Nostoc sphaeroides polysaccharide and extracting method thereof

An extraction method, the technology of kudzu rice flour, applied in the chemical industry, can solve the problems of high cost, many processes, energy consumption and time consumption, and achieve the effect of reducing extraction cost, improving preparation efficiency and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

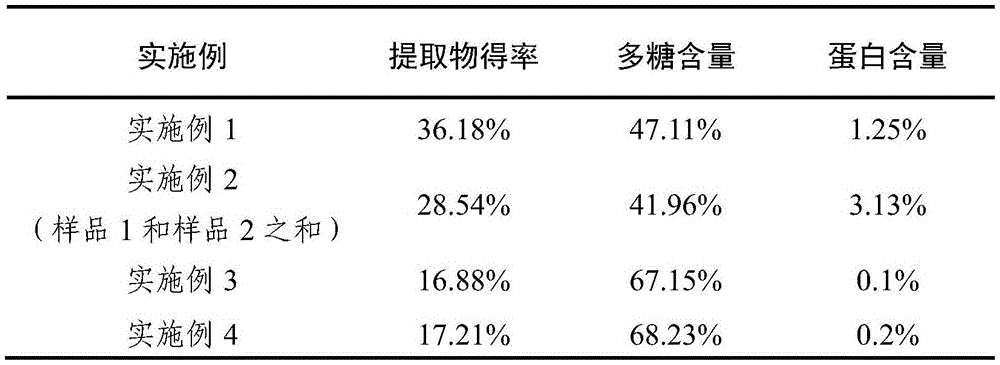

Examples

Embodiment 1

[0047] Step 1: Preparation of materials: Select kudzu rice and dry it at 60° C. for 2 hours; grind the dried kudzu rice and pass through a 80-mesh sieve to obtain kudzu rice flour.

[0048] Step 2: Soaking: Soak the kudzu rice noodles with purified water, the weight ratio of kudzu rice noodles to purified water is 1:30, and the soaking time is 24 hours, so as to obtain the soaked kudzu rice.

[0049] Step 3: water extraction: add purified water to the soaked kudzu rice, the ratio of solid to liquid is 1:15 (purified water with 15 times the quality of kudzu rice after water absorption is added), the extraction temperature is 90°C, and the extraction time After 2 hours, the feed liquid was cooled to room temperature and centrifuged to discard the feed slag, and the feed liquid was collected to obtain an extract.

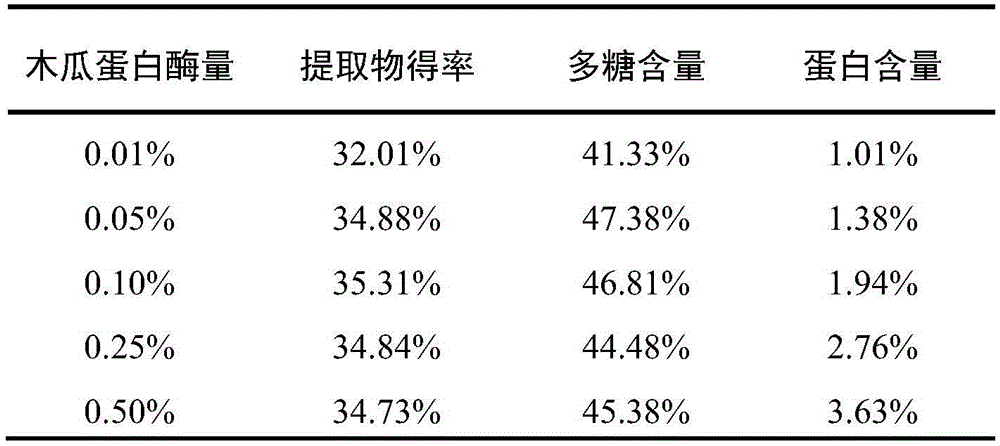

[0050] Step 4: Enzymolysis: the extract is heated to 55°C, and the papain (10% of the volume of the extract) is added to the extract. 4 u / g) (w / v), enzymatic hydrolys...

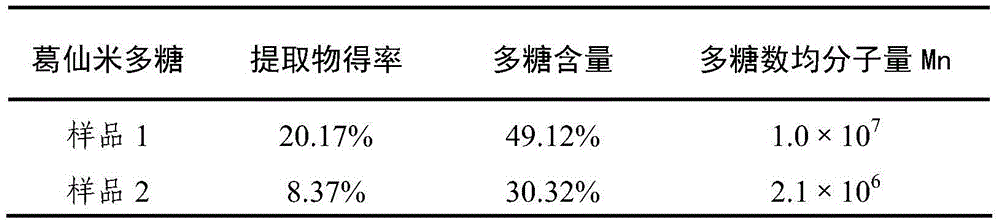

Embodiment 2

[0056] Step 1: Preparation of materials: Select kudzu rice and dry it at 80° C. for 1 hour; grind the dried kudzu rice and pass through a 50-mesh sieve to obtain kudzu rice flour.

[0057] Step 2: Soaking: Soak the kudzu rice noodles with purified water, the weight ratio of kudzu rice noodles to purified water is 1:10, and the soaking time is 2 hours, so as to obtain the soaked kudzu rice.

[0058] Step 3: water extraction: add purified water to the soaked kudzu rice, the ratio of solid to liquid is 1:8 (purified water with 8 times the quality of kudzu rice after water absorption is added), the extraction temperature is 100°C, and the extraction time is After 1 hour, the feed liquid was cooled to room temperature and centrifuged to discard the feed slag, and the feed liquid was collected to obtain an extract.

[0059] Step 4: Enzymolysis: the extract is heated to 40°C, and the papain (10% of the volume of the extract) is added to the extract. 4 u / g) (w / v), enzymatic hydrolysi...

Embodiment 3

[0065] Step 1: Preparation of raw materials: Select kudzu rice and dry it at 50° C. for 5 hours; grind the dried kudzu rice and pass through a 100-mesh sieve to obtain kudzu rice flour.

[0066] Step 2: Soaking: Soak the kudzu rice noodles with purified water, the weight ratio of kudzu rice noodles to purified water is 1:80, and the soaking time is 24 hours, so as to obtain the soaked kudzu rice.

[0067] Step 3: water extraction: add purified water to the soaked Gexian rice, the ratio of solid to liquid is 1:20 (adding purified water 20 times the quality of Ge Xianmi after water absorption), the extraction temperature is 80°C, and the extraction time is 1:20. After 5 hours, the feed liquid was cooled to room temperature and centrifuged to discard the feed slag, and the feed liquid was collected to obtain an extract.

[0068] Step 4: Enzymolysis: the extract is heated to 70°C, and the papain (10% of the volume of the extract) is added to the extract. 4 u / g) (w / v), enzymatic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com