A vacuum microwave drying method for high temperature resistant communication cable insulation process and its drying recovery and reuse treatment device

A technology of vacuum microwave drying and communication cables, which is applied in the field of communication transmission to achieve the effects of thorough volatilization, uniform heating and strong penetrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

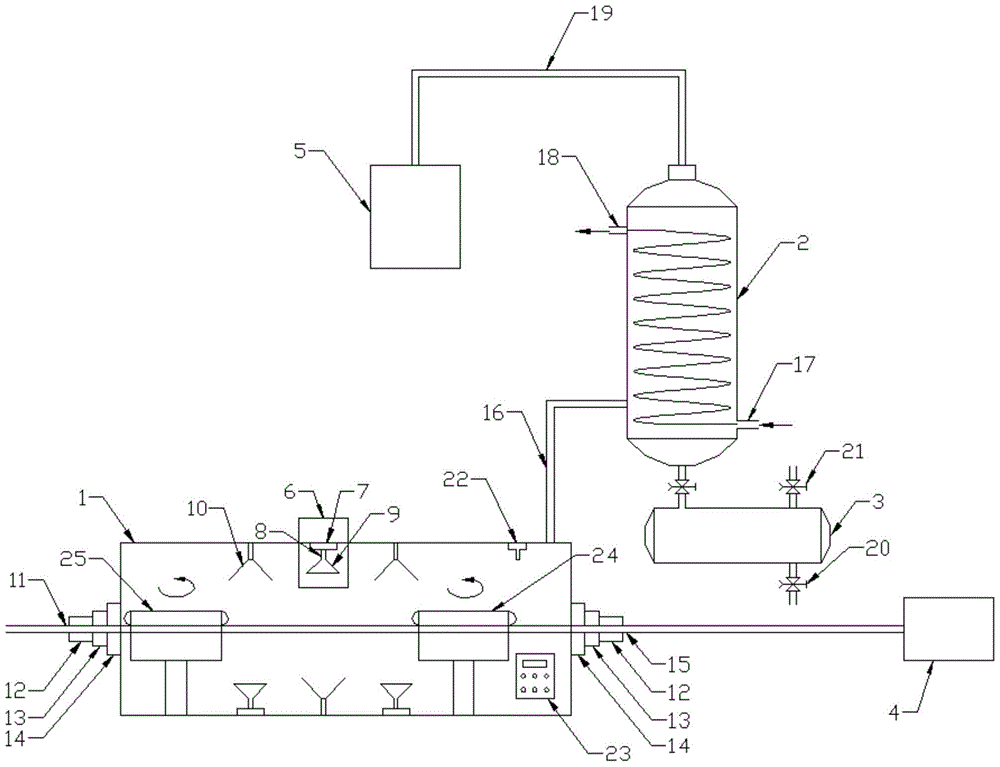

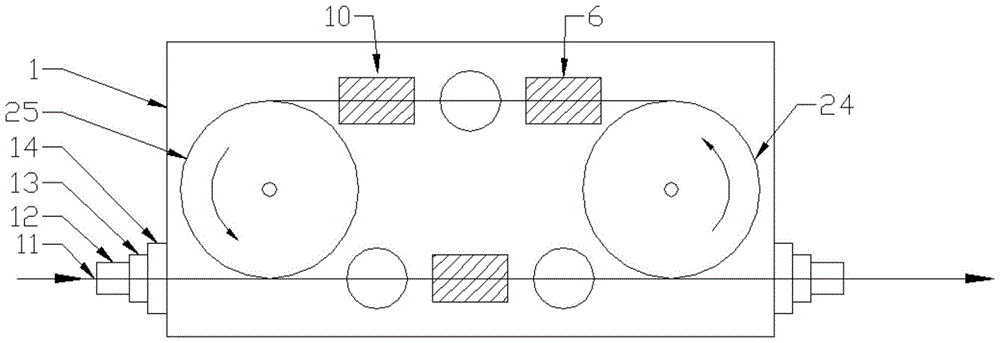

[0036] The present invention will be further described below in conjunction with accompanying drawing:

[0037] Below in conjunction with a specific implementation case, examples illustrate and help to further understand the present invention, but the specific details of the embodiment are only to illustrate the present invention, and do not represent all technical solutions under the present invention's conception, so it should not be interpreted as the general technology of the present invention For the limitation of the solution, in the eyes of some skilled persons, insubstantial changes that do not deviate from the concept of the present invention, such as simple changes or replacements with technical features having the same or similar technical effects, all belong to the protection scope of the present invention.

[0038] Such as figure 1 , figure 2 , a vacuum microwave drying recycling treatment device for high temperature resistant communication cable insulation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com