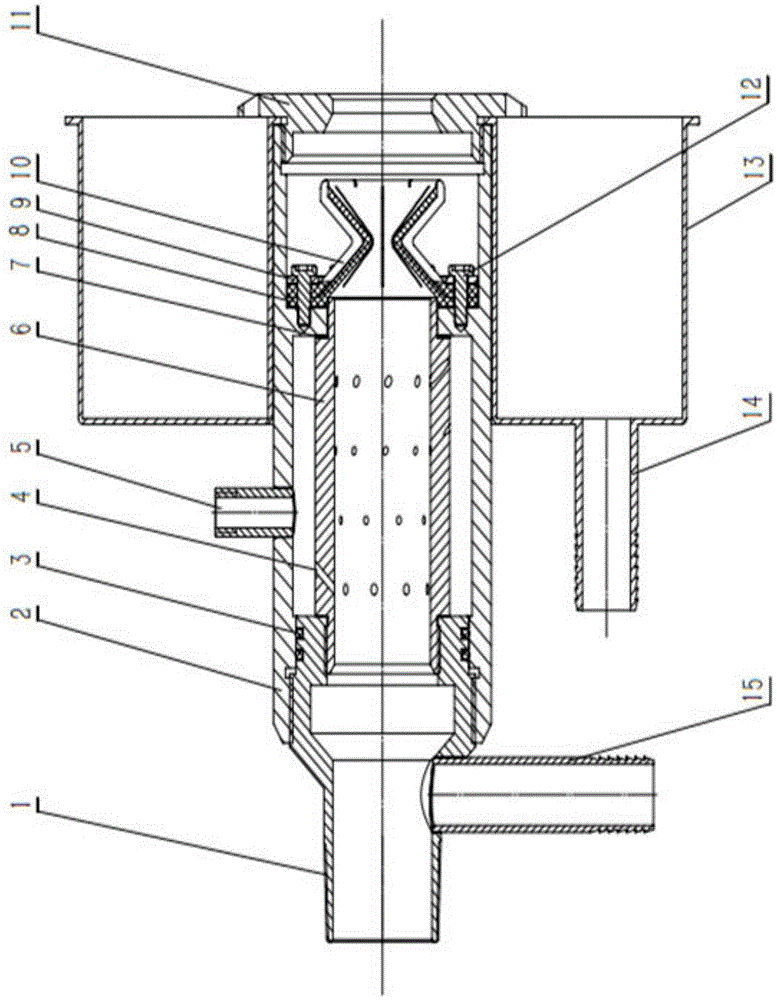

[0027] Example: A quick cleaning device for sucker rod wellhead, such as figure 1 As shown, it includes a lower joint 1, and a central pipe 6 and an outer pipe 2 respectively installed on the lower joint 1 through a threaded structure.

[0028] The lower end of the lower joint 1 is provided with an oil pipe buckle, and the oil pipe buckle is connected with the clamp head of the oil production wellhead, and the side of the lower joint 1 is provided with a dirty liquid outlet joint 15 .

[0029] The outer tube 2 is sleeved on the outside of the central tube 6, and the middle section of the inner wall of the outer tube 2 and the top of the central tube 6 are respectively provided with matching step surfaces, and the step surface on the inner wall of the outer tube 2 sits on the step surface at the top of the central tube 6 On the top, the gap between the outer tube 2 and the central tube 6 is isolated into a sealed cavity, the lower end of the outer tube 2 and the threaded conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com