Non-woven fabric raw material and preparation method thereof, and preparation method of non-woven fabric

A technology for non-woven fabrics and raw materials, applied in the field of non-woven fabric raw materials and their preparation, can solve the problems of insufficient softness, difficult processing, and uneven dispersion, and achieve excellent safety and hygiene, high softness and strength. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

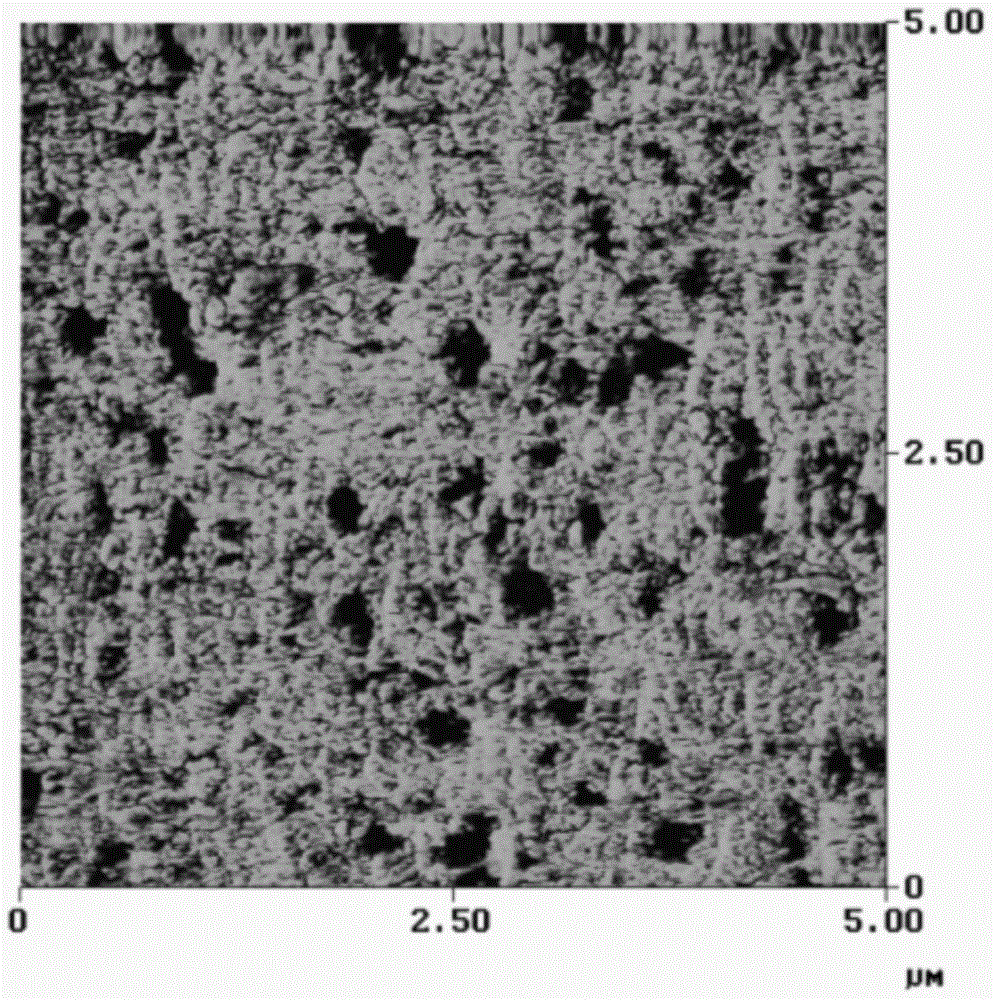

Image

Examples

preparation example Construction

[0079] According to the preparation method of the present invention, the first olefin polymerization conditions may include: a temperature of 50-100°C, preferably 60-95°C; a pressure of 1-8 MPa, preferably 1.2-5.5 MPa; and a time of 30-180 minutes , Preferably 45-120 minutes. In the present invention, pressure refers to the gauge pressure of the reactor.

