Single photon imaging detector and manufacturing method thereof

A technology of imaging detector and manufacturing method, applied in radiation control devices and other directions, can solve problems such as poor coupling, and achieve the effects of low power consumption, low cost, and no cooling required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for manufacturing a single-photon imaging detector, including the following steps:

[0043]Step 110, preparing a silicon-based microchannel plate, the silicon-based microchannel plate is provided with an array of micro-through holes;

[0044] Specifically, a silicon wafer is used as the substrate, and a microhole array is formed on the substrate by silicon micro-via etching forming technology, and then a microchannel inner wall functional layer is prepared on the microhole array by chemical vapor deposition, forming Silicon-based microchannel plate; the above steps can ensure the high precision of the micropore size, and the size of the silicon-based microchannel plate can achieve a larger area, which is convenient for mass production;

[0045] Step 120, preparing CMOS imaging sensor array

[0046] Specifically, the step 120 includes the following steps:

[0047] Step 1201, forming a gradient-doped PinnedPhotodiode structure on the su...

Embodiment 2

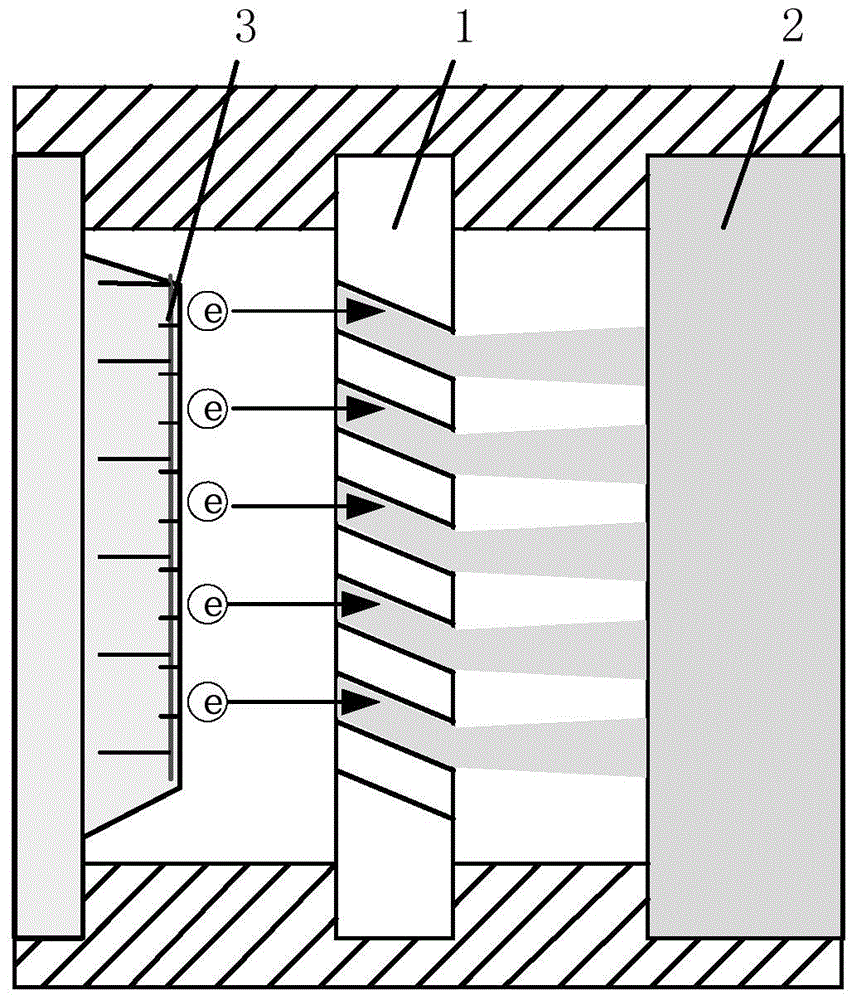

[0070] Such as figure 1 As shown, the present embodiment provides a fast single-photon imaging detector, obtained by the manufacturing method of Embodiment 1, comprising a silicon-based microchannel plate 1, a CMOS imaging sensor array 2 and a photocathode 3, the silicon-based microchannel plate 1 is provided with a micro-via array, and the CMOS imaging sensor array 2 is an array of several imaging sensors 21 arranged on a silicon substrate, and the photocathode 3 is translucent; when light irradiates the translucent photoelectric On the cathode, the electric field between the photocathode 3 and the silicon-based microchannel plate 1 pushes the electrons released from the surface of the photocathode 3 into the silicon-based microchannel plate 1, and the silicon-based microchannel plate 1 will to 10 4 -10 8 The number of electrons is amplified by an order of magnitude, and the magnification is controlled by adjusting the amplification voltage at both ends of the silicon-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com