Preparing method for low-purine tuna fillets

A production method and technology of tuna, which is applied in the field of tuna fillet, can solve the problems such as the undisclosed production method of low-purine tuna fillet, achieve the effects of low purine content, firm and elastic fish meat, and reduce fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

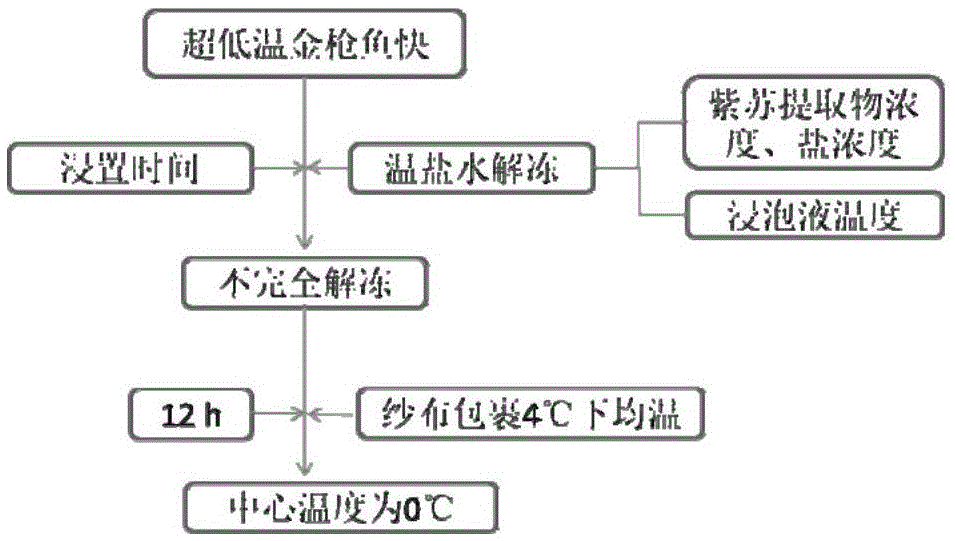

[0030] A kind of preparation method of low-purine tuna fillet, concrete steps are as follows:

[0031] (1) Preparation of perilla extract

[0032] Grind and homogenize perilla and add it to water together with salt to obtain a mixed solution. Extract the mixed solution at 200W at 40°C, 40KHz ultrasonic wave for 30min, filter through two layers of gauze to obtain the perilla extract, and store it at 4°C for later use; The mass concentration of salt in the mixed solution is 3%, and the mass concentration of perilla is 10%;

[0033] (2) Thawed tuna

[0034] Soak the frozen tuna in perilla extract at 40°C to thaw, soak for 105s, then put the tuna in a refrigerator at 4°C for uniform temperature treatment, the treatment time is 9 hours, so that the center temperature of the fish body drops to 0°C; The perilla extract infiltrates the tuna meat to dissolve free purines. At the same time, the thawing process is divided into two steps. During the uniform temperature process, the part...

Embodiment 2

[0040] The same as the above example 1, the difference is: in step (2), soak the frozen tuna in the perilla extract at 38°C to thaw, soak for 120s, and then put the tuna in a refrigerator at 3°C for uniform temperature treatment. The treatment time is 12 hours, and the temperature of the center of the fish body is reduced to -1°C; in step (3), the tuna is soaked in perilla extract at 4°C for 5 minutes.

Embodiment 3

[0042] Same as the above example 1, the difference is that in step (2), soak the frozen tuna in perilla extract at 42°C to thaw, soak for 90s, and then put the tuna in a refrigerator at 5°C for uniform temperature treatment. The treatment time is 6 hours, and the temperature of the center of the fish body is reduced to 1° C.; in step (3), the tuna is soaked in perilla extract at 4° C. for 10 minutes.

