Rubber coating and cutting device for rubber v-belt wire billets

A cutting device and wire-belting technology, applied in belts, household utensils, metal processing, etc., can solve the problems of low cutting wire blank precision, low labor efficiency, precision cutting, etc., to improve processing quality and work efficiency, and reduce labor intensity , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the drawings.

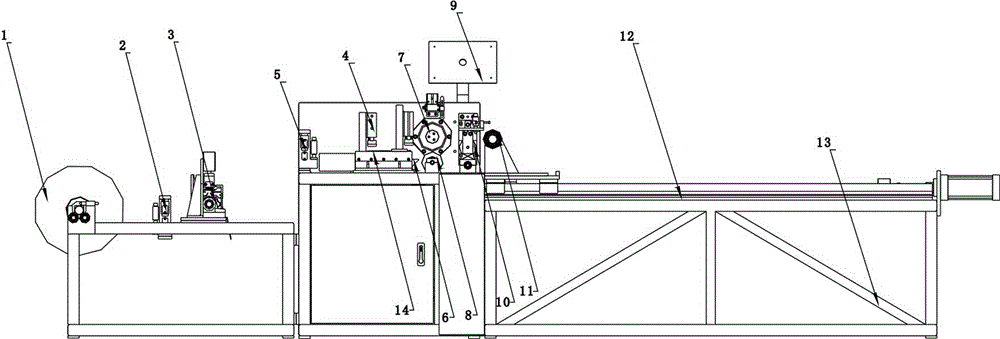

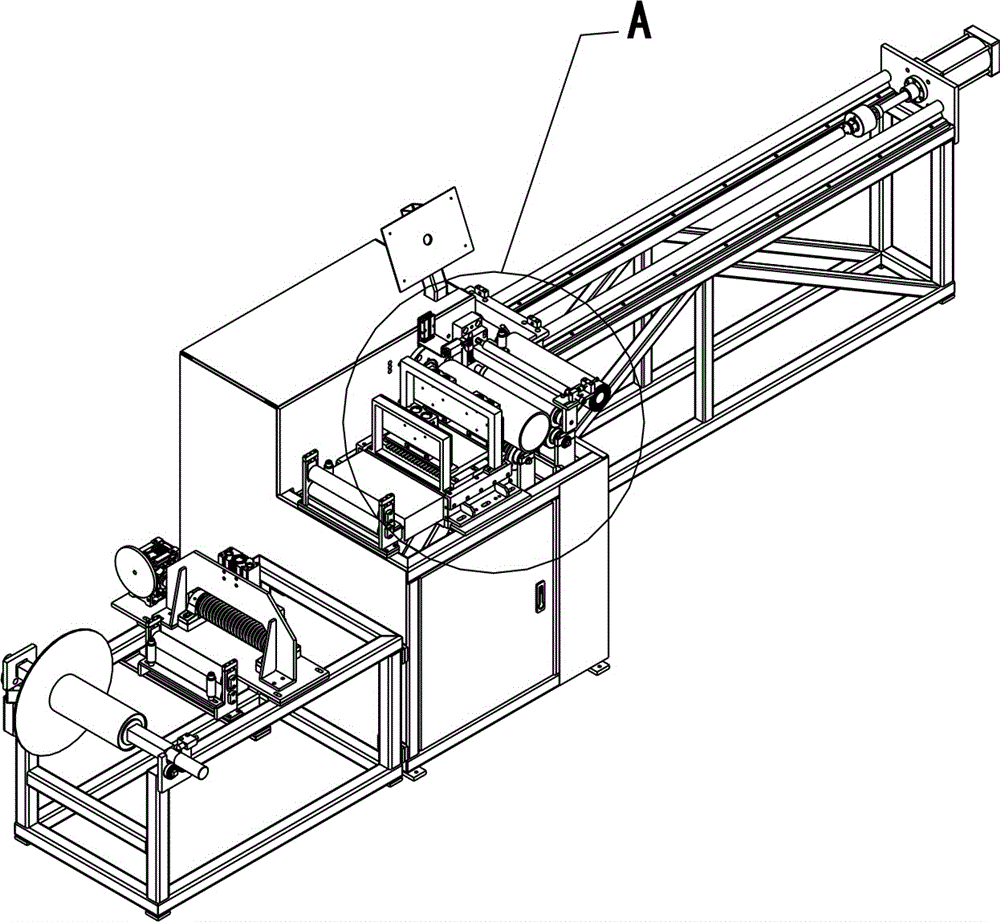

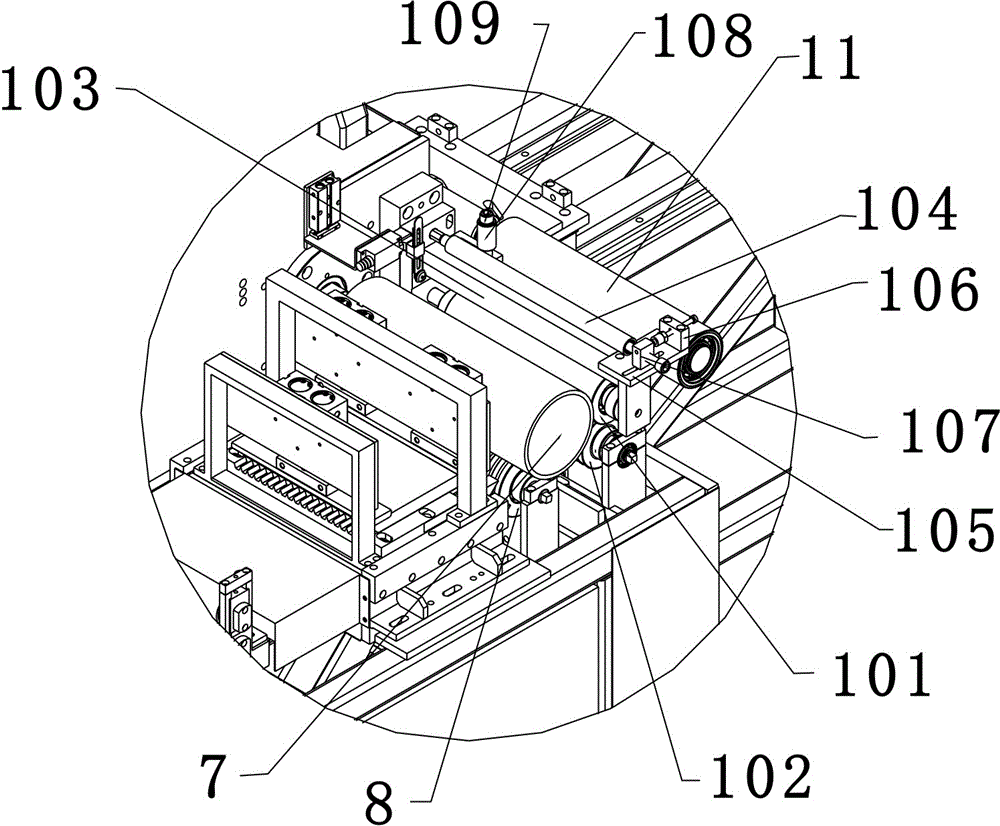

[0025] figure 1 It is a front view of a rubber V-belt coating and cutting device in an embodiment of the present invention, figure 2 Yes figure 1 The three-dimensional schematic diagram of the rubber coating and cutting device for the middle rubber V-belt. Combine figure 1 with figure 2 It can be seen that the rubber V-belt wire blank coating cutting device in this embodiment is a numerical control group cutting device, including a frame 13, and a primer lead-out device and a primer that are sequentially placed on the frame 13 from left to right. The conveying device, the bottom glue laminating and cutting mechanism also include a numerical control panel 9.

[0026] The frame 13 is installed on the ground to support the entire cutting device.

[0027] At the far left is the bottom glue export device, which in turn includes the bottom glue roll 1 installed on the frame 13, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com