A surge protector adopting a box-type fastening assembly structure

A technology of surge protector and assembly structure, applied in emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, circuit devices, etc. There are problems such as improvement and reduced reliability, so as to achieve the effect of improving utilization rate, improving power frequency tolerance, and avoiding wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

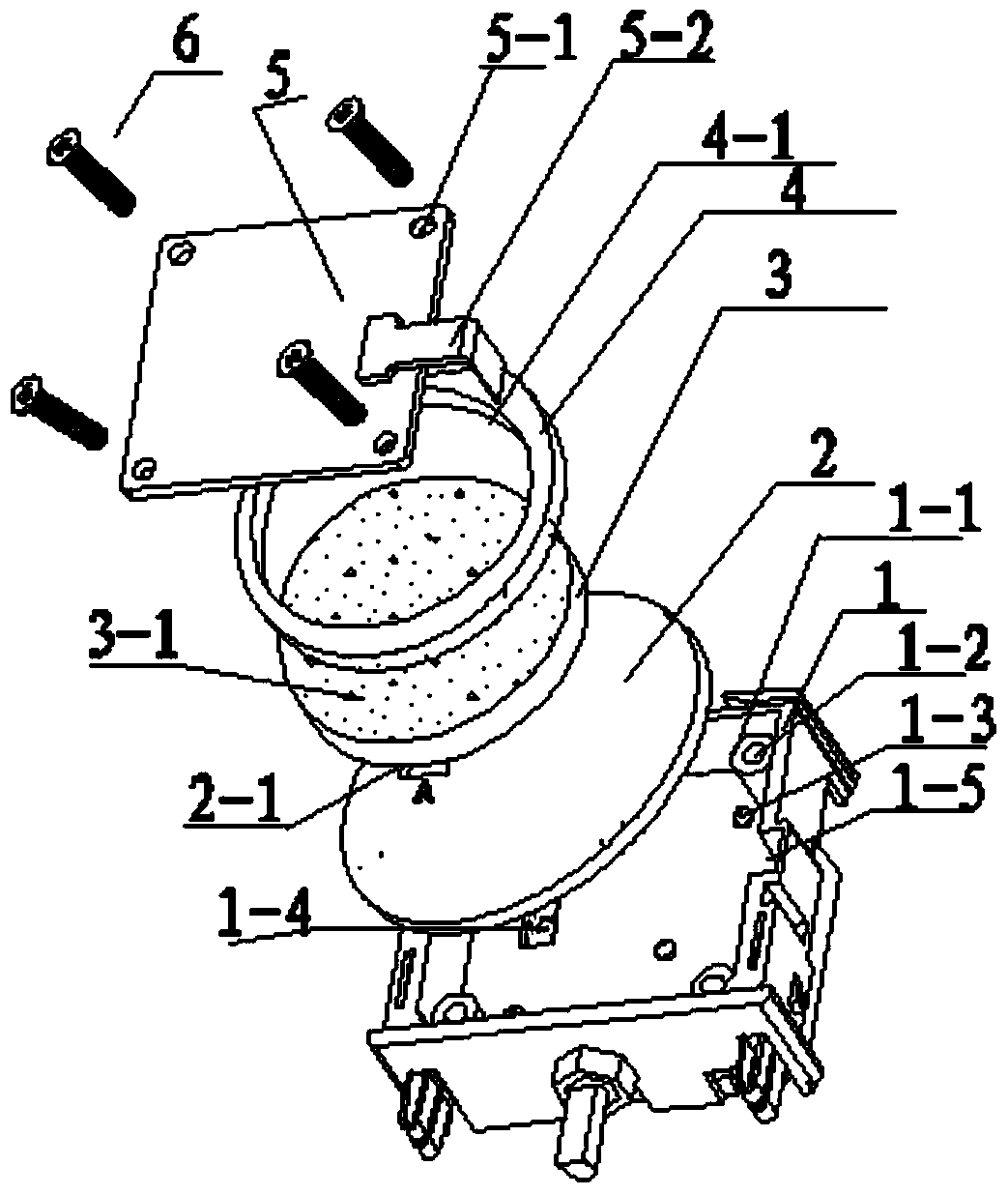

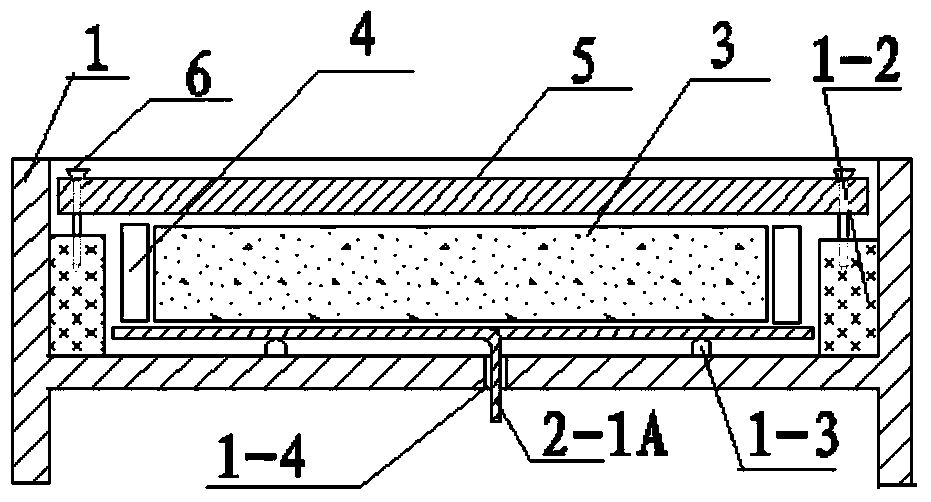

[0032] like Figure 1a , 1b As shown, the embodiment of the present invention provides a surge protector adopting a box-type fastening assembly structure, including an insulating box body 1, and the bottom of the insulating box body is located at about two-thirds of the total height of the insulating box body 1, so that The insulating box body is divided into two parts, the deep side of the box is installed with the MOV chip 3, and the shallow side of the box is installed with the tripping device. The four corners of the insulating box are provided with four hollow fixing studs 1-2, and the tripping electrode 2-1 of the tripping electrode sheet 2 extends out of the through hole 1-4 at the bottom of the insulating box 1, and the plane of the tripping electrode is insulated from the insulating box. The protruding points 1-3 at the bottom of the box are bonded, and the other side is bonded to one side of the MOV chip 3. One side of the upper electrode splint 5 is pressed on the o...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] like Figure 2a , 2b , 2c, the tripping electrode piece 2, MOV chip 3, and upper electrode splint 5 are fixed in the insulating box body 1 to form a box-type fastening assembly structure, and the top of the box-type