A kind of method for preparing 1,2-pentanediol from xylose

A technology of pentanediol and xylose, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as difficulty in the source of C5 components, reduce reaction cost and separation difficulty, reduce dosage, The effect of reducing the reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0028] Preparation of Silica Supported Rh Catalyst

[0029] Weigh a certain amount of RhCl 3 ·xH 2 O (Rh: 39.5wt%) was added into deionized water and stirred to dissolve, and the amount of water added was determined according to the amount of silicon oxide added. To the above RhCl 3 Add gas-phase nano silicon oxide to the aqueous solution, stir well to form a paste, let stand for 24 hours, and dry at 120°C for 12 hours. Wherein the mass ratio of metal rhodium mass to carrier is X. The catalyst was reduced at 300°C for 2h in a hydrogen atmosphere before use.

[0030] Preparation of Silica Supported Rh Catalyst Modified by Auxiliary M (M=Re, Mo, W)

[0031] Weigh a certain amount of additive precursor into deionized water and stir to dissolve. Add a certain amount of the dried silicon oxide-supported Rh catalyst to the solution, stir well to form a paste, let stand for 24 hours, and dry at 120° C. for 12 hours. Among them, the auxiliary agent precursors are respectively s...

Embodiment 7-10

[0035] RhCl in embodiment 1 3 ·xH 2 O to PdCl 2 , add a small amount of hydrochloric acid during the dissolution process. Other catalyst preparations, additive introduction methods and catalytic reactions are the same as in Example 3, and the reaction results are shown in Table 3.

Embodiment 11-14

[0037] Adopt the commercially purchased Rh / Ac (5wt%) or Pd / Ac (5wt%) catalyst to replace the Rh / SiO prepared in embodiment 3 2 catalyst. The auxiliary agent introduction method and catalytic reaction conditions are the same as in Example 3, and the reaction results are shown in Table 1.

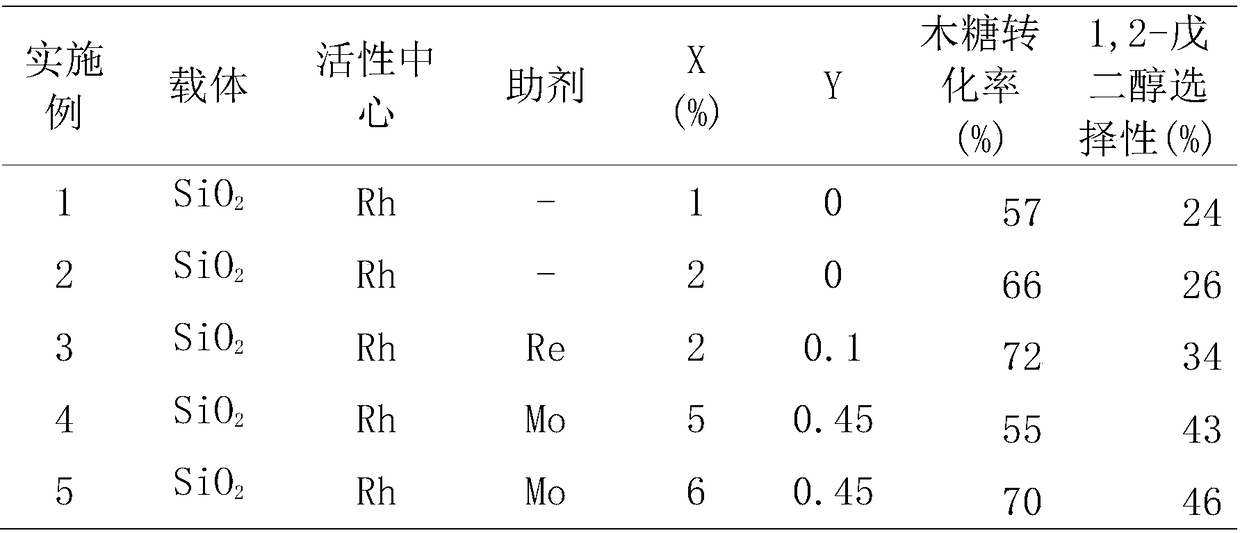

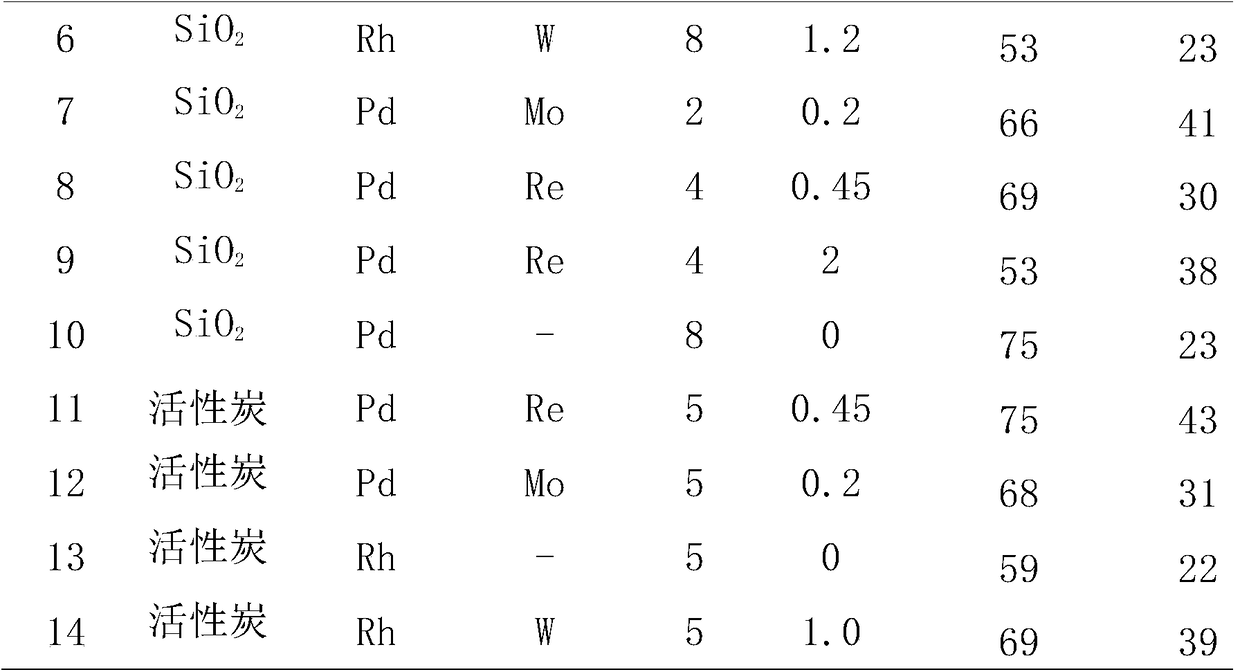

[0038] Table 1 Effect of catalyst composition on xylose hydrogenation performance

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com