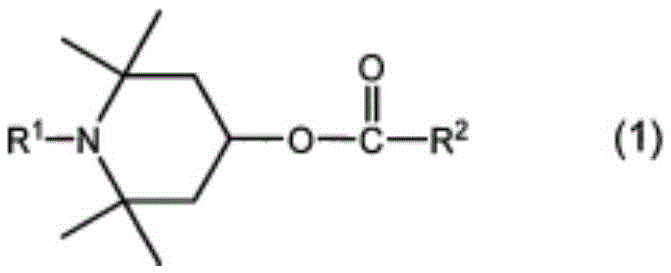

Light stabilizer composition and resin composition containing same

A light stabilizer and composition technology, applied in the direction of chemical change-inhibiting compositions, other chemical processes, chemical instruments and methods, etc., can solve the problems of easy adhesion on the surface, low molecular weight, volatilization, etc., and achieve excellent weather resistance , Excellent weather resistance and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-7 and comparative example 1-1~1-5

[0108] The hindered amine compound described in the following Table 1 or Table 2 was stirred at 40° C. for 20 minutes using an FM mixer (FM-20 type, manufactured by Japan Coke Co., Ltd.), whereby it was confirmed that the hindered amine compound was in a molten state, Then, according to the weight ratio (hindered amine compound / silicon dioxide) to reach the ratio of 30 / 70, 40 / 60, 50 / 50, add silicon dioxide under normal pressure to obtain the photostable compound prepared in each ratio. agent composition.

[0109] The following evaluation was performed about the photostabilizer composition obtained by the said method.

[0110] (1) traits

[0111] The obtained photostabilizer composition was put into a beaker and stirred so as to draw a circle on the bottom of the beaker with a glass rod, and then the properties were evaluated visually.

[0112] ◎: dry powder

[0113] ○: Moist powdery

[0114] △: Low stickiness, but lumpy

[0115] ×: Adhesive paste

[0116] In addition, th...

Embodiment 2-1

[0153] Embodiment 2-1 (stabilization of polypropylene)

[0154] Add polypropylene resin (MFR: 30g / 10min, density: 0.9g / cm 3 ) 70 parts by mass, ENGAGE 8100 10 parts by mass as an elastomer, 20 parts by mass of talc (trade name P-4 manufactured by Nippon Talc Co., Ltd.), tetrakis (3-4) as a phenolic antioxidant (3,5-di-tert-butyl-4-hydroxyphenyl)propionyloxymethyl)methane 0.05 parts by mass, tris(2,4-di-tert-butylphenyl)phosphite as phosphorus antioxidant 0.05 parts by mass, 0.05 parts by mass of calcium stearate, 3 parts by mass of beige masterbatch (product name: PPCM700V-118) manufactured by Tokyo Printingink Co., Ltd. as a pigment, and the light of Example 1-1 described in the following Table 1. 0.1 parts by mass of the stabilizer composition, mixed thoroughly, melted and kneaded at a resin temperature of 230°C while being discharged by a twin-screw extruder to make pellets, and injection molded at 230°C to obtain a test piece of 60mm×20mm×2mm piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com