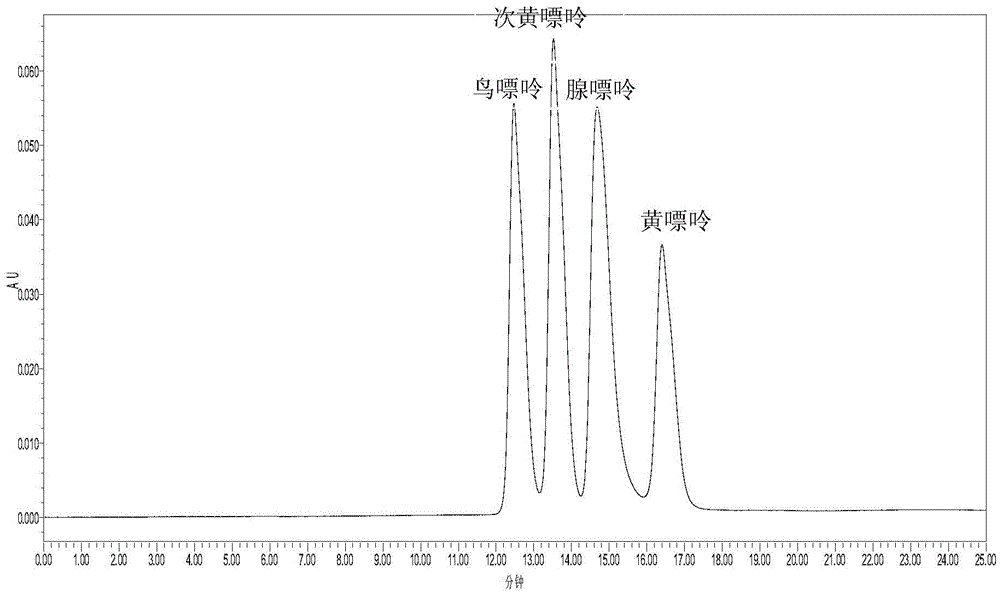

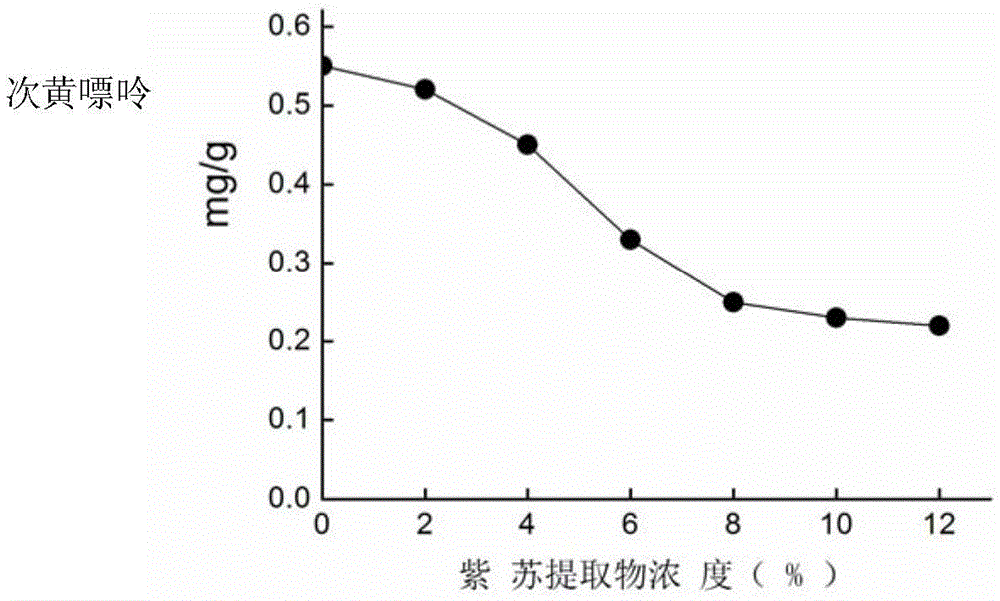

[0043] 3. Test analysis

[0044] 1. Effects of different technological processes on the purine content of tuna

[0045] According to the production process of tuna fillet (as described in the above-mentioned specific example 2), it is respectively set to use perilla extract only for thawing, only for soaking with perilla extract before cooking, for both thawing and soaking before cooking, and for the control group (the control group was thawed with 3% salt water, soaked in 3% salt water for 5 minutes before cooking), the free purines and total purines were measured respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com