Process method for rubber tube vulcanization

A process method and technology of rubber tubes, which are applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problem of air bubbles or cracks in the bending area of rubber tubes, uneven heating of rubber tubes, and failure of rubber tube functions and durability to meet customer requirements and other problems, to achieve the effect of reducing air bubbles or cracking, and uniform heating inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The invention provides a process method for rubber tube vulcanization, the specific steps of the process method are:

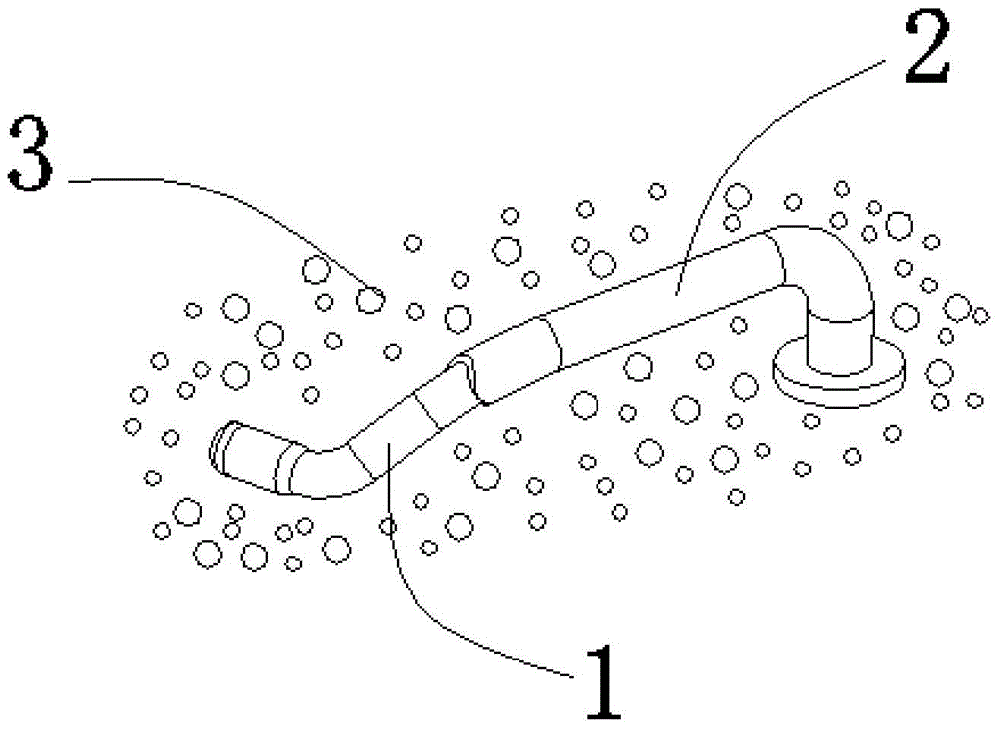

[0027] Step (1): Molding stage

[0028] Prepare the preformed rubber tube blank 2, and prepare the aluminum mandrel mold 1 corresponding to the caliber of the preformed rubber tube blank 2. There is a cutting allowance at both ends of the aluminum mandrel mold 1, and the aluminum core The surface of the rod mold 1 is evenly coated with a release agent; the corresponding preformed rubber tube blank 2 is inserted from the ring-free end of the aluminum mandrel mold 1 to complete the production of the sleeve mold tube blank. The temperature of the mandrel 1 can be cooled naturally, and the temperature is kept below 60°C, which effectively prevents the rubber tube blank 2 from being vulcanized by itself due to excessive heat. If the surface of the rubber tube blank 2 is scratched or damaged during the process, the damaged rubber tube will not undergo the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com