fastening assembly structure is filled with Sealed with insulating adhesive layer 70, see Figure 2b . The bottom of the insulating box is further provided with four protruding points 1-3 which are evenly distributed and have the same height, and their heights are set to ensure the flow of the potting glue.

[0045] The insulating adhesive layer 70 is made of epoxy resin, phenolic resin, silicone material and the like.

[0046] The assembly process of the surge protector using the box-type fastening assembly structure of the above-mentioned embodiment of the present invention is as follows:

[0047] Place the side of the tripping electrode 2 with the pin 2-1 facing the bottom of the in...

Embodiment 3

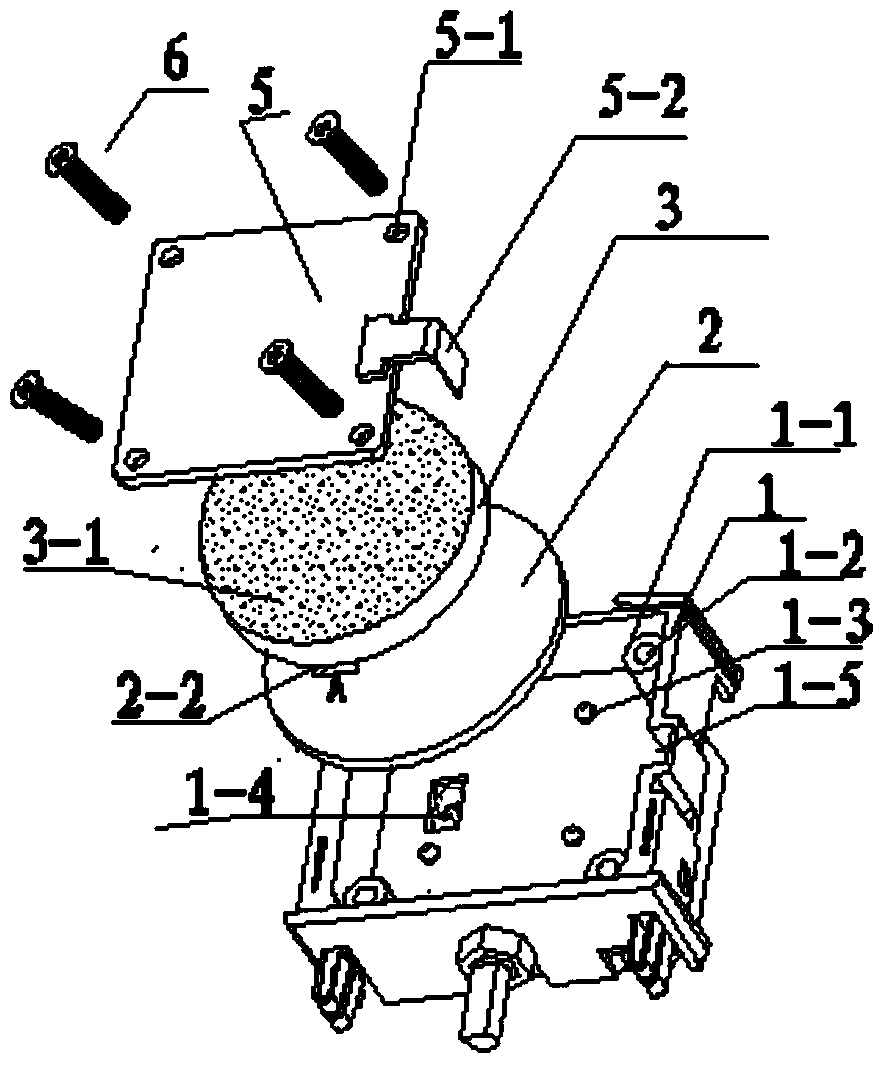

[0049] like Figure 4a , 4b As shown, the difference between this embodiment and the previous two examples is that the insulating box body 1 is not divided into two parts, and a deep insulating box body is used, which is assembled on the same side. The assembly process of the device is as follows: Align the notch on the two sides of the lead-out pin 2-2 of the tripping electrode piece 2 with the slot 1-6 on the insulating box body 1, and make the bottom surface of the tripping electrode piece 2 close to the insulating box The protruding point 1-3 at the bottom of the body 1 is inserted into the MOV chip, and the upper electrode splint 5 is covered, and the screw or rivet 6 is passed through the four corner through holes 5-1 of the upper electrode splint 5, and fastened to the four corners of the bottom of the insulating box body 1. In the hole of the stud 1-2, align the notch on both sides of the lead-out electrode 7 with the slot 1-7 on the insulating box body 1 and snap it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com