Compound lead chlorate and lead chlorate infrared nonlinear optical crystal, preparation method and use

A non-linear optics, lead chlorate technology, applied in chemical instruments and methods, chloric acid, chlorate, etc., can solve the problem that the research of new frequency conversion crystal needs to be strengthened, and achieves air stability, short reaction time, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (adopting melt method)

[0036] Synthetic lead chlorate (Pb 2.14 OCl 2.28 ) compounds:

[0037] Using the solid phase reaction method, according to the chemical equation: 1.14PbCl 2 +PbO→Pb 2.14 OCl 2.28 Synthesis of lead chlorate compounds:

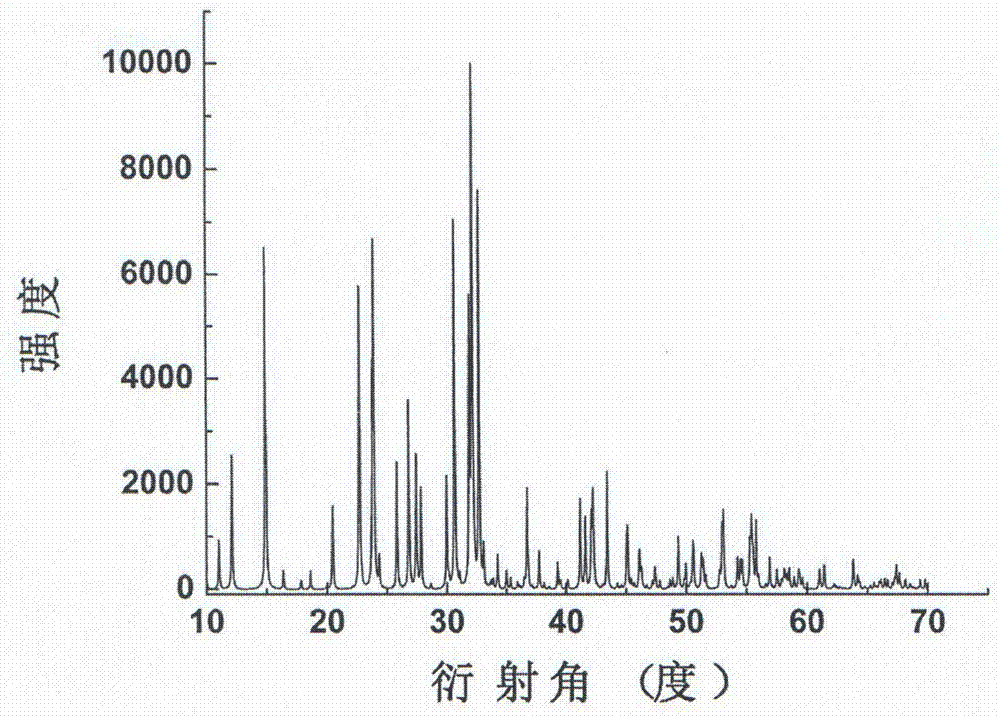

[0038] PbCl 2, PbO was put into a mortar with a stoichiometric ratio of 1.14:1, mixed and carefully ground, then put into a corundum crucible with an opening of Φ400mm×400mm, compacted, put into a muffle furnace, and slowly heated up to 300°C, Constant temperature for 24 hours, take out the crucible after cooling, the sample is relatively loose at this time, then take out the sample and grind it evenly, then put it in the crucible, keep the temperature in the muffle furnace at 430°C for another 48 hours, take it out, put it in the mortar Smash and grind to get the lead chlorate compound, carry out X-ray analysis to this product, the obtained X-ray spectrogram is consistent with that of Pb 2.14 OCl 2.28 The X-...

