Engine camshaft bearing cover capable of preventing false mounting

A camshaft and bearing cover technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems affecting engine performance, camshaft locking, increasing camshaft friction loss, etc., to ensure performance and prevent errors The effect of simple decoration and design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

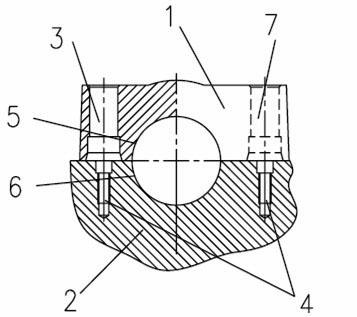

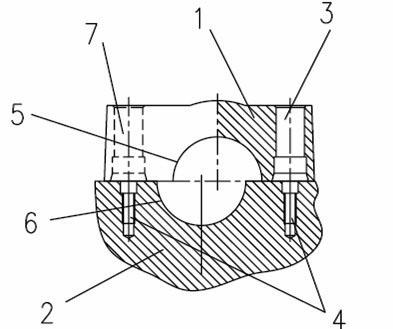

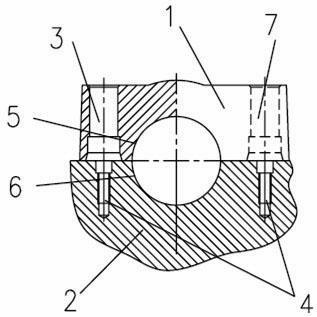

[0014] see figure 1 Shown is a situation where the engine camshaft bearing cap and the cylinder head that can prevent wrong installation are accurately matched. The camshaft bearing cap body 1 is provided with a first mounting hole 3 and a second mounting hole 7. The first mounting hole 3 Located on the left side of the upper part 5 of the camshaft mounting hole on the camshaft bearing cap body 1, the second mounting hole 7 is located on the right side of the upper half part 5 of the camshaft mounting hole on the camshaft bearing cap body 1 ; The distance between the centerline of the first mounting hole 3 and the centerline of the camshaft mounting hole is less than the distance between the centerline of the second mounting hole 7 and the centerline of the camshaft mounting hole;

[0015] The first mounting hole 3 and the second mounting hole 7 coincide corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com