Method for improving gasoline quality by etherifying light gasoline

A technology for light gasoline and gasoline, applied in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve problems such as high octane number and pollution, achieve high conversion rate, increase the amount of etherification reaction, and increase environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for improving gasoline quality through etherification of light gasoline, the steps are as follows:

[0026] 1) Separating and hydrotreating catalytic gasoline to obtain light gasoline from which diolefins have been removed;

[0027] 2) Washing the light gasoline from which diolefins have been removed in step 1) with water to remove the poisoned substance of the etherification catalyst in the light gasoline, and then dehydrating;

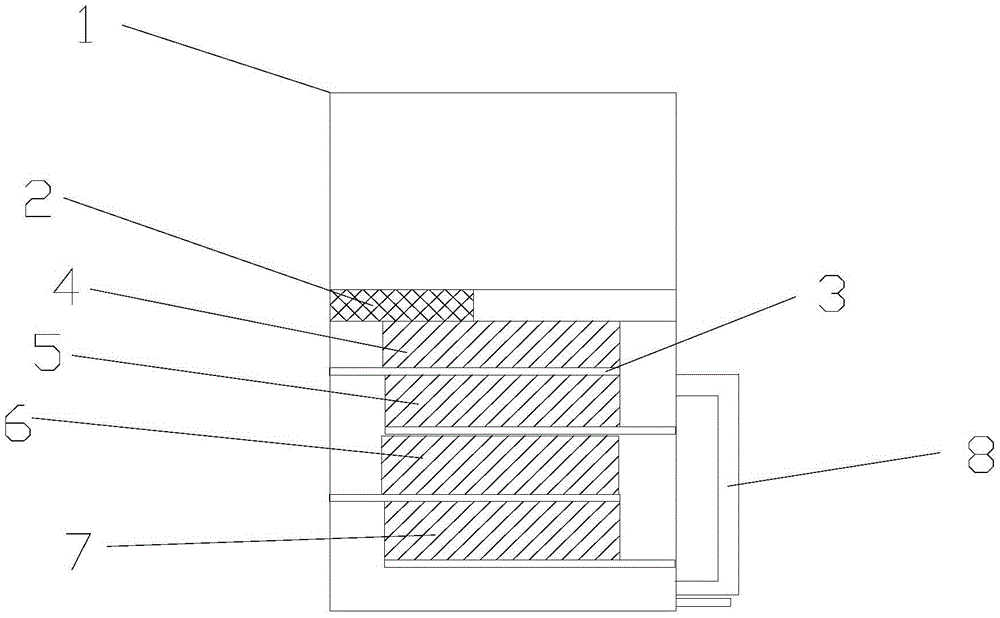

[0028] 3) Light gasoline and ethanol after dehydration in step 2) enter the etherification reaction part according to the mole of ethanol: active olefin is 1.6, the primary etherification reaction bed, the secondary etherification reaction bed, the tertiary etherification reaction bed and the four-stage etherification reaction bed The grade etherification reaction bed is arranged in the etherification reaction device in turn, and the reactant after reaction treatment flows out from the reactor, and the effluent is TAME, C 5 The mixtu...

Embodiment 2

[0031] A method for improving gasoline quality through etherification of light gasoline, the steps are as follows:

[0032] 1) Separating and hydrotreating catalytic gasoline to obtain light gasoline from which diolefins have been removed;

[0033] 2) Washing the light gasoline from which diolefins have been removed in step 1) with water to remove the poisoned substance of the etherification catalyst in the light gasoline, and then dehydrating;

[0034] 3) Light gasoline and ethanol after dehydration in step 2) enter the etherification reaction part according to the mole of ethanol: active olefin is 1.8, the primary etherification reaction bed, the secondary etherification reaction bed, the tertiary etherification reaction bed and the four-stage etherification reaction bed The grade etherification reaction bed is arranged in the etherification reaction device in turn, and the reactant after reaction treatment flows out from the reactor, and the effluent is TAME, C 5 The mixtu...

Embodiment 3

[0037] As in Example 1, the etherification reaction conditions are at a temperature of 55°C, a pressure of 1.0MPa, and 0.8h -1 liquid space velocity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com