Spiral aeration method and spiral aeration tank

An aeration method and aeration tank technology, which are applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as poor mixing uniformity, low reaction efficiency, and large footprint , to achieve uniform flow field, improve processing efficiency, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention provides a spiral aeration method and a spiral aeration tank. In order to make the object, technical scheme and effect of the present invention clearer and clearer, the present invention is further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

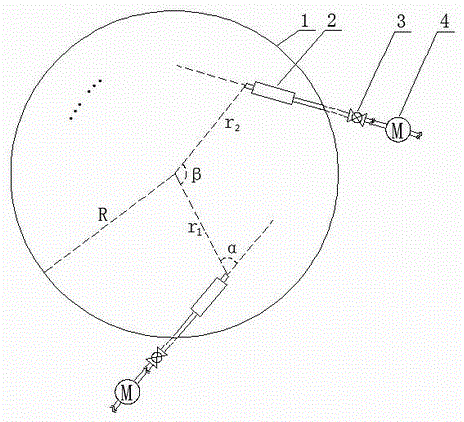

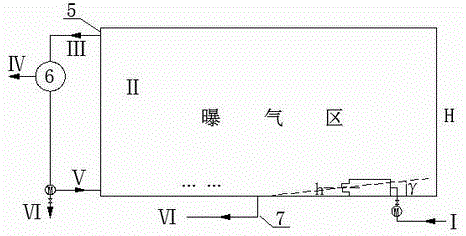

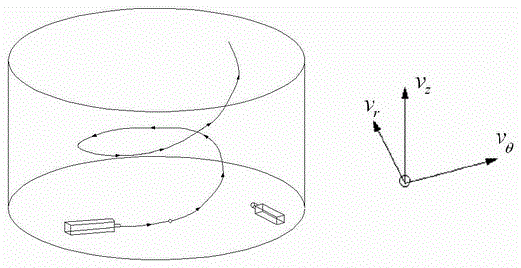

[0036] refer to figure 1 , figure 2 In the example of the present invention, a spiral aeration tank with a spiral flow field and a spiral aeration method mainly include: an aeration tank body 1, a jet aeration device 2, a flow regulator 3, a water pump 4, a water outlet tank 5, Secondary sedimentation tank 6, mud discharge pipe 7.

[0037] The jet aeration device 2 is installed at the bottom of the aeration tank, and the height of the jet aeration from the bottom is h. The jet flow direction of the jet aeration device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com