Commercial vehicle reclaimed modified fender material and preparation method thereof

A technology for commercial vehicles and fenders, which is applied in the field of regenerated and modified fender materials for commercial vehicles and its preparation, can solve problems such as resource recycling and reuse, and achieve cost savings, excellent processing performance, and best mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

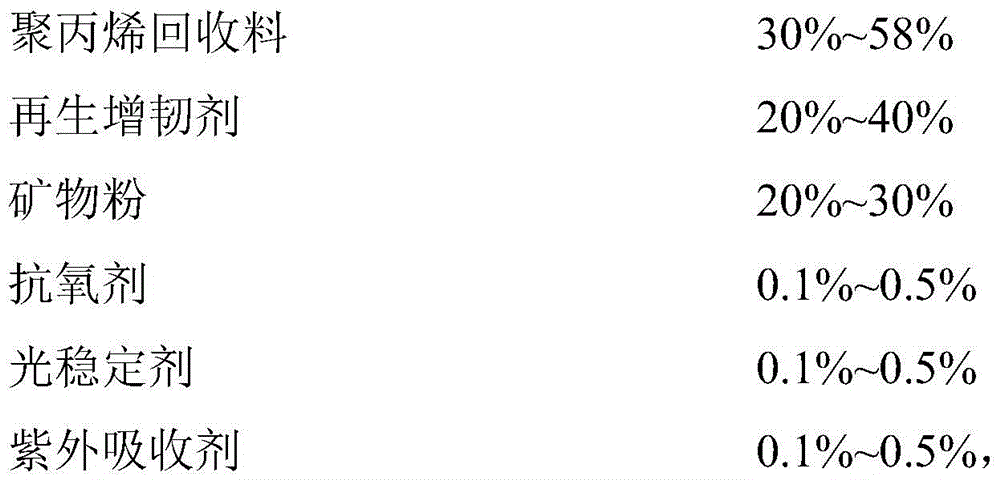

[0026] The regenerated and modified fender material for commercial vehicles of the present invention comprises the following components in parts by weight: 30 parts by weight of polypropylene reclaimed material for automobile bumper; Material and LLDPE film material are compounded according to the mass ratio of 1:1:2; 30 parts by weight of mineral powder are surface-treated mica powder with a particle size of 1800 mesh; 0.2 parts by weight of DLTP thioester antioxidant; HS- 0.3 parts by weight of 362 hindered amine light stabilizer; 0.5 parts by weight of UV-327 benzotriazole ultraviolet absorber.

[0027] The commercial vehicle regeneration modified fender material preparation process of the present invention comprises the following steps,

[0028] Step 1: Prepare raw materials, weigh each component according to weight composition, put the weighed recycled polypropylene material and recycled toughening agent in a high-speed mixer, add a very small amount of white oil, pre-mix...

Embodiment 2

[0031] The regenerated and modified fender material for commercial vehicles of the present invention comprises the following components in parts by weight: 40 parts by weight of polypropylene reclaimed material for automobile bumpers; Material and LLDPE film material are compounded according to the mass ratio of 1:1:2; 24 parts by weight of mineral powder are surface-treated wollastonite, and the particle size is 2200 mesh; 0.2 parts by weight of DSTP thioester antioxidant; HS 0.4 parts by weight of -962 hindered amine light stabilizer; 0.4 parts by weight of UV-326 benzotriazole ultraviolet absorber.

[0032] The commercial vehicle regeneration modified fender material preparation process of the present invention comprises the following steps,

[0033] Step 1: Prepare the raw materials, weigh each component according to the weight composition, put the weighed recycled polypropylene material and recycled toughening agent in a high-speed mixer, add a very small amount of white ...

Embodiment 3

[0036] The regenerated and modified fender material for commercial vehicles of the present invention comprises the following components in parts by weight: 50 parts by weight of polypropylene reclaimed material for refrigerator trays; It is compounded with LLDPE film material according to the mass ratio of 1:1:2; 25 parts by weight of mineral powder is surface-treated talc powder, and the particle size is 2800 mesh; 0.2 part by weight of DSTP thioester antioxidant; HS-962 0.5 parts by weight of hindered amine light stabilizer; 0.3 parts by weight of UV-326 benzotriazole ultraviolet absorber.

[0037] The commercial vehicle regeneration modified fender material preparation process of the present invention comprises the following steps,

[0038]Step 1: Prepare raw materials, weigh each component according to the weight composition, put the weighed recycled polypropylene material and recycled toughening agent in a high-speed mixer, add a very small amount of white oil, pre-mix at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com