Waterborne nitrocotton brightener and preparation method thereof

A technology of nitrocellulose and brightening agent, applied in the direction of water-based dispersant, etc., can solve the problems of poor gloss retention and poor stability of water-based nitrocellulose emulsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of aqueous nitrocellulose brightener, comprises the following steps:

[0037] A) In parts by weight, 50-150 parts of nitrocellulose, 0.2-5 parts of rosin resin and 300-7001 parts of mixed solvent are mixed to obtain a nitrocellulose solution,

[0038] The mixed solvent includes a first solvent and a second solvent, and the first solvent includes ethylene glycol butyl ether acetate;

[0039] Described second solvent comprises one or more in isooctyl acetate, butyl acetate and ethylene glycol butyl ether;

[0040] B) Mix 30-100 parts of plasticizer, 8-45 parts of emulsifier, 200-600 parts of water and the nitrocellulose solution obtained in the step A), and emulsify to obtain a water-based nitrocellulose brightener.

[0041] In the present invention, the nitrocellulose is first dissolved, and 50 to 150 parts of nitrocellulose, 0.2 to 5 parts of rosin resin and 300 to 700 parts of mixed solvent are mixed to ...

Embodiment 1

[0058] (1) Dissolving nitrocellulose:

[0059] Add 400g of mixed solvent (200g of isooctyl acetate, 200g of ethylene glycol butyl ether acetate) into the reaction kettle, add 0.5g of rosin resin and 100g of 1 / 2S nitrocellulose under stirring, stir for 0.5 hours, the rosin resin and nitrocellulose are fully dissolved , to obtain the nitrocellulose solution;

[0060] (2) Phase inversion emulsification:

[0061] Add 80 g of epoxidized soybean oil and 5 g of castor oil polyoxyethylene ether into the nitrocellulose solution under stirring, stir for 10 minutes, stop stirring, add 10 g of fatty alcohol polyoxyethylene ether that has been uniformly mixed with 400 g of deionized water in advance, and let stand Stratification for 60 minutes, high-speed emulsification for 60 minutes and discharge to obtain the product;

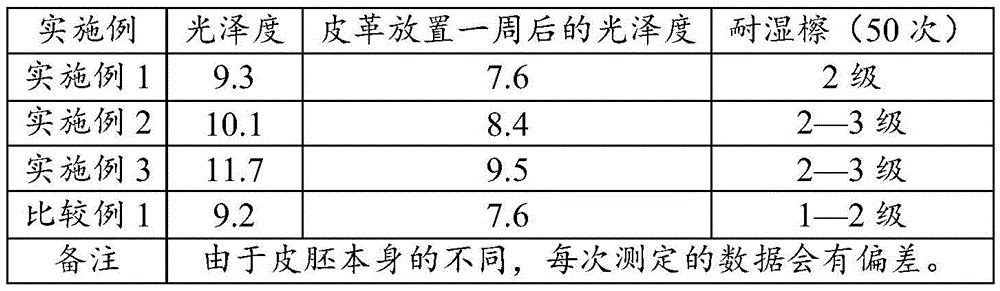

[0062] The present invention has measured the glossiness of water-based nitrocellulose brightener in the present embodiment according to paper and cardboard specular g...

Embodiment 2

[0065] (1) Dissolving nitrocellulose:

[0066] Add 540g of mixed solvent (270g of ethylene glycol butyl ether acetate, 270g of isooctyl acetate) into the reaction kettle, add 1.5g of rosin resin and 120g of 1 / 2S nitrocellulose under stirring, stir for 1 hour, and the rosin resin and nitrocellulose are fully dissolved , to obtain the nitrocellulose solution;

[0067] (2) Phase inversion emulsification:

[0068] Add epoxy soybean oil 60g and castor oil polyoxyethylene ether 7.5g into the nitrocellulose solution under stirring, stir for 10 minutes, stop stirring, add fatty alcohol polyoxyethylene ether 15g that has been uniformly mixed with deionized water 300g in advance, and statically Set the layers for 60 minutes, high-speed emulsification for 60 minutes and discharge to obtain the product;

[0069] The present invention has measured the glossiness of water-based nitrocellulose brightener in the present embodiment according to paper and cardboard specular gloss measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com