Embodiment 2

[0046] According to the reaction formula 1.14PbCl 2 +Pb(CO 3 ) 2 →Pb 2.14 OCl 2.28 +CO 2 ↑ Synthesis of Pb 2.14 OCl 2.28 Compound, specific operation steps are carried out according to embodiment 1;

[0047] Preparation of Pb by Pulling Method 2.14 OCl 2.28 Crystal:

[0048] a, the synthesized Pb 2.14 OCl 2.28 Put the compound into an open platinum crucible of Φ100mm×100mm, heat it to a temperature of 600°C, and keep the temperature constant for 5 hours to obtain a mixed melt of lead chlorate;

[0049] b. Preparation of lead chlorate seed crystals: Slowly lower the mixed melt or mixed melt obtained in step a to room temperature at a rate of 0.5° C. / h, and spontaneously crystallize to obtain lead chlorate seed crystals;

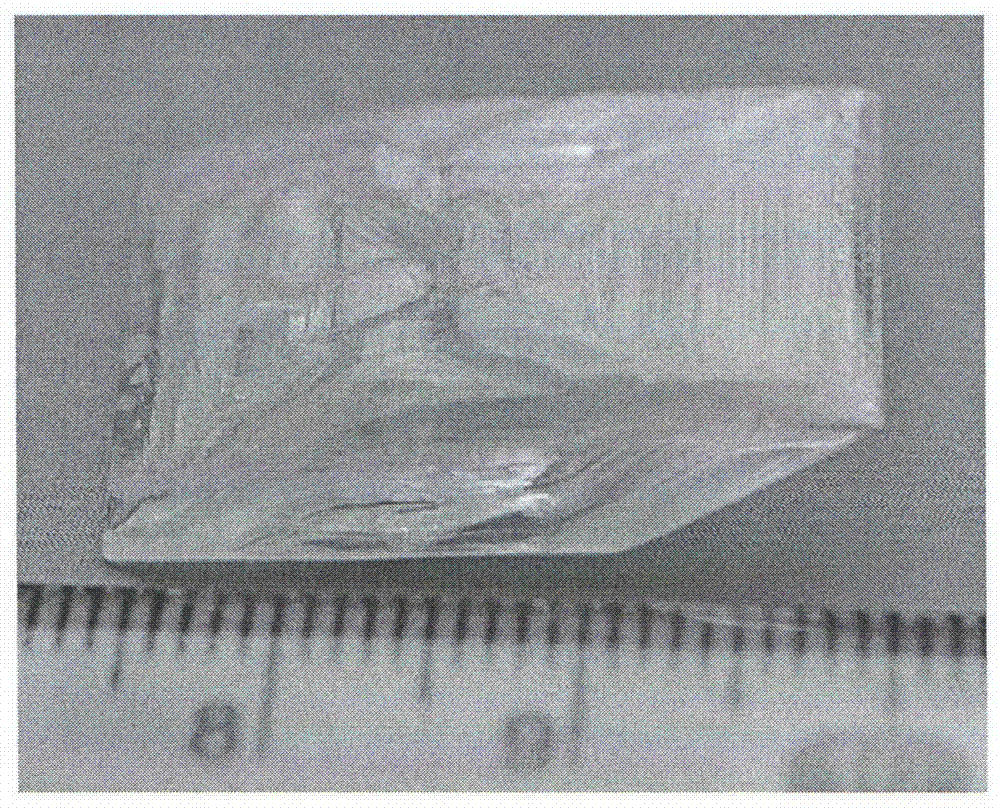

[0050] C, the crucible that fills the mixed melt that step a makes is placed in the crystal growth furnace, the Pb that the seed crystal that step b obtains is cut along the c-axis 2.14 OCl 2.28 The seed crystal is fixed on the lower end of the s...

Embodiment 3

[0053] Embodiment 3 (adopting melt method)

[0054] According to the reaction formula 1.14PbCl 2 +PbC 2 0 4 →Pb 2.14 OCl 2.28 +CO 2 ↑+CO↑ Synthesis of Pb 2.14 OCl 2.28 Compound, specific operation steps are carried out according to embodiment 1;

[0055] Preparation of Pb by Kyropoulos method 2.14 OCl 2.28 Crystal:

[0056] a, the synthesized Pb 2.14 OCl 2.28 The compound is put into a Φ100mm×100mm open platinum crucible and heated to melt, heated to a temperature of 600°C, and kept at a constant temperature for 25 hours to obtain a mixed melt of lead chlorate;

[0057] b. Preparation of lead chlorate seed crystals: Slowly lower the mixed melt obtained in step a to room temperature at a rate of 2° C. / h, and spontaneously crystallize to obtain lead chlorate seed crystals;

[0058] C, the crucible that fills the mixed melt that step a makes is placed in the crystal growth furnace, the Pb that the seed crystal that step b obtains is cut along the c-axis 2.14 OCl 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com