[0080] The reactor for the gas phase polymerization of olefins can be a horizontal stirred bed reactor, a vertical stirred bed reactor, a fluidized bed reactor, etc., and the above gas phase reactors can be arbitrarily combined.

[0081] According to the preparation method of the present invention, the olefin gas phase polymerization conditions may include: a temperature of 50-100°C, preferably 60-95°C; a pressure of 1-4 MPa, preferably 1.2-3.5 MPa; and a time of 10-180 minutes, Preferably it is 10-90 minutes.

[0082] According to the present invention, the method may include mixing the polypropylene composition, nucleating agen...

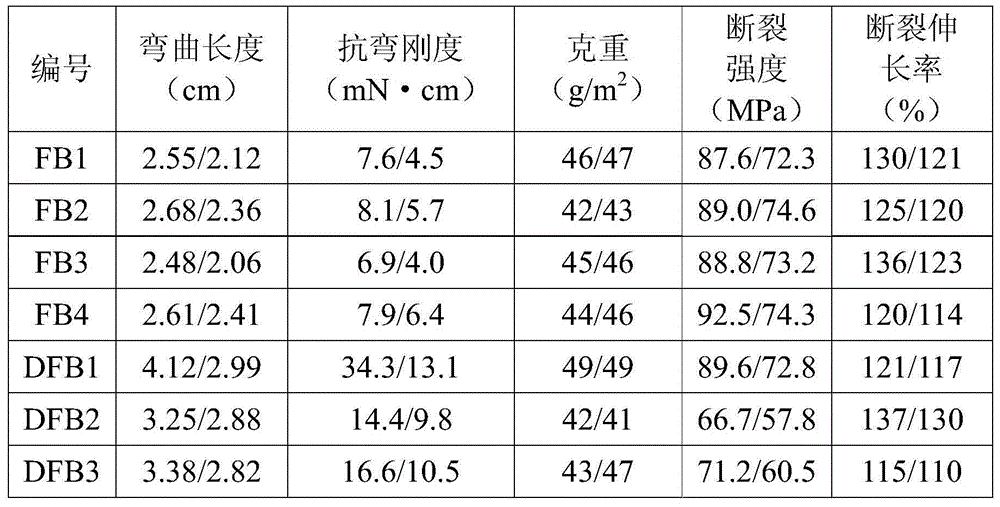

Embodiment 1

[0112] This embodiment is used to illustrate the non-woven fabric raw material and the preparation method thereof and the preparation method of the non-woven fabric of the present invention.

[0113] (1) Preparation of non-woven fabric raw materials

[0114] The polymerization reaction was carried out on the above-mentioned horizontal gas phase polypropylene pilot plant, the catalyst particle size used was 59 microns, and the reaction was carried out according to the above-mentioned method. The external electron donor used is diisopropyldimethoxysilane, the polymerization reaction in the first reactor is propylene homopolymerization, the polymerization temperature is 66° C., the reaction pressure is 2.3 MPa, and the residence time is about 90 minutes. The melt index of the component (a) obtained by the reaction is 42.6 g / 10 min.

[0115] The second reactor is propylene copolymerization to prepare component (b). Ethylene and propylene are added to the reactor. The polymerization temp...

Embodiment 2

[0120] This embodiment is used to illustrate the non-woven fabric raw material and the preparation method thereof and the preparation method of the non-woven fabric of the present invention.

[0121] (1) Preparation of non-woven fabric raw materials

[0122] The non-woven fabric material was prepared by the same method as in Example 1, except that 800 ppm of nucleating agent NX8000 was used instead of 500 ppm of nucleating agent Millad 3988 in Example 1.

[0123] (2) Preparation of non-woven fabric

[0124] A non-woven fabric was prepared by the same method as in Example 1 to obtain a non-woven fabric FB2, the properties of which are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com