Thick-gauge ultra-deep drawing cold rolled steel plate and manufacturing method thereof

A technology of cold-rolled steel sheets and manufacturing methods, applied in the field of ultra-deep-drawn cold-rolled steel sheets, capable of solving problems such as insufficient reduction rate and substandard stamping performance of ultra-deep-drawn cold-rolled steel sheets, and achieving good stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

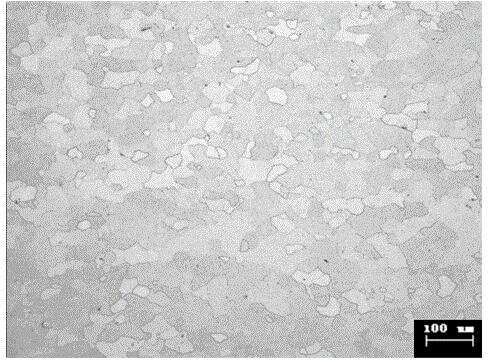

Image

Examples

Embodiment Construction

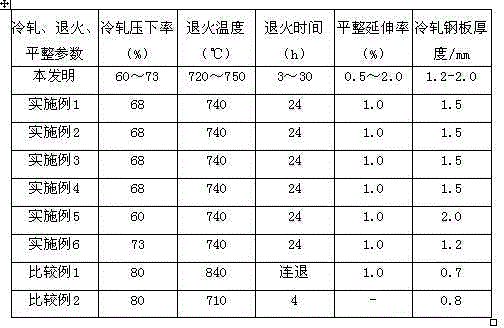

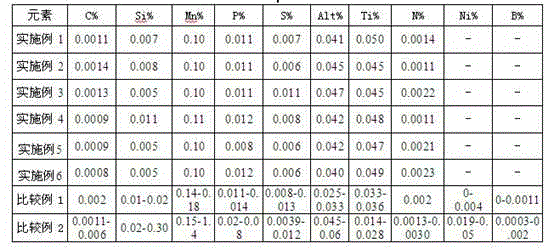

[0050] Below in conjunction with embodiment 1~6 and comparative example 1—disclosed in the Chinese patent publication number CN102884213A, comparative example 2—disclosed in the Chinese patent publication number CN101135025A, the present invention is further described, as shown in table 1~table 4 .

[0051] Table 1 Chemical composition of the present invention (% by weight), the balance is Fe and unavoidable impurities.

[0052]

[0053] According to the requirements of the material composition design of the present invention, pre-desulfurization of molten iron is adopted, combined blowing at the top and bottom of the converter, Ar blowing at the bottom of the Ar blowing station ensures stirring, and RH furnace vacuum circulation degassing treatment ensures that the pure degassing time of RH is more than 10 minutes, and the whole process is blown. Ar protection casting, cutting into length continuous casting slabs after casting.

[0054] After the continuous casting slab i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com